You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project T100: "Baja Explorer Ver. 2"

- Thread starter G100

- Start date

Haggis

Appalachian Ridgerunner

That's a nice T-100. A buddy of mine just picked up it's twin a couple of weeks ago, though his came already lifted.

As far as this project...

As far as this project...

...if you can get it working you'll love it! It's the coolest feature on our Tundra and is known as The Airlock. Running with the cap on we have the kids access the travelling cooler for cold drinks and snacks as the cooler sits on top of our watertank in the front of the bed. With the cap off and running the backroads it's all windows down and with the backglass down it's like running the bikini top on our Jeep.-Power roll down rear window (like the quad cab tundras)

G100

Adventurer

Expedit-100n,

I like looks of your rig, especially with the black rims, what size tires are you running with and do you know backspacing on your rims? any rubbing?

Nice to know that I could fit two batteries up front like that, I was planning on putting my deep cycle in the bed like I did in my dakota (the silver box on the left side in the pic). It worked well as a night stand but would be nice to be able to use that space for something else.

I like looks of your rig, especially with the black rims, what size tires are you running with and do you know backspacing on your rims? any rubbing?

Nice to know that I could fit two batteries up front like that, I was planning on putting my deep cycle in the bed like I did in my dakota (the silver box on the left side in the pic). It worked well as a night stand but would be nice to be able to use that space for something else.

G100

Adventurer

Here is some electrical work that I felt I needed to get done before the rear window project.

I installed a little 6 way aux. fuse block next to original fuse block down by the clutch. I ran an 8 guage wire through some wire loom from the battery, through the driver side fender and popped it out right next to the existing fuse block. There was a perfect little spot to mount the block.

Then took apart my doors and ran 14 guage wire from the new fuse block to each of the door switches. I connected the wire so that I would have full-time power windows. I could have spiced the power from the door locks but I figure that the windows pull some amps so 14 guage should work nice, and if I blow a fuse my power locks will still work.

I couldn't get an attachment to connect my Ipod to the radio that came with the truck, so I sold it for $60 on ebay and found a really nice Alpine stereo for $67 shipped. Best $7 I have ever spent. Being able to run your stereo without the key in, is a must for me when I'm camping, so I wired a contura switch on the dash next to the radio that turns the stereo on and off. This was also wired up to the new fuse block.

I got this Ipod attachement which plugs into the cd changer port. Cool thing about this attachment is it plugs in to the bottom and can also charge your Ipod, plus it comes with 2 additional aux. ports, a headphone jack type and a RCA type. This way I can run an extension off one of these back to the bed of my truck, and have an additional port in the back.

While installing the radio I found a little metal box behind the panel below the ash tray, I believe the original radio attached to it and it ran the wires to the speakers. Well . . . no need for it any more so I pulled it out freeing up some room behind that panel. So I decided to install some full-time 12 volt power plugs, you can never have too many of those. Installation was pretty easy, just marked out where I wanted them and drilled some holes. This are nice cause they are low and out of the way of the shifter, unlike the factory one. These also are supplied power from the new fuse block.

Here is the pic of the new fuse block. Its hard to see but the 8 guage wire pops out of the wall just below the lower right corner of the new fuse block

Pic of the new radio and 12volt power outlets. The radio has a tilt feature that I am starting to like, it pops out a little so its easier to control with your hand resting on the shifter. You can see the switch that turns on the radio in the upper left and the Ipod cord in the lower right.

I installed a little 6 way aux. fuse block next to original fuse block down by the clutch. I ran an 8 guage wire through some wire loom from the battery, through the driver side fender and popped it out right next to the existing fuse block. There was a perfect little spot to mount the block.

Then took apart my doors and ran 14 guage wire from the new fuse block to each of the door switches. I connected the wire so that I would have full-time power windows. I could have spiced the power from the door locks but I figure that the windows pull some amps so 14 guage should work nice, and if I blow a fuse my power locks will still work.

