You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rango.....1942 Willys MB

- Thread starter Metcalf

- Start date

Metcalf

Expedition Leader

Today was spacer fabrication day.......

Helpful shop tip of the day. When your trying to test fit a spacer in a space where you have limited access....use tape!

This makes it easy to pull out the spacer after the test fit. This only works with slip fit parts but it is still WAY handy!

I made this spacer to replace the speedometer drive gear. I don't run a speedometer so I don't have to worry about it. But WHY make a new spacer?

Here is your standard front style regular 10-spline yoke installed on the rear. You can see how close the yoke is to the end of the rear output housing. You CANNOT run a regular front yoke on the rear without a longer spacer. You will NOT be able to properly torque the rear output without the yoke or dust shield binding on the housing.

Why run a front yoke in the rear? It buys you +1" of rear driveline length at least. In a flat fender every inch counts.

I made the new spacer approx .160-.170" longer than the stock part. This JUST gives me enough room on the rear output yoke for proper torque on the rear output yoke castle nut. You need some space between the yoke and end of shaft, it can't be perfectly flush or things will wobble. My new spacer was a 1.188 ID, whatever od fit, and 1.170" long.

Option two would be to trim back the rear output housing. There is a little bit of room to do this and you could get a slightly shorter setup. At some point however the end of the output shaft will hit the u-joint however.

While I worked on the 1st spacer I cut some material for the 2nd. I had bored a hole on the big lathe at work during lunch in this part. This took a while to cut! I am sure happy I have a saw I can walk away from and do other things. Again, best $225 I probably spent in the shop.

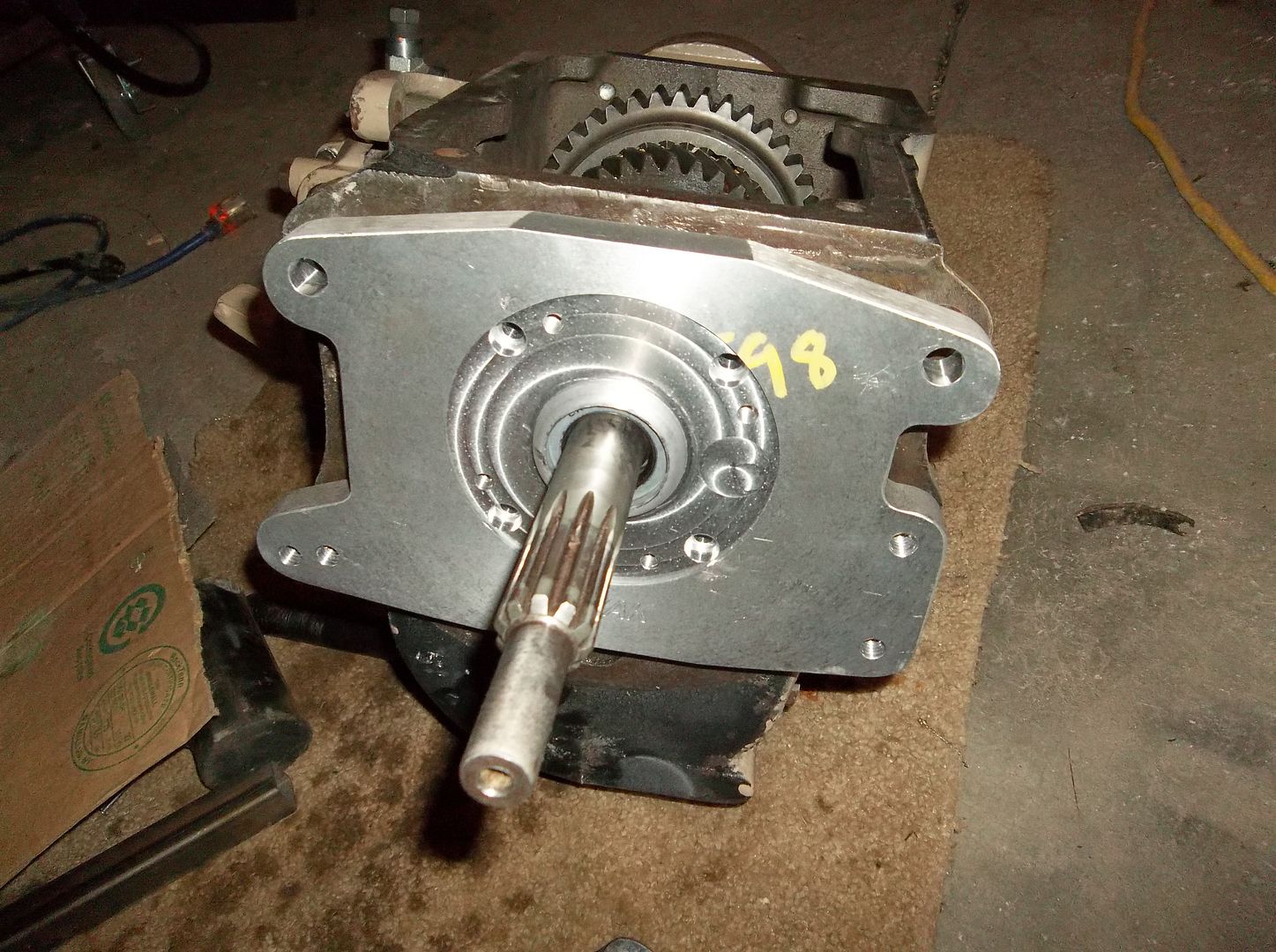

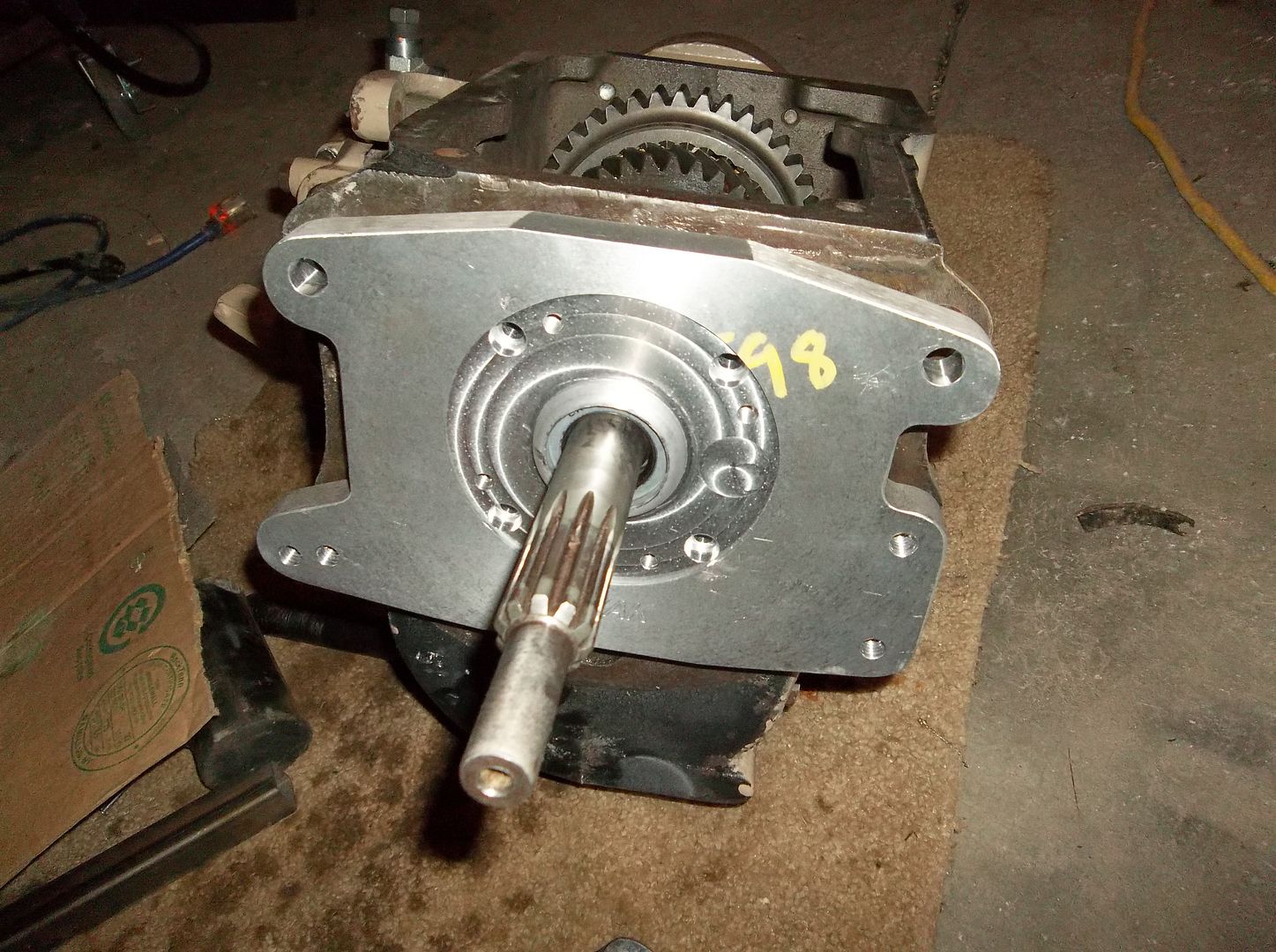

Here is what I made out of that big chunk of material. It is a new spacer that goes between the transmission output shaft bearing and the Dana 18 input gear. My transmission didn't come with one so I had to reverse engineer one. I used the same seal as AA does in there adapter. I posted a pic and part number yesterday, but the AA part is listed as a National #473468. It has a 2.125" ID. I made this new spacer with as smooth a surface as possible without going under that dimension. Mine ended up at about 2.125-2.130. I used lots of sand paper to try and get it as smooth as possible. It worked ok. Grinding it or finding some pre-made shaft material would have been better.

The spacer goes down in here. Make sure to lube it to protect the seal. Don't forget to put a little RTV or something on the inside to stop that leak path.

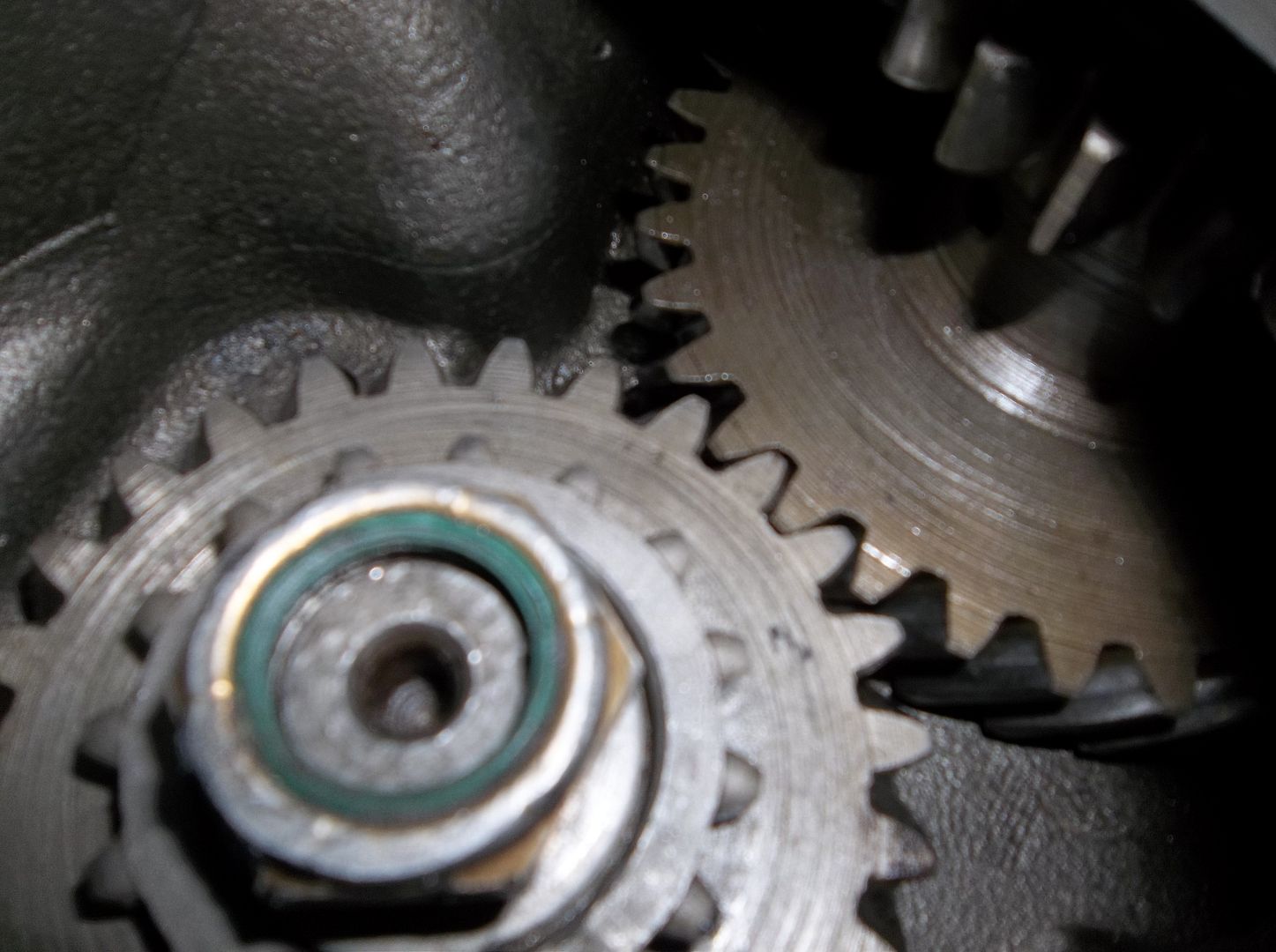

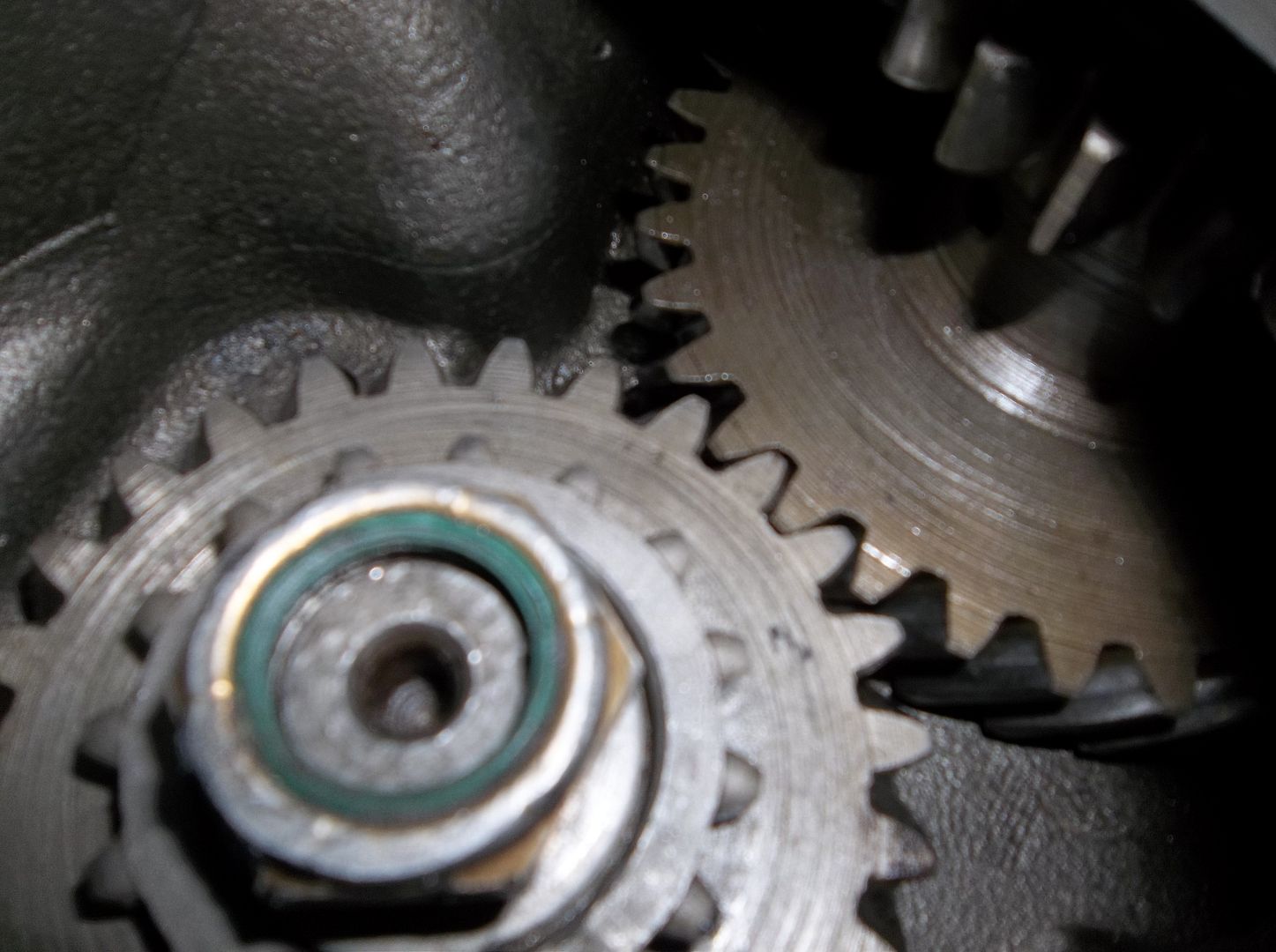

Here is the input gear installed on the spacer. I think I got the position just about as good as possible. There is VERY little difference in gear height. I can't measure it, and there is MAYBE something to feel but I would guess that it is less than 0.010, maybe 0.005".

I made my spacer to be 1.475" long. That is the number I came up with my measuring the depth from the face of the intermediate gear to the transmission output shaft bearing. I took that measurement and subtracted the height in the Dana 18 input gear.

I few people sent me some stock spacer measurements...

jalbrecht42's T98 was 1.438" long

Joe Martin has a T18 in the garage. His was 1.434" long

I do have a gasket between the transfer case adapter and transmission and that could have added some length. I need to grab a piece of the material and measure it.

The gear matches up as perfect as you could want though, so I think the length I used is serviceable.

Helpful shop tip of the day. When your trying to test fit a spacer in a space where you have limited access....use tape!

This makes it easy to pull out the spacer after the test fit. This only works with slip fit parts but it is still WAY handy!

I made this spacer to replace the speedometer drive gear. I don't run a speedometer so I don't have to worry about it. But WHY make a new spacer?

Here is your standard front style regular 10-spline yoke installed on the rear. You can see how close the yoke is to the end of the rear output housing. You CANNOT run a regular front yoke on the rear without a longer spacer. You will NOT be able to properly torque the rear output without the yoke or dust shield binding on the housing.

Why run a front yoke in the rear? It buys you +1" of rear driveline length at least. In a flat fender every inch counts.

I made the new spacer approx .160-.170" longer than the stock part. This JUST gives me enough room on the rear output yoke for proper torque on the rear output yoke castle nut. You need some space between the yoke and end of shaft, it can't be perfectly flush or things will wobble. My new spacer was a 1.188 ID, whatever od fit, and 1.170" long.

Option two would be to trim back the rear output housing. There is a little bit of room to do this and you could get a slightly shorter setup. At some point however the end of the output shaft will hit the u-joint however.

While I worked on the 1st spacer I cut some material for the 2nd. I had bored a hole on the big lathe at work during lunch in this part. This took a while to cut! I am sure happy I have a saw I can walk away from and do other things. Again, best $225 I probably spent in the shop.

Here is what I made out of that big chunk of material. It is a new spacer that goes between the transmission output shaft bearing and the Dana 18 input gear. My transmission didn't come with one so I had to reverse engineer one. I used the same seal as AA does in there adapter. I posted a pic and part number yesterday, but the AA part is listed as a National #473468. It has a 2.125" ID. I made this new spacer with as smooth a surface as possible without going under that dimension. Mine ended up at about 2.125-2.130. I used lots of sand paper to try and get it as smooth as possible. It worked ok. Grinding it or finding some pre-made shaft material would have been better.

The spacer goes down in here. Make sure to lube it to protect the seal. Don't forget to put a little RTV or something on the inside to stop that leak path.

Here is the input gear installed on the spacer. I think I got the position just about as good as possible. There is VERY little difference in gear height. I can't measure it, and there is MAYBE something to feel but I would guess that it is less than 0.010, maybe 0.005".

I made my spacer to be 1.475" long. That is the number I came up with my measuring the depth from the face of the intermediate gear to the transmission output shaft bearing. I took that measurement and subtracted the height in the Dana 18 input gear.

I few people sent me some stock spacer measurements...

jalbrecht42's T98 was 1.438" long

Joe Martin has a T18 in the garage. His was 1.434" long

I do have a gasket between the transfer case adapter and transmission and that could have added some length. I need to grab a piece of the material and measure it.

The gear matches up as perfect as you could want though, so I think the length I used is serviceable.

Metcalf

Expedition Leader

Some new bling.....

My Novak adapter arrived. It looks like it will work great. It is a very nice quality piece.

I did run into a snag with the clutch disc. The Novak 11" disc will not work on a Buick 225 flywheel. What I need is a 10.5" dia, 10-spline, 1.060 clutch disc. Anyone have any application ideas? I am going to go look around on rockauto.

My Novak adapter arrived. It looks like it will work great. It is a very nice quality piece.

I did run into a snag with the clutch disc. The Novak 11" disc will not work on a Buick 225 flywheel. What I need is a 10.5" dia, 10-spline, 1.060 clutch disc. Anyone have any application ideas? I am going to go look around on rockauto.

A lot of Fords used 10 spline 1 1/16" (1.0625") clutches. Mostly 10" or 11", but Centerforce is showing this 10.4" disc: https://www.centerforce.com/product...-01-ford-merc-flathead-mustang-mustang-ii-mus

Metcalf

Expedition Leader

Just a little bit....

I was able to file out the upper two mounting ears on the T18 to mate up to the Novak adapter ( and the top two holes of the GM transmission pattern ). All the other stuff is bolt up at this point, I just need to sort out all the hardware.

