You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project: Doitall Dodge

- Thread starter Metcalf

- Start date

alexrex20

Explorer

Super secret dirty spy pic....

you traded your truck for an Altima Coupe?!

Teleturn,

What is the length of the drag-link ( TRE center to TRE center )?

The drag link is 41.5" from center to center

Metcalf

Expedition Leader

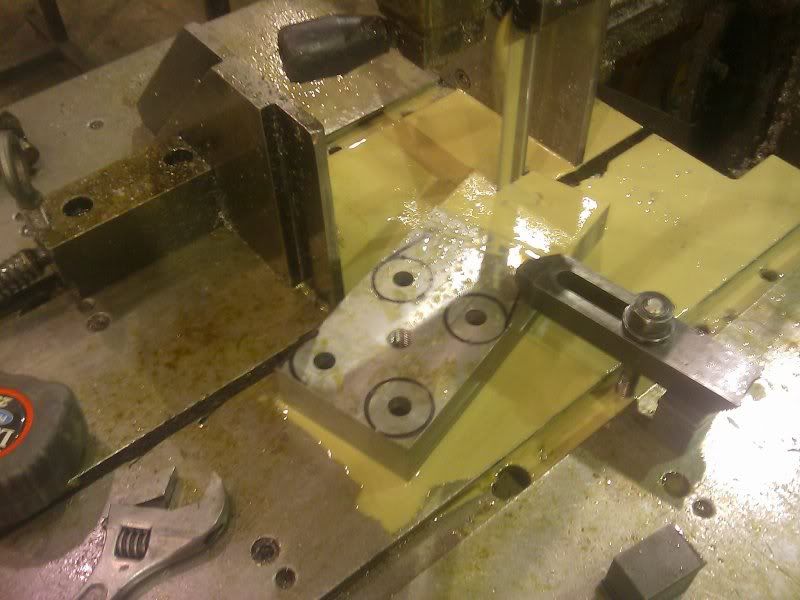

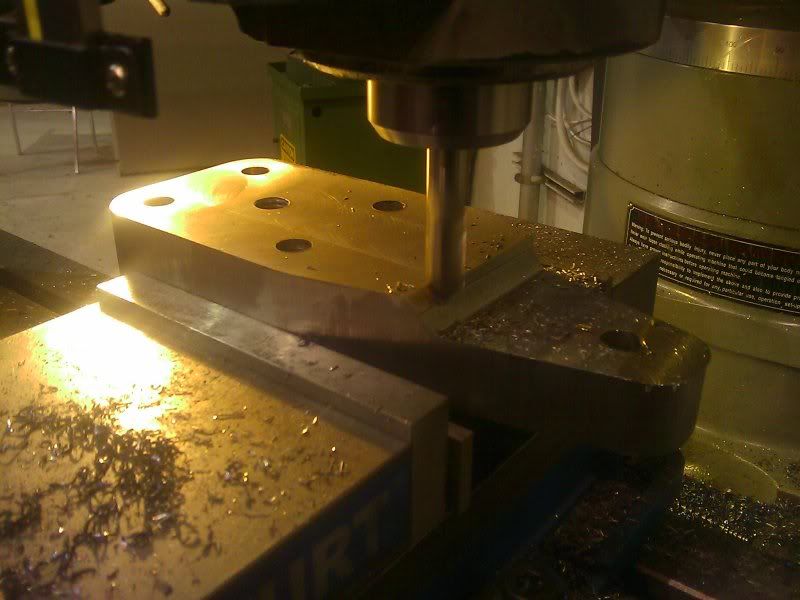

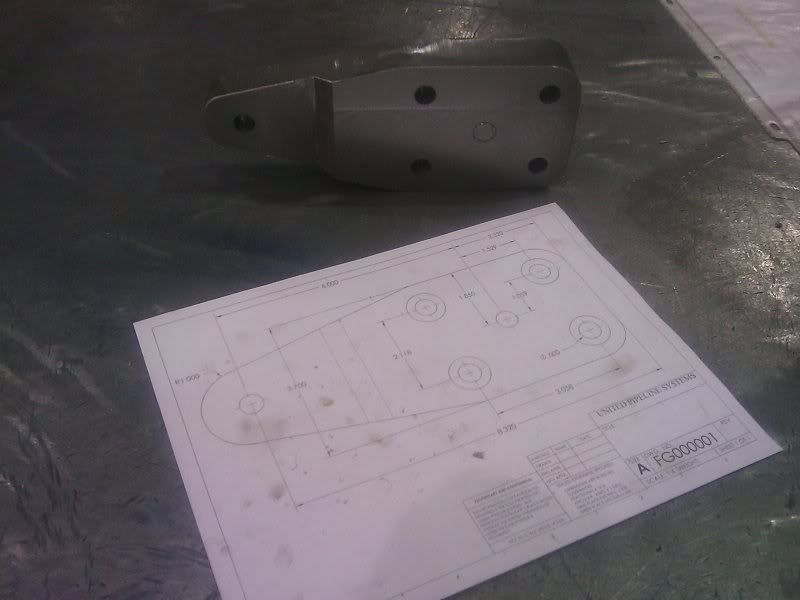

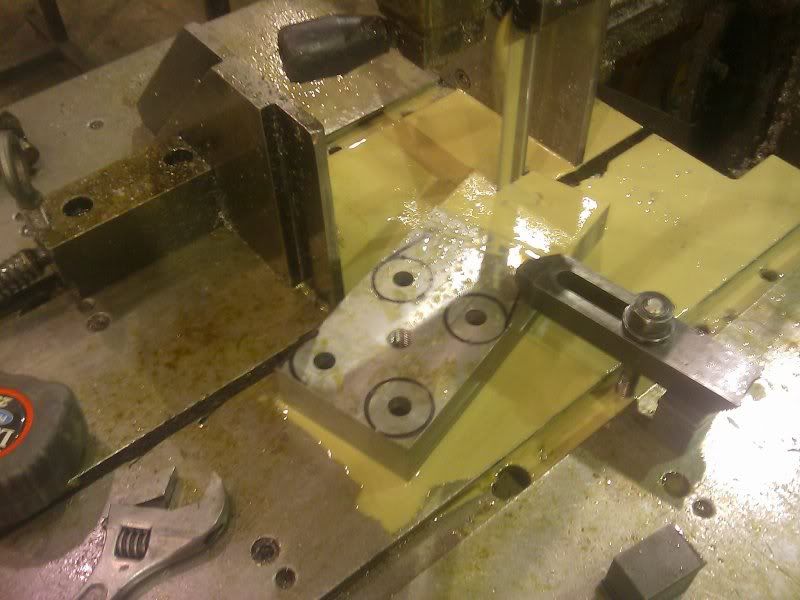

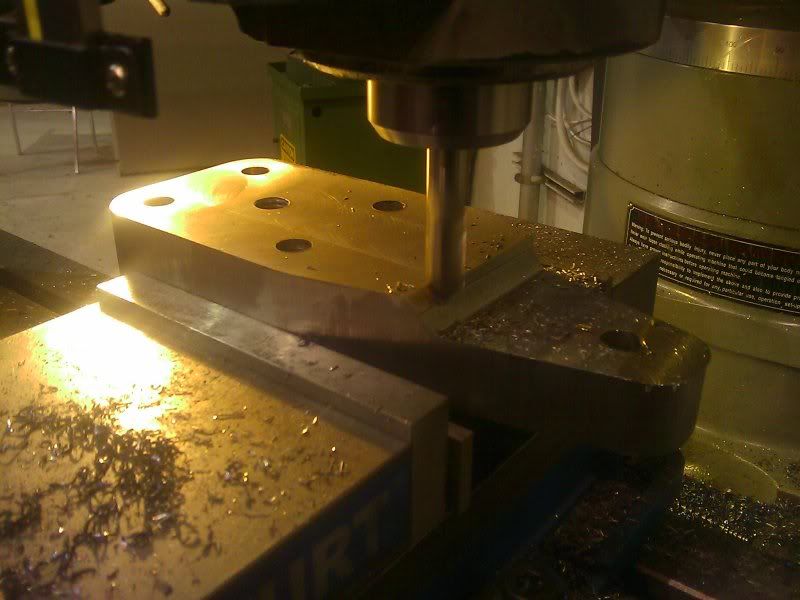

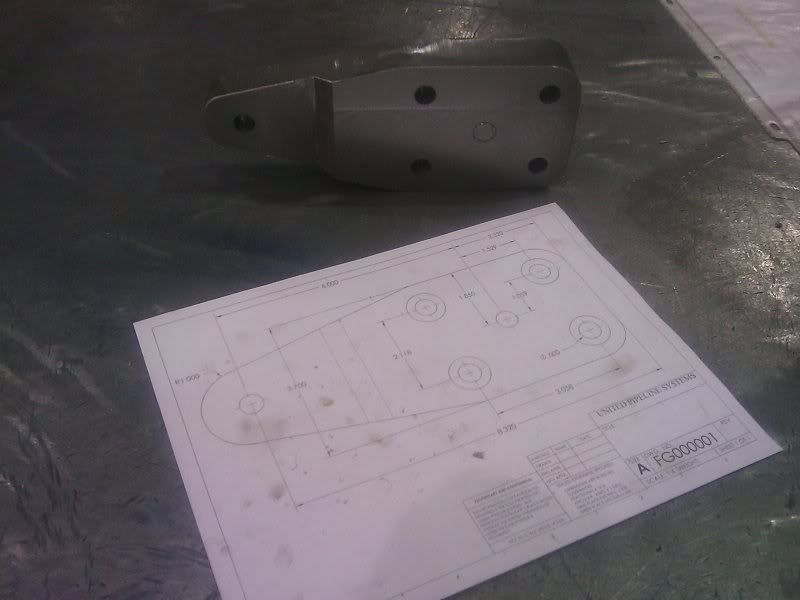

I spent a little time in the machine shop after work. The arm isn't done yet, but I only have about 3 hours in it. I need to order a tapered reamer to do the TRE hole. I also need to put the 60 taper on the 