About a week ago I finally got my new Whelen 900 Series Halogen lights installed on each side, but I haven't had time to write it up until now.

Since my ambulance is a 1993 model, it had the much older 97 Series lights on it. According to all the 'experts', the 900s are suppose to be a drop in replacement but they aren't, at least not in my case. The shape of the hole is the main problem and the sloppy work of the person installing them originally, is the other problem.

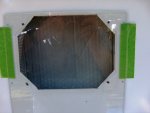

The 97s use a hole shaped like this:

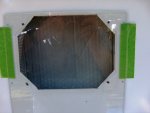

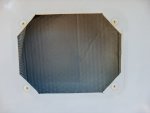

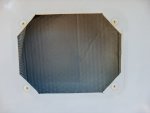

But the 900s require a hole shaped like this:

![sshot-2016-05-22-[1].jpg sshot-2016-05-22-[1].jpg](https://forum.expeditionportal.com/data/attachments/267/267311-fbcf11809c4fc57202730d6deb990acb.jpg?hash=-88RgJxPxX) http://www.whelen.com/install/136/13627.pdf

http://www.whelen.com/install/136/13627.pdf

I also had a set of chrome bezels cleaned up and ready to install along with the lights, but discovered they would not work without serious modifications due to the close proximity of the four warning lights to the corner extrusions and compartments. The scene/work lights would work fine, but then they wouldn't match, so I just left them off for now.

Basically, these are the steps I used to make them fit:

1. I started by creating a template made out of clear Lexan, so I could see what was going on underneath.

2. Now I could see the alignment of the existing mounting holes in relation to the accurate mounting holes, and the same with the cut out section.

3. Once I had the mounting holes accurately re-drilled, the lights still wouldn’t sit in the holes like they should. The new lights came with nylon inserts to put in the holes for the screws to anchor into.

4. I compared and measured the 900’s (black) with my old 97’s (gray) and the reflector bowl height was the same, but the 900 width was a little smaller, which should have made them easier to fit.

5. The 900’s have 2 nipples on the back of the reflector, one in the top right, and one in the lower left corner, similar to what you see on the halogen automobile headlights for draining. These things stuck out almost 3/8” and looked as if a drain tube could be attached to the lower one.

6. If I had the 900 pattern cut outs, these nipples would have cleared, but since I wasn’t looking forward to cutting about ¼” all the way around each opening x 8 while standing on a ladder, I chose to just cut the plastic nipples off flush with the reflector. After that, they fit fine.

7. Right now, I’m leaving them open so the light housings can breathe, but if I notice any water in there, that means the seal is leaking and will need to be reseated. If that doesn’t do it, I’ll tape the holes up.

![sshot-2016-05-22-[1].jpg sshot-2016-05-22-[1].jpg](https://forum.expeditionportal.com/data/attachments/267/267311-fbcf11809c4fc57202730d6deb990acb.jpg?hash=-88RgJxPxX)