I couldn't get an attachment to connect my Ipod to the radio that came with the truck, so I sold it for $60 on ebay and found a really nice Alpine stereo for $67 shipped. Best $7 I have ever spent. Being able to run your stereo without the key in, is a must for me when I'm camping, so I wired a contura switch on the dash next to the radio that turns the stereo on and off. This was also wired up to the new fuse block.

I got this Ipod attachement which plugs into the cd changer port. Cool thing about this attachment is it plugs in to the bottom and can also charge your Ipod, plus it comes with 2 additional aux. ports, a headphone jack type and a RCA type. This way I can run an extension off one of these back to the bed of my truck, and have an additional port in the back.

While installing the radio I found a little metal box behind the panel below the ash tray, I believe the original radio attached to it and it ran the wires to the speakers. Well . . . no need for it any more so I pulled it out freeing up some room behind that panel. So I decided to install some full-time 12 volt power plugs, you can never have too many of those. Installation was pretty easy, just marked out where I wanted them and drilled some holes. This are nice cause they are low and out of the way of the shifter, unlike the factory one. These also are supplied power from the new fuse block.

Here is the pic of the new fuse block. Its hard to see but the 8 guage wire pops out of the wall just below the lower right corner of the new fuse block

Pic of the new radio and 12volt power outlets. The radio has a tilt feature that I am starting to like, it pops out a little so its easier to control with your hand resting on the shifter. You can see the switch that turns on the radio in the upper left and the Ipod cord in the lower right.

RockyMtnFamily

Explorer

Expedit-100n,

I like looks of your rig, especially with the black rims, what size tires are you running with and do you know backspacing on your rims? any rubbing?

I am not sure of the backspacing as i bought the truck used. The tires are 31x11.50 Kumho Mud Terrains. When I purchased the truck the owner informed me that their son had bought this set of tires and rims and asked if I wanted the old set as well. I said yes, and out came a brand new set of Firestone tires with the little nubs still on them. Once I wear one of these sets out I will be upgrading to some 33x10.50 BFGs, but at the rate I am going that will be awhile.

I noticed we have the same stereo. I hope you like yours as much as I do mine. I look forward to seeing what you do with your truck.

Kevin

G100

Adventurer

The Window Build

Okay so heres the window build it was a pain in the as, but so worth it:

To start, the reason I came up with this idea, which was many many years before the tundras came out with it, was because I couldn't fit my longboard surfboards through my split window in my dakota. This was a big problem when I was traveling with my longboards because I couldn't lock them up. So I would be in some shaddy town, either in the U.S. or Mexico, and want to go out to eat or whatever and I would just have to hope that my boards will be there when I return. I tried riggin' up some surfboard locks and stuff, but nothing really worked or was too big of a pain. So thats the main reason but being able access and get back and forth between the front and back is just really nice especially when your sleeping in the bed of the truck.

I looked around on the internet for months to see if anyone has every done anything like this. The only thing I found was a low rider tacoma, heres the link, that used a 4 runner window regulator. Not too many pictures to help me out though.

So heres how the project started:

And the inside with the interior all ripped out.

Now here is my first design issue that almost made me give up on the project. There is a curve in the glass, so as you can see in the picture if the window was to go straight up it would be a couple inches away from where it needs to be.

So I thought about curved glass, but if the glass is curved, there isn't enough space behind the back-rest for when the window is down. I did not want to make the backseat more narrow. I had two inches behind the backseat back-rest to put the window and the lifting mechinism. So I figured for this to work the window would have to flex, it would need to be straight while in the down position and then flex as it rolls up. So I planned on using plexi-glass or poly-carbonate.

Well I never really was sure that this was going work at all, but I decided to just go for it, and figure it out along the way. So I made the first cut, and yes, the first cut is scary as $hit, but the rest just kept getting easier and easier.

Here I cut away the piece that back-rest bolts on to. The window will have to run behind this, so it will be eventually reinstalled. I used a combination of a jig-saw and a angle-grinder with a cut off wheel. At first I thought I could leave it attached at the sides but once the cuts were made it was too flimsy, I knew I needed to remove it completely and reinforce it.

So I then had to remove the rest by grinding off the spot welds.

