Some more notes from my D18/20 building....

A magnetic base and dial indicator is nice to have around. Make sure to mark the position you use on the end of the shaft. My shaft had about .010 runout on the end of the threaded portion. You can also use the shoulder just up the shaft from the threads where it tapers into the splines. This was about .002 runout but if much harder to get a tip on the flat section.

After some trial and error with the shim stack, I got it as close as possible. I ended up with a lot of thin shims. Novak only includes thin shims in there kit. The t-case I used for parts had thin shims. I couldn't find the shims from the D20 tear down.

After a few tries I finally got down into the .002 range with all the gaskets dry.

My basic therory was that I roughly set the rear bearing cone till I only had about .030 of movement in the shaft. Then I measured the pocket on the rear housing ( about .099 to .105 ) and the amount that the cone was sticking out of the case ( about .190 or so ). From this I knew I needed about .090-.100 in shim for the .030 in shaft movement. I had a goal of .005 shaft play so I build a shim pack to get around .075" thick. This was a good starting point and was only need one or two adjustments to get down to the .002-.003 range.

Shims are not THAT consistent when measuring. I cleaned and cleaned them but always had about .002 difference between the individual shims if they are all suppose to be .010 or whatever.

The final (dry) was .002 as far a I could tell. I had to tap the end of the shaft forward with a hammer and then pry it back to get that movement. This is a little tight, but i figured that things would open up with sealant on the front housing gasket and copper on the shims.

The front housing was pulled and high-tack used on both metal surfaces and the .030 thick gasket. I tried to torque all the front output bolts the same but some of the bolts are pretty shrouded so it wasn't as simple as getting a torque wrench and socket on them.

All the bolts in the front cover where also thread sealed.

I sprayed all the shims with copper spray and let sit for 1-2 minutes until tacky. Then I assembled then all into a stack and sprayed the back side of the last shim. I hope this will give enough coverage on all the shims without going overkill.

Then I assembled everything, thread sealed, and torqued the rear housing bolts.

All in all it turned out pretty good. Maybe a little tight at .003+ish. It kinda depends on how much leverage I use to move the shaft. It feels butter smooth and doesn't have any notchy feeling or binding to it. I am pretty happy with out it turned out.

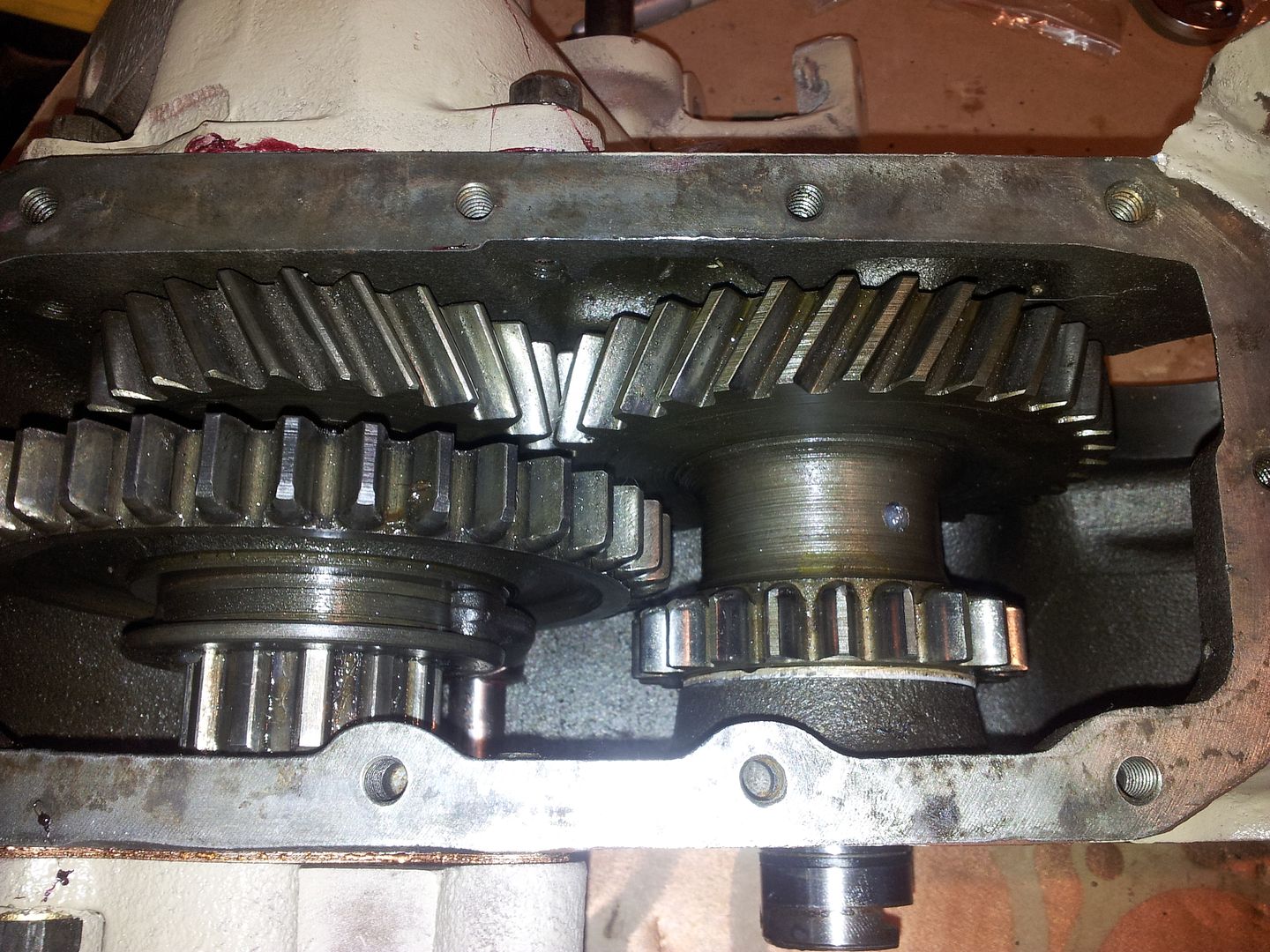

Next I set up the intermediate gear bearings. I don't know what the big deal is. A little petroleum jelly that sat in the freezer and everything held its place great. Lots of bearings. Don't forget the 3 spacer washers either. One on each end and one in the middle of the two sets of bearings.

Some more frozen jelly worked good to hold the thrust washers in place. All in all the OEM shaft went in just fine.....

One hint. Stop for a second installing the shaft at this point just when you get the shaft past the forward thrust washer...

Clean out the extra jelly here after installing the shaft. Then use a finger smear of right stuff before tapping the shaft into its final home. The oem shaft is a TIGHT fit for the last 1/2" or so!

Then install the keeper with a little locktite and/or sealant. This hole is blind I am pretty sure so it shouldn't matter. But I have been trying to seal everything as much as I can.

It also seem to help if you lock the sliding low range gear into neutral during the install so your not trying to mesh two gears at once. Only install the ball and spring AFTER your done installing the sealant on the front housing gasket.

I also found it help full to install the ball and spring for the 4wd shift detents when I built the front housing to keep everything in the '4wd' position when playing with the front housing.

Novak includes a super thick bottom cover gasket! Its a rubber composite gasket I think....

That is as far as I got tonight.....

All in all it only took most of my lunch half hour including trying a few other things that didn't work.

All in all it only took most of my lunch half hour including trying a few other things that didn't work.