matt s

Explorer

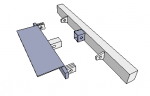

I have a working example of this on my rig now. Mine is for my snowplow but the theory is the same. A three point mount to eliminate some of the possible damage from side load (or torque/twisting in my case). I don't have a photo, but will get one for you later. Mine is simple. I have a front receiver, and I also already have mounts for a tow bar just below the bumper on the frame. The tow bar mounts with half inch pins. My friend and I fabbed up a mount that comes out of the receiver and then drops below the bumper where it hits a spreader bar that then goes back to the tow bar mounts. The end result is amazingly strong, tight and easy to put on and off with only a mallet to help with sometimes tight pins (temperature seems to play a roll here, if it's at the temp we fabbed at it fits perfect, other than that and the pins need a little enticement).

the main benefit (other than not adding anything to the rig to mount the plow) is that when removed the license plate goes back in the receiver, and the tow bar mounts are very low profile. Over all it was way less impact on the vehicle in terms of permanent mounts hanging all over the place.

the main benefit (other than not adding anything to the rig to mount the plow) is that when removed the license plate goes back in the receiver, and the tow bar mounts are very low profile. Over all it was way less impact on the vehicle in terms of permanent mounts hanging all over the place.

Last edited: