wreckdiver1321

Overlander

So I spent some time doing a little work on the Cruiser last night and had a chat with my friend who has been helping me work on it. After getting into the minutia, I think I've deciphered my main concerns with regards to the rust:

1. Body. Just about everything above the side molding is in great shape, but things below there are less so. Most of it is still solid, with a few bits here or there. My concern, more than anything else, is that the rockers or pinch weld might rot and I'll spend the next several years playing catch-up or futilely trying to repair them. I'm not overall concerned with any other parts of it. Pretty much everything else is easy to either repair or replace the panel.

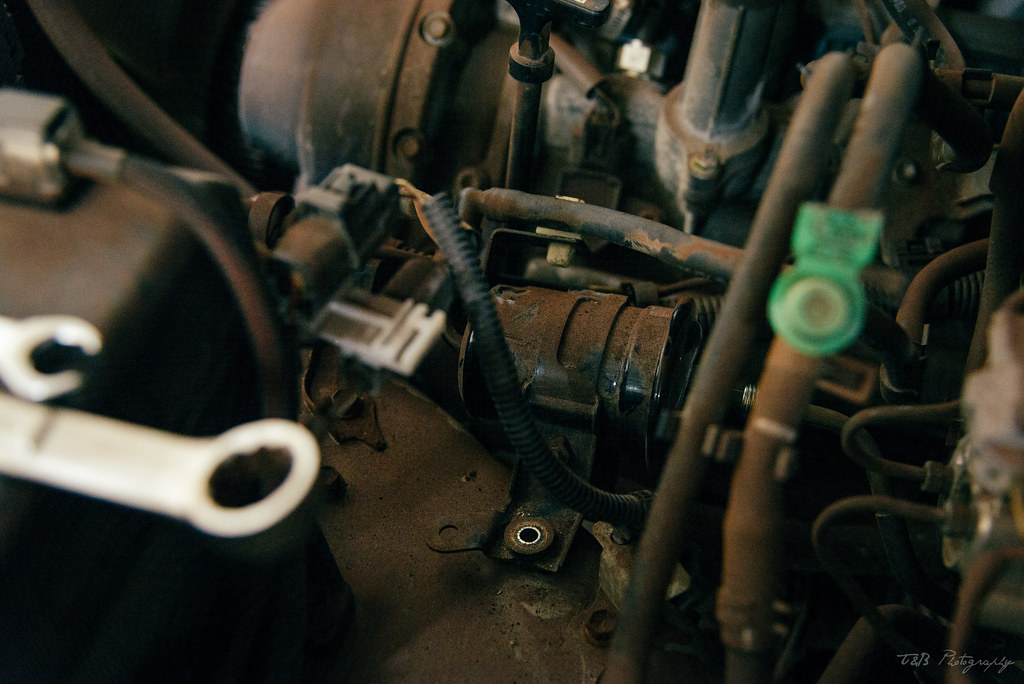

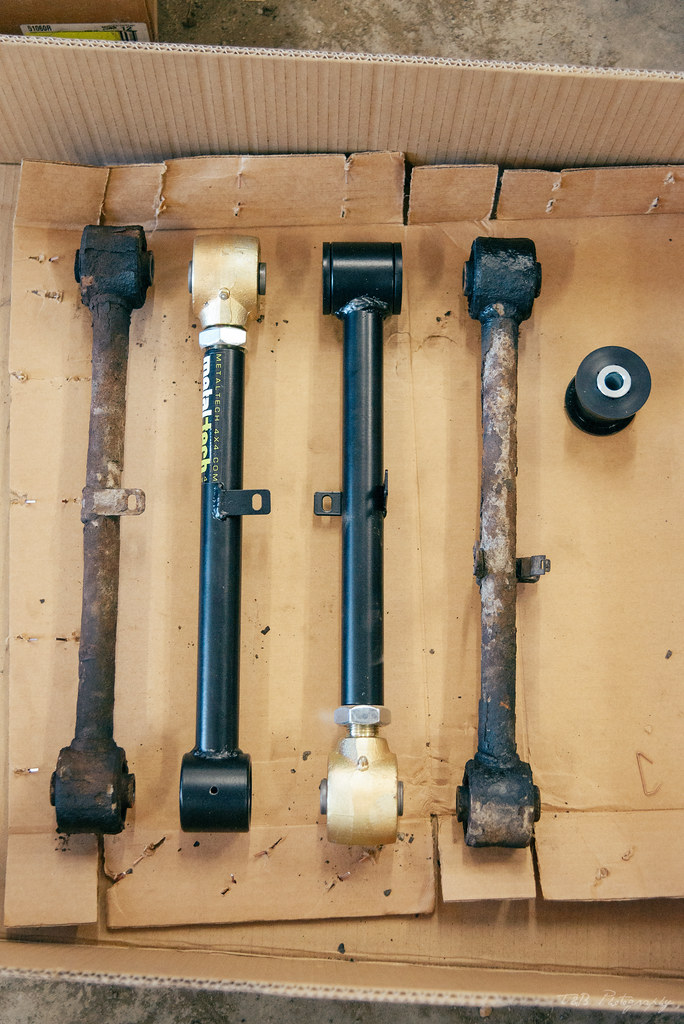

2. Rear end. I'm utterly and completely unconcerned with everything underneath from the rear LCA frame mounts forward. All of that is in pretty good shape and cleaned up really nicely. There's barely any pitting in most spots. What does worry me are things like the rear control arm mounts on the diff. I'm not necessarily concerned that the diff itself will crack or something, but I do worry that those mounts, being a thinner material, will. I'm also worried about brake lines, but those are a simple thing to remedy. I worry about the upper shock mounts because we weren't able to do a stellar job reaching the top of them for rust removal. I do worry a tiny bit about the very back of the frame near the rearmost crossmember, but I think with the bumper mounting plates and hitch receiver, which I may weld on, there's plenty of beef there to keep it going indefinitely.

What does ExPo think? Most of these issues are solved by replacing the rear diff with a locked one from 98 or 99. If I do that and replace the factory fuel tank with an LRA 40 gal, I could probably reach those top shock mounts more easily and fix my concerns with the control arm mounts. I can always weld more steel to the back of the frame too if I get concerned.

1. Body. Just about everything above the side molding is in great shape, but things below there are less so. Most of it is still solid, with a few bits here or there. My concern, more than anything else, is that the rockers or pinch weld might rot and I'll spend the next several years playing catch-up or futilely trying to repair them. I'm not overall concerned with any other parts of it. Pretty much everything else is easy to either repair or replace the panel.

2. Rear end. I'm utterly and completely unconcerned with everything underneath from the rear LCA frame mounts forward. All of that is in pretty good shape and cleaned up really nicely. There's barely any pitting in most spots. What does worry me are things like the rear control arm mounts on the diff. I'm not necessarily concerned that the diff itself will crack or something, but I do worry that those mounts, being a thinner material, will. I'm also worried about brake lines, but those are a simple thing to remedy. I worry about the upper shock mounts because we weren't able to do a stellar job reaching the top of them for rust removal. I do worry a tiny bit about the very back of the frame near the rearmost crossmember, but I think with the bumper mounting plates and hitch receiver, which I may weld on, there's plenty of beef there to keep it going indefinitely.

What does ExPo think? Most of these issues are solved by replacing the rear diff with a locked one from 98 or 99. If I do that and replace the factory fuel tank with an LRA 40 gal, I could probably reach those top shock mounts more easily and fix my concerns with the control arm mounts. I can always weld more steel to the back of the frame too if I get concerned.