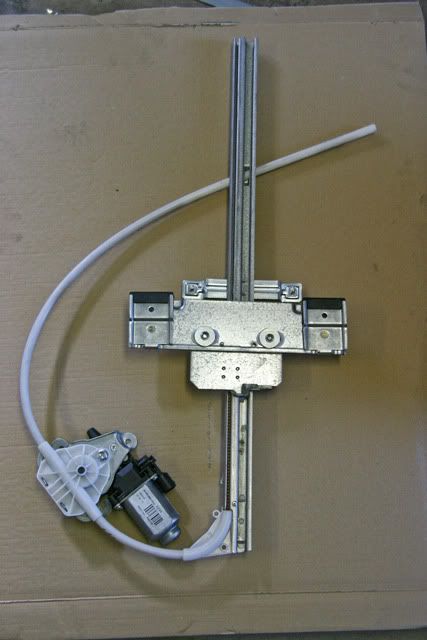

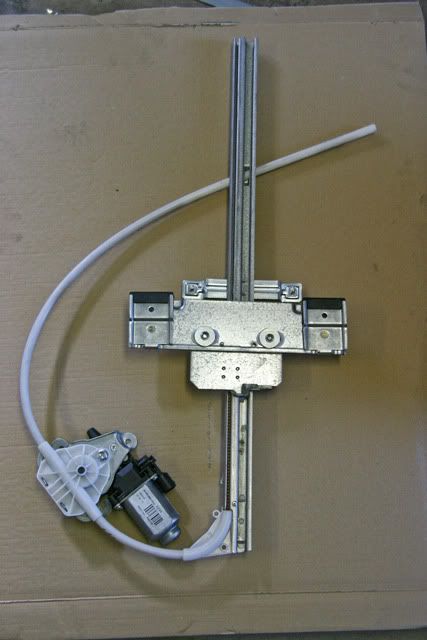

I decided to go with two window regulators rather then just one, I just felt I would have less problems with it rolling up. I decided on these universal regulators I found on the internet used for converting old classics cars to power windows. The company that makes them is Electric Life, and they are a little more then I wanted to spend but, they claimed that you could install them in a 2" wide space so thats why I got them, cause thats all the space I got.

Heres how them came out of the box.

The way that they came was obviously not going to work so I had to cut the motors off and then just try and rebuild them so they would fit. They are pretty simple, they just have a rigid coil in the white tube that that works like a gear and the motor just spins a spiral gear, works just like a crescent wrench, kinda.

I must admit I got pretty darn lucky, cause I found a way to fit these things in like they were ment to be there all along. The motors are not identical, they are mirror images of each other. I had to switch the motors and run the right motor fliped backwards and upside-down on the left side and vise-versa. Since I was running the motors fliped backward I had to re-engineer the mounts so they were backwards aswell.

Here is a shot of how I got the left side figured out. The right side is basically the mirror-image, but there is much less space on the right side then the left.

Now I had to deal with the next issue, these 3 little impressions that stick out about an inch futher then all the rest. They are used to support the back-rest and they are not going to work the way they are.

This is where the project became a big pain in the as.

Okay so heres the window build it was a pain in the as, but so worth it:

To start, the reason I came up with this idea, which was many many years before the tundras came out with it, was because I couldn't fit my longboard surfboards through my split window in my dakota. This was a big problem when I was traveling with my longboards because I couldn't lock them up. So I would be in some shaddy town, either in the U.S. or Mexico, and want to go out to eat or whatever and I would just have to hope that my boards will be there when I return. I tried riggin' up some surfboard locks and stuff, but nothing really worked or was too big of a pain. So thats the main reason but being able access and get back and forth between the front and back is just really nice especially when your sleeping in the bed of the truck.

I looked around on the internet for months to see if anyone has every done anything like this. The only thing I found was a low rider tacoma, heres the link, that used a 4 runner window regulator. Not too many pictures to help me out though.

So heres how the project started:

And the inside with the interior all ripped out.

Now here is my first design issue that almost made me give up on the project. There is a curve in the glass, so as you can see in the picture if the window was to go straight up it would be a couple inches away from where it needs to be.

So I thought about curved glass, but if the glass is curved, there isn't enough space behind the back-rest for when the window is down. I did not want to make the backseat more narrow. I had two inches behind the backseat back-rest to put the window and the lifting mechinism. So I figured for this to work the window would have to flex, it would need to be straight while in the down position and then flex as it rolls up. So I planned on using plexi-glass or poly-carbonate.

Well I never really was sure that this was going work at all, but I decided to just go for it, and figure it out along the way. So I made the first cut, and yes, the first cut is scary as $hit, but the rest just kept getting easier and easier.

Here I cut away the piece that back-rest bolts on to. The window will have to run behind this, so it will be eventually reinstalled. I used a combination of a jig-saw and a angle-grinder with a cut off wheel. At first I thought I could leave it attached at the sides but once the cuts were made it was too flimsy, I knew I needed to remove it completely and reinforce it.

So I then had to remove the rest by grinding off the spot welds.

I decided to go with two window regulators rather then just one, I just felt I would have less problems with it rolling up. I decided on these universal regulators I found on the internet used for converting old classics cars to power windows. The company that makes them is Electric Life, and they are a little more then I wanted to spend but, they claimed that you could install them in a 2" wide space so thats why I got them, cause thats all the space I got.

Heres how them came out of the box.

The way that they came was obviously not going to work so I had to cut the motors off and then just try and rebuild them so they would fit. They are pretty simple, they just have a rigid coil in the white tube that that works like a gear and the motor just spins a spiral gear, works just like a crescent wrench, kinda.

I must admit I got pretty darn lucky, cause I found a way to fit these things in like they were ment to be there all along. The motors are not identical, they are mirror images of each other. I had to switch the motors and run the right motor fliped backwards and upside-down on the left side and vise-versa. Since I was running the motors fliped backward I had to re-engineer the mounts so they were backwards aswell.

Here is a shot of how I got the left side figured out. The right side is basically the mirror-image, but there is much less space on the right side then the left.

Now I had to deal with the next issue, these 3 little impressions that stick out about an inch futher then all the rest. They are used to support the back-rest and they are not going to work the way they are.

This is where the project became a big pain in the as.

G100

Adventurer

So I had to get some friends of mine over to help me take the bed off before I could start doing anything. You can see the three deep dimples that have have to be cut out.

Then I welded these nuts to some washers and the washers to the truck so that when the bed does go back on, I will be able get the bolts in and out with no hassel. This is for the bolts that hold the motor brackets and the lifting tracks.

Now, I have never done any major body work before so this part was a little scary, but it had to be done. Three big holes cut out.

I made three of these filler plates to fill the holes. Pretty easy just bent them in a vise, I believe they are made out of 16 guage.

Here I am welding the filler plates into place. It was pretty tough, I learned a lot. The first one went pretty smooth, I got lucky, the second one went horrible, holes and more holes, and I learned enough from the mistakes I made on the second one that the third plate went in alright. The key is to make the filler plate atleast 1/8 inch bigger on all sides.

I grinded it down, covered it with bondo, sanded it smooth, and painted it up. The whole process from cutting to painting took me about three days. My neighbors were not happy to say the least with all the noise I was making while grinding, we had some words. As for painting, for the inside I just put on an etching primer and for the outside I did the same primer and then spayed on some PlasticKote spraypaint, it looks like a pretty tough paint.

The hardest part is over!

Then I welded these nuts to some washers and the washers to the truck so that when the bed does go back on, I will be able get the bolts in and out with no hassel. This is for the bolts that hold the motor brackets and the lifting tracks.

Now, I have never done any major body work before so this part was a little scary, but it had to be done. Three big holes cut out.

I made three of these filler plates to fill the holes. Pretty easy just bent them in a vise, I believe they are made out of 16 guage.

Here I am welding the filler plates into place. It was pretty tough, I learned a lot. The first one went pretty smooth, I got lucky, the second one went horrible, holes and more holes, and I learned enough from the mistakes I made on the second one that the third plate went in alright. The key is to make the filler plate atleast 1/8 inch bigger on all sides.

I grinded it down, covered it with bondo, sanded it smooth, and painted it up. The whole process from cutting to painting took me about three days. My neighbors were not happy to say the least with all the noise I was making while grinding, we had some words. As for painting, for the inside I just put on an etching primer and for the outside I did the same primer and then spayed on some PlasticKote spraypaint, it looks like a pretty tough paint.

The hardest part is over!

G100

Adventurer

So this is how I did my tracks, it took a little while to figure out how I was going to do this. The tricky part being how to be able to install and remove the window. I came up tracks that are divided into two sections, the lower straight part and a the upper curved part which will be removable. This way I can install the window with just the lower part of the tracks in, slide it all the way down, then install the two upper curved track portions. The glass run channel, that is made out of felt, will not be two parts it will be held out of the way while sliding the window down then pushed into place in the curved track once it is installed all while the window is in the down position.

I hope thats not too wordy here are some pictures.

I couldn't find c-channel that was the size I needed so I made the lower tracks out 3/4 in. tubular steel, the inner dimension is 1/2 in. which is what I was after. I cut out one side enough to get a slim grinding wheel in there to smooth it out to the edge.

I had to also make a cuppler piece that will hold and align the upper and lower parts of the track together. It will be welded to the lower part and the upper curved part will just slide in to position. I also have to weld on some tabs for mounting the trackto the back wall.

The upper part of the track is made out of aluminium, it is actually just 1/2" plywood edging, you can find it at most hardware stores. It took a while to get the curve perfect, but it fits. I am using the existing window frame which is going to make things a lot easier. I had remove a center wall in the top part of the frame, making the two small channels that the old slider used, into one big channel aprox. 3/4" wide. The top of the curved track piece fits right inside that window frame channel. So that the track (and window) doesn't have to curve as much it goes more straight and sits on inward side of frame, where it slides into the cuppler piece attached to the lower part of the track.

I got my felt glass run channels from C R Laurence I also got 2 types of weather striping that the plexi-glass will rub along when rolling up or down. I got this kind and this kind.

I then used some cardboard to make some templates for the wing pieces. These wing peices will be welded to the frame, then the curved piece will have some little screws through the back of the channel, fastening it to the wing.

Here is how it will look. Of course it will be painted black.

I don't have a welder capable of welding aluminium so I had someone weld it up for me.

This is the "beaded weather striping" I got. The glass with be rubbing on this especially if someone is sitting in the back seat leaning against the back rest. I glued it on with some J&B Weld.

Here is all the parts I fab-ed up painted black. I used a black epoxy primer, I love the flat black look. You will also notice my lifter bar, very simple, just some c-channel with the tabs welded on that bolt onto the lifting regulators.

Here is what is looks like put together, and thats a piece of polycarbonate for the window. Very happy with how it all turned out. I had some issues with the motors running at different speeds, but I get into that later.

I hope thats not too wordy here are some pictures.

I couldn't find c-channel that was the size I needed so I made the lower tracks out 3/4 in. tubular steel, the inner dimension is 1/2 in. which is what I was after. I cut out one side enough to get a slim grinding wheel in there to smooth it out to the edge.

I had to also make a cuppler piece that will hold and align the upper and lower parts of the track together. It will be welded to the lower part and the upper curved part will just slide in to position. I also have to weld on some tabs for mounting the trackto the back wall.

The upper part of the track is made out of aluminium, it is actually just 1/2" plywood edging, you can find it at most hardware stores. It took a while to get the curve perfect, but it fits. I am using the existing window frame which is going to make things a lot easier. I had remove a center wall in the top part of the frame, making the two small channels that the old slider used, into one big channel aprox. 3/4" wide. The top of the curved track piece fits right inside that window frame channel. So that the track (and window) doesn't have to curve as much it goes more straight and sits on inward side of frame, where it slides into the cuppler piece attached to the lower part of the track.

I got my felt glass run channels from C R Laurence I also got 2 types of weather striping that the plexi-glass will rub along when rolling up or down. I got this kind and this kind.

I then used some cardboard to make some templates for the wing pieces. These wing peices will be welded to the frame, then the curved piece will have some little screws through the back of the channel, fastening it to the wing.