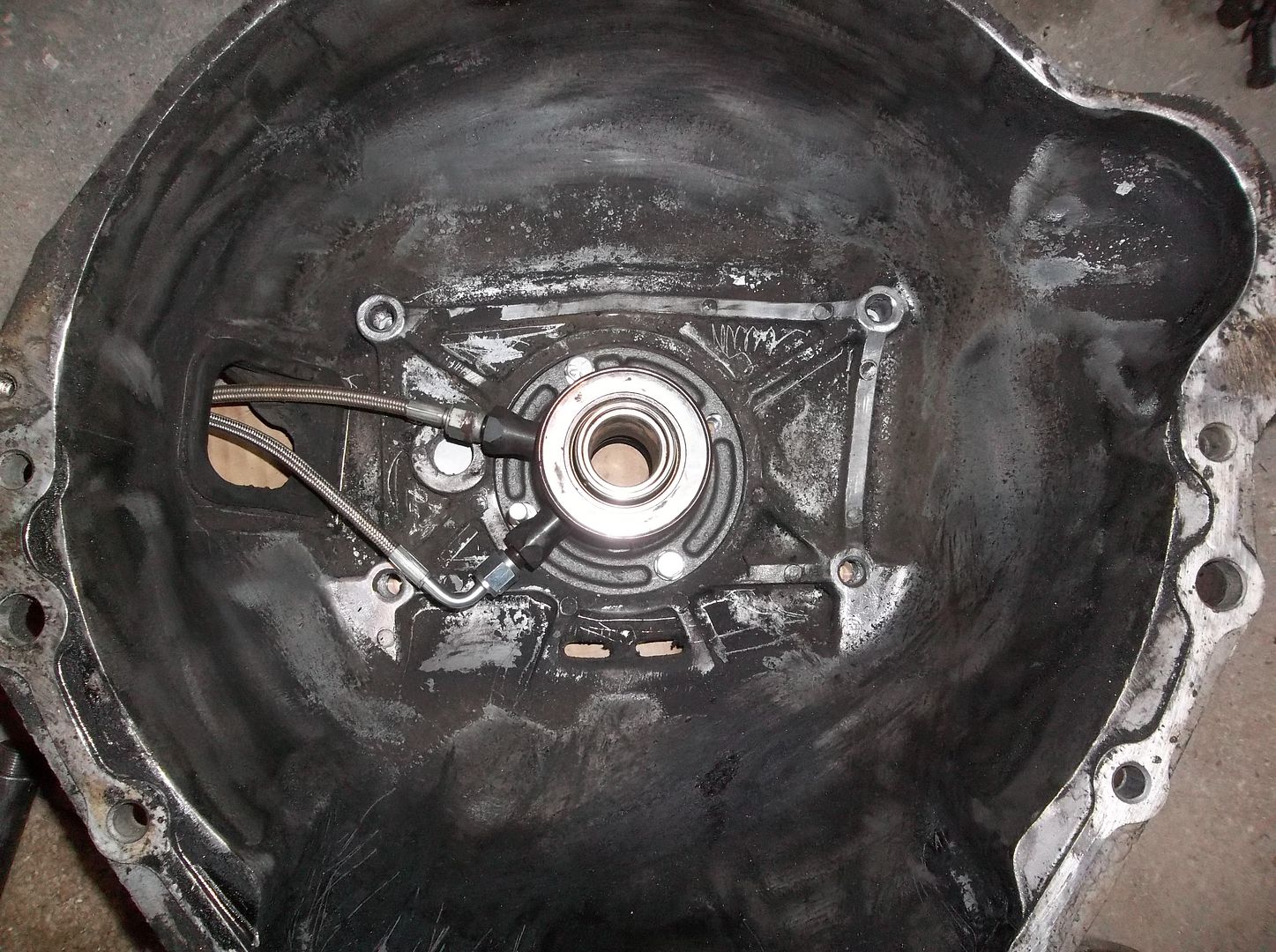

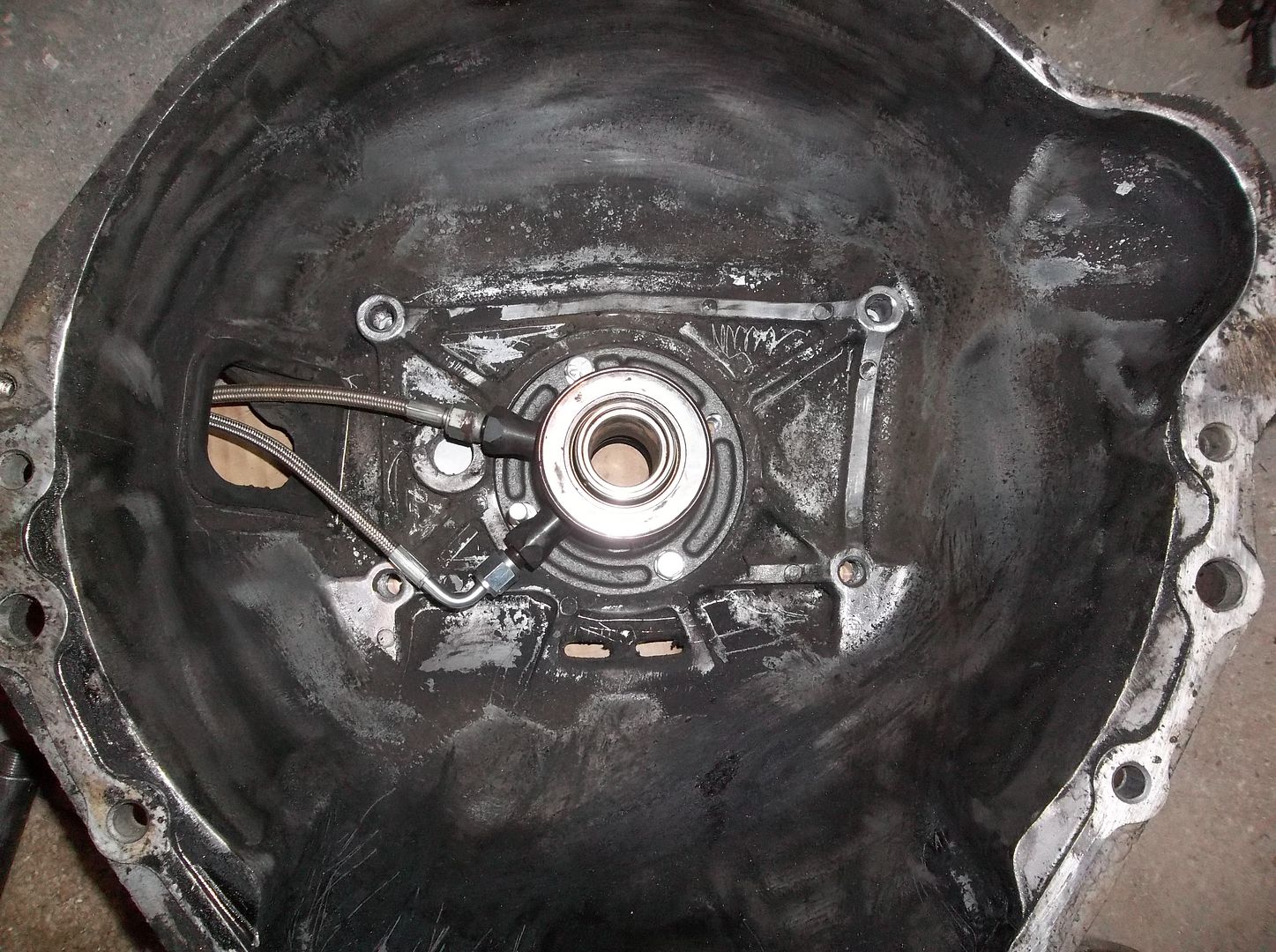

I was also able to pull the spare engine out from under the table and pull the stock unmolested bellhousing off the back. This is the bellhousing I will be using on the conversion...after it gets a bath. The bellhousing I used with the SM420 had a few holes modified to use with that transmission.

I can button up the install of the adapter on the transmission but I am basically waiting for my clutch disc to come in at this point...

I was able to file out the upper two mounting ears on the T18 to mate up to the Novak adapter ( and the top two holes of the GM transmission pattern ). All the other stuff is bolt up at this point, I just need to sort out all the hardware.

I was also able to pull the spare engine out from under the table and pull the stock unmolested bellhousing off the back. This is the bellhousing I will be using on the conversion...after it gets a bath. The bellhousing I used with the SM420 had a few holes modified to use with that transmission.

I can button up the install of the adapter on the transmission but I am basically waiting for my clutch disc to come in at this point...

Metcalf

Expedition Leader

I finally got my clutch disc!

This seems to be the proper unit for my application ( Buick 225 odd fire V6 ). It is the same size as what was in the vehicle before with the SM420 transmission BUT has a 1.060" 10 spline hub. This clutch is from a 1979 CJ5/7 with the I6 engine. I think this would have been the factory application for my T18 transmission.

I didn't have a clutch alignment tool, so I turned one down on the lathe out of some scrap bar stock. Yet another reason to have a lathe in your shop. I am on the fence with what would be more useful....mill or lathe. I know I will have a HARD time if I can't have a lathe anymore.

This was my big issue for the night. I transfered over my existing hydraulic throw-out bearing to the new transmission configuration.

http://www.speedwaymotors.com/GM-Stock-Clutch-Hydraulic-Throwout-Bearing,1945.html

I really wanted to add a remote bleed line to make life easier. I bought a straight 12" an-4 line to make into a bleed line but with the way the bearing retainer is orientated on the bellhousing adapter you really need a 90 degree fitting to get it going the right way. Luckly I had ordered a slightly shorter main an-4 line with a 90 fitting. My old one was a little long. It looks like I get to keep the old line AND have a bleed line that is too long. Yipee.

I finally got everything measured for the shims stack on the back of the throw-out bearing and got everything set up.

I was also having a slight problem with the fittings rubbing on the pressure plate if the throwout bearing over-traveled. I carefully shaved down the lip on the pressure plate with a flap disc. I gained about 1/16-1/8" clearance. I will just have to be really careful with the clutch pedal stroke adjustment again.

I finally got the adapter all assembled and the bellhousing on the transmission. Overall the fit of the adapter was really nice. I had to file the upper left transmission ear a bit more to get everything to line up during assembly. Novak includes 4 threaded studs to mate up the lower mounting holes. I waited to install these until after the upper two 1/2-13 bolts where started. To do this I had to double nut the studs to run them in. They are a pretty tight fit but I was able to use a totally factory bellhousing.

Next I can bolt the bellhousing to the engine and then I can drop the whole mess back in the chassis this weekend! I will feel a LOT better when the engine/transmssion/t-case are all bolted in.....

This seems to be the proper unit for my application ( Buick 225 odd fire V6 ). It is the same size as what was in the vehicle before with the SM420 transmission BUT has a 1.060" 10 spline hub. This clutch is from a 1979 CJ5/7 with the I6 engine. I think this would have been the factory application for my T18 transmission.

I didn't have a clutch alignment tool, so I turned one down on the lathe out of some scrap bar stock. Yet another reason to have a lathe in your shop. I am on the fence with what would be more useful....mill or lathe. I know I will have a HARD time if I can't have a lathe anymore.

This was my big issue for the night. I transfered over my existing hydraulic throw-out bearing to the new transmission configuration.

http://www.speedwaymotors.com/GM-Stock-Clutch-Hydraulic-Throwout-Bearing,1945.html

I really wanted to add a remote bleed line to make life easier. I bought a straight 12" an-4 line to make into a bleed line but with the way the bearing retainer is orientated on the bellhousing adapter you really need a 90 degree fitting to get it going the right way. Luckly I had ordered a slightly shorter main an-4 line with a 90 fitting. My old one was a little long. It looks like I get to keep the old line AND have a bleed line that is too long. Yipee.

