Betonhaus

New member

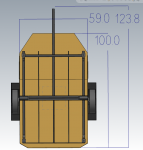

Hi I wanted to get a sanity check and part sourcing recommendations for a trailer I'm planning to build to tow behind my Fiesta. All I want is something that has hard walls so I can jump in and get comfortable even when it's wet or chilly outside instead of tenting. So far the concept I've come up with is shown below, based on my math it should weigh about 375-400lbs and cost about $3,000(CAD) for parts (before shipping, and I think i can shop around for some parts or get them on sale). It's big enough to fit a full/double sized mattress (to ensure it is narrower then the car and reduce wind resistance and lets me see behind me without using mirror extensions) with room in the front for luggage or whatev, shaped to improve aerodynamics.

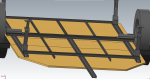

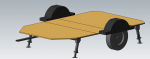

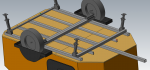

The basic design relies on torsion half-axles (weight, independent so more stable) bolted to a welded steel frame consisting of two 2x1x.12" tubes (tubes to ensure the axles are secure but I think i can just weld a plate to bolt the axles onto so I can coat the entire frame with protective paint easily) with 80x2x1x.125" channel for the main support resting on top with some bracing, all screwed onto 1/2"mdf plywood (heard you the first three times) flooring for additional structural stability, the walls are made of 1.5" ridged foam insulation coated in a poor-man's fibreglass (cotton canvas and truck bed liner) for added rigidity and protection (possibly improved aerodynamics if the rough surface causes the golf ball effect in any meaningful way), then with two 26x36" door kits (found here= Doors (teardroptrailerparts.com) ) they also act as ventilation but I'll likely stick a crank style dome vent on top as a third ventilation source.

Based on all the time I've been working on this, this should be the lightest I can make it without going into extremely expensive materials. If I only load camping gear into it it shouldn't have more then maybe 600lbs resting on the frame, and if I always use the jacks when parked the weight of anyone inside it will be distributed on six points, should be more then enough for the frame to handle.

I guess my main questions are:

1. Is my logic sound? will the trailer be able to handle it's load with these parts? is it okay welding the frame together like this?

2. Is there an alternative source for the doors I could use? After searching and searching I've concluded that a prebuilt door is the best and this site is the only place that offers these doors, but they account for basically half of the entire cost of the trailer.

The basic design relies on torsion half-axles (weight, independent so more stable) bolted to a welded steel frame consisting of two 2x1x.12" tubes (tubes to ensure the axles are secure but I think i can just weld a plate to bolt the axles onto so I can coat the entire frame with protective paint easily) with 80x2x1x.125" channel for the main support resting on top with some bracing, all screwed onto 1/2"

Based on all the time I've been working on this, this should be the lightest I can make it without going into extremely expensive materials. If I only load camping gear into it it shouldn't have more then maybe 600lbs resting on the frame, and if I always use the jacks when parked the weight of anyone inside it will be distributed on six points, should be more then enough for the frame to handle.

I guess my main questions are:

1. Is my logic sound? will the trailer be able to handle it's load with these parts? is it okay welding the frame together like this?

2. Is there an alternative source for the doors I could use? After searching and searching I've concluded that a prebuilt door is the best and this site is the only place that offers these doors, but they account for basically half of the entire cost of the trailer.

Last edited: