What you are erroneously calling a "seam" - and thus implying a potential point of failure - is what is called in injection/rotary moulding a 'parting line' and 'moulding flash' and is cosmetic only. It is not two halves melted together along that line.

Looking at their PDF data it would seem the wall thickness of the HDPE would be just over 2/3 that of the Scepter MFC, judging from the listed product weights. That's pretty good for a 'consumer' grade can, thicker than the old Blitz plastic cans were, anyway.

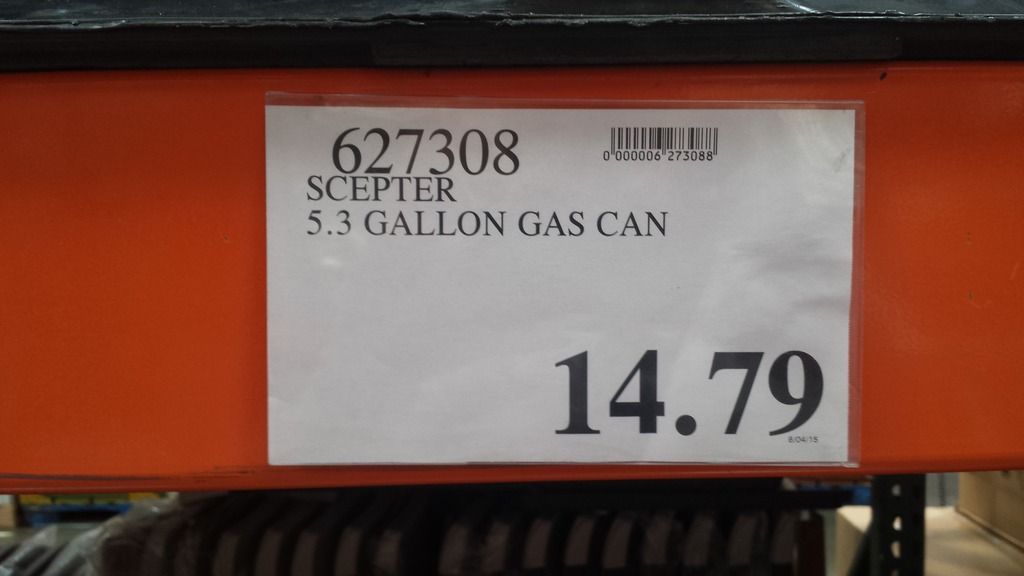

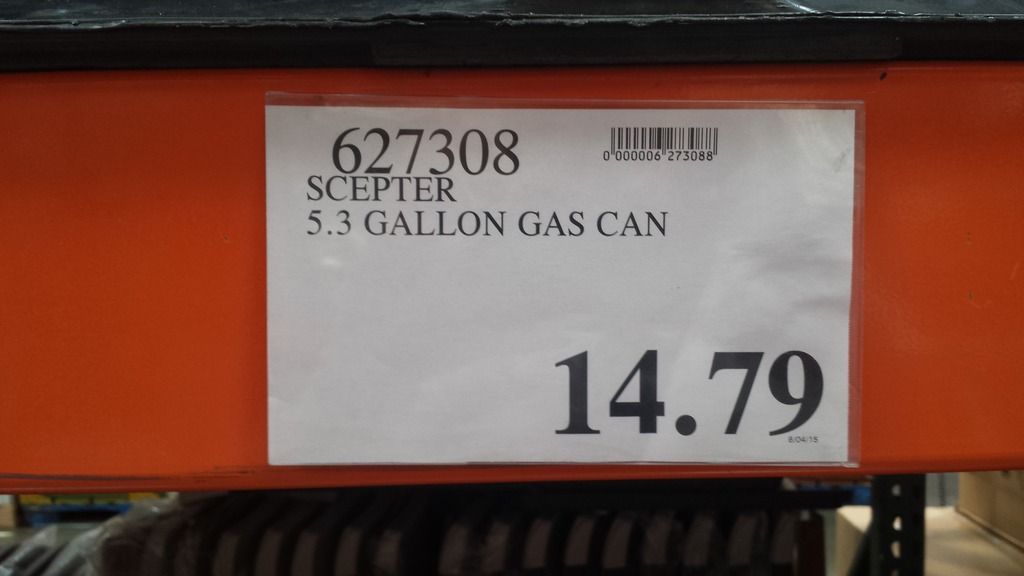

As to treating a plastic fuel can like a basketball, you better just go pony up $50-80 for a MFC, instead of holding a $15 can to that higher standard.

As to CARB nozzles, they are all utter crap for pouring. I don't even try. I use a SimpleSiphon. The caps are however sufficient against leaking when simply closed, or they couldn't get DOT approval for their basic tests.

It's a $15 consumer gas can. Judge it on its merits, not against something it isn't advertised to be.

------

http://www.scepterconsumer.com/sites/scepter_consumer_02/files/Scepter_EPA_Carb.pdf

RV520S - 20 L/5.3 Gal Military Style Gas

3.9 lbs/1.8 k

13.0" x 6.0" x 18.3"

http://civ.sceptermilitary.com/sites/scepter_militaryciv_02/files/scepter_military_catalogue.pdf

MFC, Fuel Can 5Gal/20L Diesel (Olive Drab with Yellow Strap)

5.71 lbs/2.59 kg

14.3" x 6.9" x 18.3" / 36.3 x 17.5 x 46.5

MFC, Fuel Can 2.5Gal/10L Gasoline (Olive Drab with Red Strap)

3.234 lbs/1.467 kg

13.6" x 6.6" x 11.8" / 34.5 x 16.7 x 30

------