I finally got everything measured for the shims stack on the back of the throw-out bearing and got everything set up.

I was also having a slight problem with the fittings rubbing on the pressure plate if the throwout bearing over-traveled. I carefully shaved down the lip on the pressure plate with a flap disc. I gained about 1/16-1/8" clearance. I will just have to be really careful with the clutch pedal stroke adjustment again.

I finally got the adapter all assembled and the bellhousing on the transmission. Overall the fit of the adapter was really nice. I had to file the upper left transmission ear a bit more to get everything to line up during assembly. Novak includes 4 threaded studs to mate up the lower mounting holes. I waited to install these until after the upper two 1/2-13 bolts where started. To do this I had to double nut the studs to run them in. They are a pretty tight fit but I was able to use a totally factory bellhousing.

Next I can bolt the bellhousing to the engine and then I can drop the whole mess back in the chassis this weekend! I will feel a LOT better when the engine/transmssion/t-case are all bolted in.....

Metcalf

Expedition Leader

Back at it this evening. I tried not to overdo it....

Everything is all bolted together now. A piece of 3/8-16 all thread has to be one of the most handy things ever. Here, it works really good as a way to help get everything aligned when trying to float the engine, transmission, and transfer case all together at once. Works like a charm!

I was terrible about getting pictures but I tidied up a few other things...

-Phoned a friend and found a number to torque the D18 input gear nut to. That ended up being 125ft lbs.

-Installed the PTO cover with a new gasket and some 'right stuff'

-Trimmed the tunnel back another 2.75" to the rear for the new assembly. I think I still have a little more trimming to do on the passenger side but I don't want to get into the hat channel if I can help it.

-Tried to prep the edges of the tunnel cuts for welding on the top and bottom.

-scrapped a few pounds of dirt, undercoating, and gear lube off the bottom of the bottom of the tub.....eeeewwwwwwwww....

I think tomorrow I will be ready to fly the powertrain into the chassis!

Everything is all bolted together now. A piece of 3/8-16 all thread has to be one of the most handy things ever. Here, it works really good as a way to help get everything aligned when trying to float the engine, transmission, and transfer case all together at once. Works like a charm!

I was terrible about getting pictures but I tidied up a few other things...

-Phoned a friend and found a number to torque the D18 input gear nut to. That ended up being 125ft lbs.

-Installed the PTO cover with a new gasket and some 'right stuff'

-Trimmed the tunnel back another 2.75" to the rear for the new assembly. I think I still have a little more trimming to do on the passenger side but I don't want to get into the hat channel if I can help it.

-Tried to prep the edges of the tunnel cuts for welding on the top and bottom.

-scrapped a few pounds of dirt, undercoating, and gear lube off the bottom of the bottom of the tub.....eeeewwwwwwwww....

I think tomorrow I will be ready to fly the powertrain into the chassis!

Metcalf

Expedition Leader

Good day!!!

Got the Y-pipe bolted up. It pretty much fit like before with a little more room around the front of the transmission since it is slightly further back with the Novak adapter now....

FLY BABY FLY!!!!!!

In goes the Buick 225, new T18, and new D18!

The tilting engine cradle made this a one man operation. It took about 1.5 hours to get to the point where the motor mount bolts would go in, BUT IT'S BACK IN! That feels good......

Here it is back in its home....

I had to use a large ratchet strap on the transmission to help get everything all leveled out to get the engine hoist pick point further forward to fully drop the engine on the mounts.

I got the transmission jacked, strapped, and pulled into its approximate new home. After a few minor cuts here and there it is almost in its final resting place! I still have a few more little cuts to make for more clearance if things start to move around. All in all not that bad though....

I think I will be able to make a much smaller tunnel this time around by fully welding it in. It might take a little more detail work but having the tunnel be a little smaller would sure be nice around my right foot area.

Clearance under the belly looks to be about the same, maybe 1/4-1/2" less at most. It looks like I will even be able to reuse most of my old transmission crossmember but with some mods.

Tomorrow hopefully I can finish trimming the floor and get the crossmember mounted up. I also need to build another fixed mount for the exhaust y-pipe off the pto cover bolts or something.....

Got the Y-pipe bolted up. It pretty much fit like before with a little more room around the front of the transmission since it is slightly further back with the Novak adapter now....

FLY BABY FLY!!!!!!

In goes the Buick 225, new T18, and new D18!

The tilting engine cradle made this a one man operation. It took about 1.5 hours to get to the point where the motor mount bolts would go in, BUT IT'S BACK IN! That feels good......

Here it is back in its home....

I had to use a large ratchet strap on the transmission to help get everything all leveled out to get the engine hoist pick point further forward to fully drop the engine on the mounts.

I got the transmission jacked, strapped, and pulled into its approximate new home. After a few minor cuts here and there it is almost in its final resting place! I still have a few more little cuts to make for more clearance if things start to move around. All in all not that bad though....

I think I will be able to make a much smaller tunnel this time around by fully welding it in. It might take a little more detail work but having the tunnel be a little smaller would sure be nice around my right foot area.

Clearance under the belly looks to be about the same, maybe 1/4-1/2" less at most. It looks like I will even be able to reuse most of my old transmission crossmember but with some mods.

Tomorrow hopefully I can finish trimming the floor and get the crossmember mounted up. I also need to build another fixed mount for the exhaust y-pipe off the pto cover bolts or something.....

Metcalf

Expedition Leader

Ok, time for people to post up there ideas and input on building a new tunnel!

My thoughts....

-The previous removable tunnel was a bit big. I think I can make this one smaller and tighter to everything. With the poly torque mount the transmission and transfer case don't move around that much.

-How tight to make it? Should I leave about a 1/2" of clearance? Enough to get a finger inbetween everything?

-Welding the tunnel in place or making it removable? With the transmission and transfer case this high in the chassis I don't think I have a hope of being able to dump the transmission off the back of the engine in the chassis. The transfer case is pretty far above the floor. I do think that I want to make a section or two of the tunnel removable however.

-Being able to remove the top cover of the transmission would be nice. This allow you to limp off the trail if you happen to break a shift fork. I have had to do this at least once or twice in my wheeling experience. Being able to do this without having to remove the seats is nice. Mine come out pretty easy so that isn't a deal breaker.

-Being able to get access to the twin stick shifter pin retaining bolt, grease fitting, and front drive-shaft yoke nuts from the TOP is nice. I think this would be the most used removable panel. This would also let me get at the torque mount from the top which would be nice.

-I plan on having a fill port for the transfer case in the top of the case just behind the twin stick shifter boot, maybe just behind it.

-I want to be able to run a regular twin stick shifter boot

-I want to be able to run a somewhat sealed shifter boot ( rubber?) on the transmission shifter to keep water from going down the shift lever into the transmission.

Anyone have any other ideas I need to be thinking about?

My thoughts....

-The previous removable tunnel was a bit big. I think I can make this one smaller and tighter to everything. With the poly torque mount the transmission and transfer case don't move around that much.

-How tight to make it? Should I leave about a 1/2" of clearance? Enough to get a finger inbetween everything?

-Welding the tunnel in place or making it removable? With the transmission and transfer case this high in the chassis I don't think I have a hope of being able to dump the transmission off the back of the engine in the chassis. The transfer case is pretty far above the floor. I do think that I want to make a section or two of the tunnel removable however.

-Being able to remove the top cover of the transmission would be nice. This allow you to limp off the trail if you happen to break a shift fork. I have had to do this at least once or twice in my wheeling experience. Being able to do this without having to remove the seats is nice. Mine come out pretty easy so that isn't a deal breaker.

-Being able to get access to the twin stick shifter pin retaining bolt, grease fitting, and front drive-shaft yoke nuts from the TOP is nice. I think this would be the most used removable panel. This would also let me get at the torque mount from the top which would be nice.

-I plan on having a fill port for the transfer case in the top of the case just behind the twin stick shifter boot, maybe just behind it.

-I want to be able to run a regular twin stick shifter boot

-I want to be able to run a somewhat sealed shifter boot ( rubber?) on the transmission shifter to keep water from going down the shift lever into the transmission.

Anyone have any other ideas I need to be thinking about?

Metcalf

Expedition Leader

Another good night...

The crossmember only needed a little trimming to pass under the back of the new T18 with the transmission in the final position. I forgot to get a pic with the patch panel welded in and ground smooth. You will never see it really bit it turned out pretty decent.

The patch was just some 1/8" plate cut out on the little bandsaw and bent in the vise. I need to make a little press brake one of these days, that would be super handy. Oh, and if Santa could get me one of those 12" disc sanders that would be great....

Here is the transmission with its weight on the crossmember. I need to make a bracket to hold the exhaust Y-pipe up again. The yoke has about 1/2-5/8" before it hits the hat channel on the body.

Overall I am pretty happy with the final position. Next I need to build a new transmission mount assembly. It will be pretty similar to the old version but will have to be slightly lower I think. The T18 is deeper from center-line to the bottom of the transmission I think so it hangs down slightly more.

I still have about 17" under the transmission which isn't bad for a stupid low flat fender on 35's. I am going to tuck a small aluminum skidplate under everything once I stop changing things.

This was a super nice bonus! The stock shift rod and top cover fit under the dash without any mods. Its probably a touch to close to use stock, not to mention the shift lever would SUPER long at about the same level as my face! I will only have to slightly bend the lower end of the shifter for a bit more clearance in 1st gear and shorten it to a comfortable height. That is MUCH easier than I had it with the SM420. There should also be plenty of room for a normal shift boot on both the transmission and transfer case shift levers. H

Hopefully tomorrow I can get a bit further along with the exhaust mount, transmission mount system. Then I need to do the torque mount mods.

Fun stuff.....

The crossmember only needed a little trimming to pass under the back of the new T18 with the transmission in the final position. I forgot to get a pic with the patch panel welded in and ground smooth. You will never see it really bit it turned out pretty decent.

The patch was just some 1/8" plate cut out on the little bandsaw and bent in the vise. I need to make a little press brake one of these days, that would be super handy. Oh, and if Santa could get me one of those 12" disc sanders that would be great....

Here is the transmission with its weight on the crossmember. I need to make a bracket to hold the exhaust Y-pipe up again. The yoke has about 1/2-5/8" before it hits the hat channel on the body.

Overall I am pretty happy with the final position. Next I need to build a new transmission mount assembly. It will be pretty similar to the old version but will have to be slightly lower I think. The T18 is deeper from center-line to the bottom of the transmission I think so it hangs down slightly more.

I still have about 17" under the transmission which isn't bad for a stupid low flat fender on 35's. I am going to tuck a small aluminum skidplate under everything once I stop changing things.

This was a super nice bonus! The stock shift rod and top cover fit under the dash without any mods. Its probably a touch to close to use stock, not to mention the shift lever would SUPER long at about the same level as my face! I will only have to slightly bend the lower end of the shifter for a bit more clearance in 1st gear and shorten it to a comfortable height. That is MUCH easier than I had it with the SM420. There should also be plenty of room for a normal shift boot on both the transmission and transfer case shift levers. H

Hopefully tomorrow I can get a bit further along with the exhaust mount, transmission mount system. Then I need to do the torque mount mods.

Fun stuff.....

Similar threads

- Replies

- 7

- Views

- 835

- Replies

- 4

- Views

- 2K

- Replies

- 65

- Views

- 6K