4 mounting holes. I decided to make a 'springless' design also. I still have a little work to do on the adjuster for the kingpin adjuster.

First I found a nice big chunk of cold finish steel in the scrap bin. I cut it to length in the bandsaw. Then I set it in the mill and started to square it up. I had to reduce the with by about 0.300. That took a little bit, but not too long with the fly cutter.

Then I laid it on its side and fly cut the face.

I cleaned up the other edge and used the DRO to find a quick center of the arm. I then centered and drilled the two main holes. One for the TRE, one for the 'springless' adjuster.

I then centered and drilled the 4 mounting holes. The DRO makes stuff like this pretty easy. I then tapped the 'springless' mounting hole before I pulled it out of the vise. I love big tap handles.....

Next I rough cut off some extra material to make the arm look a little bit better and be a little bit lighter.....

I then finished the 'step' on the arm once I spent a little time on the sander rounding the profile a bit. I brought the thickness of the arm down to 1.00" thick where the TRE mounts. The arm is 1.5" tall to clear my taller spring pack...and any future spring pack.

I did a 45 degree taper on the step to help with the stress riser at the thickness change. Plus, it looks better.

That is about as far as I got tonight. I started making the 'springless' adjuster. I need to mill some flats on the 'stud' I made so you can adjust the tension. I also need to make a nice little 2" washer to fit over the nylon bushing in the knuckle.

I will probably order my reamer tomorrow....

More to come.....