Here is how it will look. Of course it will be painted black.

I don't have a welder capable of welding aluminium so I had someone weld it up for me.

This is the "beaded weather striping" I got. The glass with be rubbing on this especially if someone is sitting in the back seat leaning against the back rest. I glued it on with some J&B Weld.

Here is all the parts I fab-ed up painted black. I used a black epoxy primer, I love the flat black look. You will also notice my lifter bar, very simple, just some c-channel with the tabs welded on that bolt onto the lifting regulators.

Here is what is looks like put together, and thats a piece of polycarbonate for the window. Very happy with how it all turned out. I had some issues with the motors running at different speeds, but I get into that later.

Poorboyota26

Adventurer

WOW!!!!!!! great work and great Ideas!!! I'm inspired! :wings::drool:

G100

Adventurer

Heres a couple shots from the back:

You can see I took off my third brake light and made a flat plate to cover it. I painted it with that same Plastic-Kote paint and then sealed the gap with some 3M weather seal stuff. Once my camper shell is installed the light would interfere with boot that I am going to have to install between the truck and shell.

I took some of the noise padding that was factory installed behind back-rest, cut it up and used some double stick tape to install it in the recessions.

Now here is my electrical situation and setup:

Ever since I got my motors installed when I would run them I noticed that one motor would reach the top a lot faster. I made sure my wires were exactly the same length, size and everything. I called the company that makes them and they were no help. I messed around with all different possiblilites and solutions, like using resistors, but had to eventually end up solving the problem by running the power to the faster motor through almost an entire 50ft spool of 12 guage wire. I just kept cutting little pieces off, fine tuning it until the resistance of the length of wire slowed the faster motor down to the speed of the other motor. I know its getto but this is the only way I could solve the problem.

I am using a reverse polarity relay setup used for power door locks that I got off of the12volt.com a very helpfull web site.

So since I had to store a 50ft spool of wire somewhere, I put together a little black box that housed my relays and the 50 ft of wire all coiled up. I drilled some holes and installed some disconnects for each wire that has to attach.

This relay setup is really nice because I don't have to run a wire to the switches, only two ground wires from a switch to the black box, this cuts out a lot of wiring because I am going to have multiple switches. Each momentary-off-momentary switch is connected to a ground and the two wires that go to the black box. So when I push a button, it grounds one wire going to the black box, which triggers one of the relays, which gives the motors power in one direction.

You can see I took off my third brake light and made a flat plate to cover it. I painted it with that same Plastic-Kote paint and then sealed the gap with some 3M weather seal stuff. Once my camper shell is installed the light would interfere with boot that I am going to have to install between the truck and shell.

I took some of the noise padding that was factory installed behind back-rest, cut it up and used some double stick tape to install it in the recessions.

Now here is my electrical situation and setup:

Ever since I got my motors installed when I would run them I noticed that one motor would reach the top a lot faster. I made sure my wires were exactly the same length, size and everything. I called the company that makes them and they were no help. I messed around with all different possiblilites and solutions, like using resistors, but had to eventually end up solving the problem by running the power to the faster motor through almost an entire 50ft spool of 12 guage wire. I just kept cutting little pieces off, fine tuning it until the resistance of the length of wire slowed the faster motor down to the speed of the other motor. I know its getto but this is the only way I could solve the problem.

I am using a reverse polarity relay setup used for power door locks that I got off of the12volt.com a very helpfull web site.

So since I had to store a 50ft spool of wire somewhere, I put together a little black box that housed my relays and the 50 ft of wire all coiled up. I drilled some holes and installed some disconnects for each wire that has to attach.

This relay setup is really nice because I don't have to run a wire to the switches, only two ground wires from a switch to the black box, this cuts out a lot of wiring because I am going to have multiple switches. Each momentary-off-momentary switch is connected to a ground and the two wires that go to the black box. So when I push a button, it grounds one wire going to the black box, which triggers one of the relays, which gives the motors power in one direction.

G100

Adventurer

Now all thats left to do is work on that cross member piece that holds the back-rest on and figure out the weather-striping.

The cross member piece definately needs some reinforcement especially because it will be leaned up against. I am going to put on some of that felt "beaded weather striping" from CRLaurence to pad it against the window.

I shaped a piece of 3/4 in" square tubing to fit and welded it on.

Figuring out the weather striping was a little difficult, I ended up cutting a little out of the center of the bigger weather-stripping so I could glue on the smaller one that the window will be running against.

Then I welded a 1.5" strip along the top of the cross member to glue the stripping on. You can also see the two holes on the edge that slip over the bolts welded on the lower tracks. The holes that run along center are for the piece of plastic that covers all of this.

Then I ran into a problem, when I put it all together the force that the cross-member and weather-stripping puts on the window outward makes the window not sit correctly into the top channel. About 8 inches in the center bows out, I figure this is because the there is nothing really pulling it in to create the curve it needs to sit correctly. The sides sit fine because the tracks bend the glass, but thats not enough to bend the middle. So for now I just have to help it by pushing in from the outside when it gets to the top, a real PITA. So I am going to try and put a small bend in the top with a heat gun.

I was originally going to use the polycarbonate, because of its strength, and tint it, but I was told that the tinting would not last more then a month or so without getting bubbles because the plastic slowly gives off gases. So I went to the plastic store was told that I should be using plexi-glass for a number of reasons. It is more ridgid so it will hold a bend better, it is more scratch resitant, I can get it in a smoked (tinted) look, and it is almost half the price. Real glad that I spent the $80 on that piece of polycarbonate

So I got the 3/8" smoked plexi-glass. I made a bending jig with a bend more then what I want, covered it with a fleece blanket so not to scratch it. Clamped it down and ran a heat gun over it.

This worked perfectly. . . for about two days. The glass started to lose its bend. I think maybe because when it is in the down position it is being flexed back straight.

So now I am ready for my camper shell ! ! ! I can't wait.

Anyway here are some photos of the "Finished For Now" Window Project:

The cross member piece definately needs some reinforcement especially because it will be leaned up against. I am going to put on some of that felt "beaded weather striping" from CRLaurence to pad it against the window.

I shaped a piece of 3/4 in" square tubing to fit and welded it on.

Figuring out the weather striping was a little difficult, I ended up cutting a little out of the center of the bigger weather-stripping so I could glue on the smaller one that the window will be running against.

Then I welded a 1.5" strip along the top of the cross member to glue the stripping on. You can also see the two holes on the edge that slip over the bolts welded on the lower tracks. The holes that run along center are for the piece of plastic that covers all of this.

Then I ran into a problem, when I put it all together the force that the cross-member and weather-stripping puts on the window outward makes the window not sit correctly into the top channel. About 8 inches in the center bows out, I figure this is because the there is nothing really pulling it in to create the curve it needs to sit correctly. The sides sit fine because the tracks bend the glass, but thats not enough to bend the middle. So for now I just have to help it by pushing in from the outside when it gets to the top, a real PITA. So I am going to try and put a small bend in the top with a heat gun.

I was originally going to use the polycarbonate, because of its strength, and tint it, but I was told that the tinting would not last more then a month or so without getting bubbles because the plastic slowly gives off gases. So I went to the plastic store was told that I should be using plexi-glass for a number of reasons. It is more ridgid so it will hold a bend better, it is more scratch resitant, I can get it in a smoked (tinted) look, and it is almost half the price. Real glad that I spent the $80 on that piece of polycarbonate

So I got the 3/8" smoked plexi-glass. I made a bending jig with a bend more then what I want, covered it with a fleece blanket so not to scratch it. Clamped it down and ran a heat gun over it.

This worked perfectly. . . for about two days. The glass started to lose its bend. I think maybe because when it is in the down position it is being flexed back straight.

So now I am ready for my camper shell ! ! ! I can't wait.

Anyway here are some photos of the "Finished For Now" Window Project:

Similar threads

- Replies

- 3

- Views

- 790

- Replies

- 34

- Views

- 801

- Replies

- 3

- Views

- 1K

- Replies

- 12

- Views

- 1K

- Replies

- 8

- Views

- 497