First I found a nice big chunk of cold finish steel in the scrap bin. I cut it to length in the bandsaw. Then I set it in the mill and started to square it up. I had to reduce the with by about 0.300. That took a little bit, but not too long with the fly cutter.

Then I laid it on its side and fly cut the face.

I cleaned up the other edge and used the DRO to find a quick center of the arm. I then centered and drilled the two main holes. One for the TRE, one for the 'springless' adjuster.

I then centered and drilled the 4 mounting holes. The DRO makes stuff like this pretty easy. I then tapped the 'springless' mounting hole before I pulled it out of the vise. I love big tap handles.....

Next I rough cut off some extra material to make the arm look a little bit better and be a little bit lighter.....

I then finished the 'step' on the arm once I spent a little time on the sander rounding the profile a bit. I brought the thickness of the arm down to 1.00" thick where the TRE mounts. The arm is 1.5" tall to clear my taller spring pack...and any future spring pack.

I did a 45 degree taper on the step to help with the stress riser at the thickness change. Plus, it looks better.

That is about as far as I got tonight. I started making the 'springless' adjuster. I need to mill some flats on the 'stud' I made so you can adjust the tension. I also need to make a nice little 2" washer to fit over the nylon bushing in the knuckle.

I will probably order my reamer tomorrow....

More to come.....

The steering arm looks great. If I had access to a mill I would be able to make so many more parts.

Couple questions.....

Are you going to do high steer or just cross over? I am guessing cross over because there is only one TRE hole on the arm.

If you are doing crossover and it is springless on the passenger side kingpin will there be any issues having the spring on the drivers side?

Just a thought. I have rebuilt many kingpins due to death wobble and I know it only takes a slight modification for it all to go wrong.

I am really interrested in the springless adjuster......I would like to go that route on my truck

Couple questions.....

Are you going to do high steer or just cross over? I am guessing cross over because there is only one TRE hole on the arm.

If you are doing crossover and it is springless on the passenger side kingpin will there be any issues having the spring on the drivers side?

Just a thought. I have rebuilt many kingpins due to death wobble and I know it only takes a slight modification for it all to go wrong.

I am really interrested in the springless adjuster......I would like to go that route on my truck

PNWDad

Dad in the streets, Daddy in the sheets

When I did my crossover steering a few years ago, my crossmember only required about an inch to be ground off the front part. I have never had a problem with it as of yet *knock on wood*.

I am using 6" springs and relocated shackle mounts, so about 8" lift.

I am using 6" springs and relocated shackle mounts, so about 8" lift.

Metcalf

Expedition Leader

I am just doing crossover, not hi-steer. I just don't think I have the room for it without much lift.

Springless on one side shouldn't matter. I will most likely build another top cap for the other side when I get a chance.

The drag link is going to have to be bent a lot to clear the crossmember, springs, etc....I only have about 2" of 'lift' in front, maybe less.

Having a lot of tools at work saves me a lot of money. So far my arm cost me nothing. I will have a bit in a tapered reamer but I will be able to use that over and over for other projects too. The WJ pitman arm was only $22 shipped, new. I need to open up the taper in that one also....so bonus on buying the tool again.

I think I am going to single point the adapters for the TREs in the drag link. I am going to make a double adjuster on one side also so I can change the length without having to take the bar off ( since its going to have to be bent )

Springless on one side shouldn't matter. I will most likely build another top cap for the other side when I get a chance.

The drag link is going to have to be bent a lot to clear the crossmember, springs, etc....I only have about 2" of 'lift' in front, maybe less.

Having a lot of tools at work saves me a lot of money. So far my arm cost me nothing. I will have a bit in a tapered reamer but I will be able to use that over and over for other projects too. The WJ pitman arm was only $22 shipped, new. I need to open up the taper in that one also....so bonus on buying the tool again.

I think I am going to single point the adapters for the TREs in the drag link. I am going to make a double adjuster on one side also so I can change the length without having to take the bar off ( since its going to have to be bent )

Metcalf

Expedition Leader

Boy, did I get my butt kicked today.........

The Dodge froze up on the way to work this morning when it was -15

degrees out. There was water in the fuel filter/ water

separator that froze up. The fuel was still good, but it couldn't get

through the filter because of the frozen water in the pleats I guess.

I roll the truck to a stop, then I have to starter the truck up off

the road ( a vote for manual transmissions and big batteries ). I took

off the frozen fuel filter once I figured it out. Prime the new filter

with the manual lever on the fuel pump. Still won't start. Check for

fuel...yup....its flowing to the injector pump. The injector lines are

full of air and are basically not working. I crack the heads of the

injectors and try and blow the air out. I get the truck started, but

as soon as I pull out in the road it does it again. Dead engine. I get

the truck mostly off the road again. Crack the injector lines again,

double check everything else. It starts up, runs for a minute and

dies. Try again. It runs again. I jump in trying to get it to work.

Nope, stalls again, right in the middle of the road. The battery is

toast. I try to stater it up off the road....nope. Battery was low

enough that the blinkers where not working.....

There is me standing behind my truck directing traffic around the

truck. I made a call to a guy at work to come help. He shows up

shortly after the cop did The cop was nice enough, he helped with

The cop was nice enough, he helped with

traffic. I thought I had my tow strap in the back....nope....its in

the Willys. The guy from work didn't have a chain or strap. I found

two 1" webbing tie downs in the back of the dodge. I rig those

together and see if we can move the truck off the road. After about

2-3 tries that worked.....:Wow1:

The truck is now off the road in a little parking lot. I get some

jumpers on the battery and recheck the fuel system again. I crack all

the injectors again. Once the battery is charged enough to turn the

truck over. The friend informing me that I still have bubbles coming

out the injectors.......

FINALLY all the air works its way out. I am able to start the truck

and it runs at least enough to pull it into a parking space. I let it

run for 10-15 minutes or so. Still no stalling. Then I hold it at 2000rpm or so, again no stalling.

I don't trust it though, no tow strap and a busy part of town between

me and work. So I have my buddy from work run me over to the high

school so I can borrow the Jetta from the misses. Then its off to the parts house forsome fuel treatment ( and a spare fuel pump ) Then back over to where the dodge is parked.

It starts back up right away and idles just fine....throttles just

fine, etc. I drove it around the parking lot a bit. Seems fine. I have

both vehicles though. So I let the truck come up to temp after adding

a half bottle of 911 treatment and a half bottle of regular treatment.

It doesn't miss a beat. I aired up some low tires with the 12V

compressor while I waited.

Then I drove the Jetta home, let the dogs out since they where inside

since it was -15F. I took a shower because I smelled like diesel. That

freaking hurt. I guess I didn't notice that I had a little bit of

frost bite on my back where my jackets where ridding up when I was

working on the truck. I got a nice little white and red splotch on my

back. The warm water in the shower really made it hurt.

Then back to town with the tow strap for the Dodge just in case....of

course that was after kicking it out of the 2 feet of snow in the back

of the Willys.

I didn't get to work till like 1:30 so I just took the entire day.

Truck started back up when I tried it again. I killed the afternoon napping on the couch and phoned a friend to relay the story ( and plan a Rubicon trip in early august! ). Then I finally drove back in and had the misses follow me home when she had a break in parent teacher conferences. I flogged the truck on the way home......it didn't miss a beat. Ran just like it always does.

Anyways......

Lessons learned....

-Keep a dedicated tow strap in every vehicle 100% of the time.

-Don't think anyone is going to stop and help. A 150 cars must have driven buy. ONE stopped for a sec....but couldn't help at all.

-Keep a dedicated LONG HEAVY pair of jumper cables in every vehicle 100% of the time.

-Keep a spare fuel filter if you drive a Diesel. That was worth its weight in gold. I would have been up a creek without it.

-Keep a bottle of 911 fuel treatment in a diesel.

-Keep a bottle of regular anti-gel AND USE IT at the the pump. I had slacked off this year on that.

-Keep tools in the truck ( REALLY glad I have tools in the truck ). You need a filter wrench, a 17mm end wrench, and a 10mm end wrench if you have to go through this like I did.

-Keep a heavy spare coat, boots, and maybe some overalls in the truck. I never really felt cold...but the frostbite sucks, OUCH!

If this would have been in a remote area. I would have most likely been in a much worse situation. It would have been fire starting time. The dead battery would have been hard to deal with. I still like the idea of a BIG solar panel on the top of the camper shell. Even if it took a day to charge the battery, that would be worth something. A small generator could also work, and might not be a bad idea for cold weather. It could be used to warm the engine with the block heater....charge a battery....etc.

-I will probably add a bottle of kerosene also. That works well for thinning fuel or topping a filter off. It also keeps forever.

-Note: I did fill up with 18 gallons of fuel the day before at a non-regular station. It was WAY cold this morning...and I had already burned 3-4gallons out of the tank, but that was the only thing out of the ordinary other than the -15F temps.

Oh....I ordered my reamer yesterday so the steering project should move into gear next week.

Stay warm, Stay safe!

The Dodge froze up on the way to work this morning when it was -15

degrees out. There was water in the fuel filter/ water

separator that froze up. The fuel was still good, but it couldn't get

through the filter because of the frozen water in the pleats I guess.

I roll the truck to a stop, then I have to starter the truck up off

the road ( a vote for manual transmissions and big batteries ). I took

off the frozen fuel filter once I figured it out. Prime the new filter

with the manual lever on the fuel pump. Still won't start. Check for

fuel...yup....its flowing to the injector pump. The injector lines are

full of air and are basically not working. I crack the heads of the

injectors and try and blow the air out. I get the truck started, but

as soon as I pull out in the road it does it again. Dead engine. I get

the truck mostly off the road again. Crack the injector lines again,

double check everything else. It starts up, runs for a minute and

dies. Try again. It runs again. I jump in trying to get it to work.

Nope, stalls again, right in the middle of the road. The battery is

toast. I try to stater it up off the road....nope. Battery was low

enough that the blinkers where not working.....

There is me standing behind my truck directing traffic around the

truck. I made a call to a guy at work to come help. He shows up

shortly after the cop did

traffic. I thought I had my tow strap in the back....nope....its in

the Willys. The guy from work didn't have a chain or strap. I found

two 1" webbing tie downs in the back of the dodge. I rig those

together and see if we can move the truck off the road. After about

2-3 tries that worked.....:Wow1:

The truck is now off the road in a little parking lot. I get some

jumpers on the battery and recheck the fuel system again. I crack all

the injectors again. Once the battery is charged enough to turn the

truck over. The friend informing me that I still have bubbles coming

out the injectors.......

FINALLY all the air works its way out. I am able to start the truck

and it runs at least enough to pull it into a parking space. I let it

run for 10-15 minutes or so. Still no stalling. Then I hold it at 2000rpm or so, again no stalling.

I don't trust it though, no tow strap and a busy part of town between

me and work. So I have my buddy from work run me over to the high

school so I can borrow the Jetta from the misses. Then its off to the parts house forsome fuel treatment ( and a spare fuel pump ) Then back over to where the dodge is parked.

It starts back up right away and idles just fine....throttles just

fine, etc. I drove it around the parking lot a bit. Seems fine. I have

both vehicles though. So I let the truck come up to temp after adding

a half bottle of 911 treatment and a half bottle of regular treatment.

It doesn't miss a beat. I aired up some low tires with the 12V

compressor while I waited.

Then I drove the Jetta home, let the dogs out since they where inside

since it was -15F. I took a shower because I smelled like diesel. That

freaking hurt. I guess I didn't notice that I had a little bit of

frost bite on my back where my jackets where ridding up when I was

working on the truck. I got a nice little white and red splotch on my

back. The warm water in the shower really made it hurt.

Then back to town with the tow strap for the Dodge just in case....of

course that was after kicking it out of the 2 feet of snow in the back

of the Willys.

I didn't get to work till like 1:30 so I just took the entire day.

Truck started back up when I tried it again. I killed the afternoon napping on the couch and phoned a friend to relay the story ( and plan a Rubicon trip in early august! ). Then I finally drove back in and had the misses follow me home when she had a break in parent teacher conferences. I flogged the truck on the way home......it didn't miss a beat. Ran just like it always does.

Anyways......

Lessons learned....

-Keep a dedicated tow strap in every vehicle 100% of the time.

-Don't think anyone is going to stop and help. A 150 cars must have driven buy. ONE stopped for a sec....but couldn't help at all.

-Keep a dedicated LONG HEAVY pair of jumper cables in every vehicle 100% of the time.

-Keep a spare fuel filter if you drive a Diesel. That was worth its weight in gold. I would have been up a creek without it.

-Keep a bottle of 911 fuel treatment in a diesel.

-Keep a bottle of regular anti-gel AND USE IT at the the pump. I had slacked off this year on that.

-Keep tools in the truck ( REALLY glad I have tools in the truck ). You need a filter wrench, a 17mm end wrench, and a 10mm end wrench if you have to go through this like I did.

-Keep a heavy spare coat, boots, and maybe some overalls in the truck. I never really felt cold...but the frostbite sucks, OUCH!

If this would have been in a remote area. I would have most likely been in a much worse situation. It would have been fire starting time. The dead battery would have been hard to deal with. I still like the idea of a BIG solar panel on the top of the camper shell. Even if it took a day to charge the battery, that would be worth something. A small generator could also work, and might not be a bad idea for cold weather. It could be used to warm the engine with the block heater....charge a battery....etc.

-I will probably add a bottle of kerosene also. That works well for thinning fuel or topping a filter off. It also keeps forever.

-Note: I did fill up with 18 gallons of fuel the day before at a non-regular station. It was WAY cold this morning...and I had already burned 3-4gallons out of the tank, but that was the only thing out of the ordinary other than the -15F temps.

Oh....I ordered my reamer yesterday so the steering project should move into gear next week.

Stay warm, Stay safe!

jdholder

Explorer

So glad this happened where you could get help!! Lessons learned and I hope the frostbite wasn't too bad.

I don't live in cold weather, but when I had a diesel and was heading to the mountains (cold, but not -15) I would ALWAYS use HEAT or 911 or Stanadyne additive to keep the fuel from gelling. Once it's gelled up, it's TOUGH to get it going - as you know!

I don't live in cold weather, but when I had a diesel and was heading to the mountains (cold, but not -15) I would ALWAYS use HEAT or 911 or Stanadyne additive to keep the fuel from gelling. Once it's gelled up, it's TOUGH to get it going - as you know!

Sounds like a hell of a day! I forgot to plug my diesel in, so I didn't even bother trying to start it this morning. I opted for the motorcycle and it was -7 outside. Let's just say I had an ice cream headache the whole way to work.

Hopefully I'll be moving to the Durango area soon. Once I'm there, you can give me a call anytime if you need help.

Oh by the way I got my tires on the truck. They look sweet and ride like crap. Exactly what I was going for. I'll post pics soon....

Hopefully I'll be moving to the Durango area soon. Once I'm there, you can give me a call anytime if you need help.

Oh by the way I got my tires on the truck. They look sweet and ride like crap. Exactly what I was going for. I'll post pics soon....

Uh oh....another expo guy thats a dodge head in Durango...watch out.

Let me know when you get to town or if you need any help moving or looking for a place.

Thanks for the offer...waiting to find out if I got the job....

I'll keep you updated