AdventureBus

Active member

Hello folks,

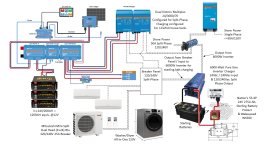

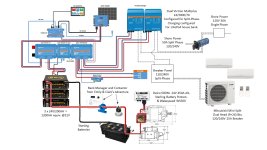

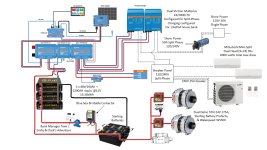

I have been planning the electrical system for my rugged adventure bus and would like some feedback on my design. This is a simple diagram and does not include all of the wiring, fuses, switches, etc. that is will need but serves as a preliminary planning tool.

Link to my build thread: https://forum.expeditionportal.com/threads/international-3800-adventure-bus-build.219248/

Some things I desire from my system:

Unique features of this system not found in most RVs:

Issues to mitigate (need help with this):

I have been planning the electrical system for my rugged adventure bus and would like some feedback on my design. This is a simple diagram and does not include all of the wiring, fuses, switches, etc. that is will need but serves as a preliminary planning tool.

Link to my build thread: https://forum.expeditionportal.com/threads/international-3800-adventure-bus-build.219248/

Some things I desire from my system:

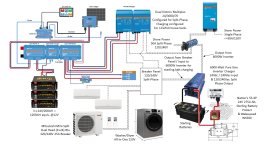

- Ability to power 120/240V split-phase dual head mini-split while on the road

- Enough alternator and battery bank capacity to be conservative with power demands

Unique features of this system not found in most RVs:

- Converting alternator power to split-phase 120/240V and passing it through the AC input of the Multiplus'

- Multiplus' stacked and configured for 120/240V split-phase output

- Ability to utilize Multiplus PowerAssist feature to supplement alternator/inverter power with LiFePo4 house bank

- 4 position switch for 50A split-phase 120/240V input, 30A/50A single-phase to split-phase input via Autotransformer, 6000W split-phase 120/240V input from alt/inverter

- Multiplus' will always be supplied with split-phase input and thus shouldn't need software configuring when changing input switch

Issues to mitigate (need help with this):

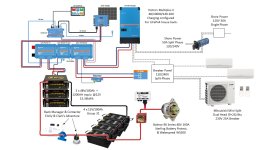

- Need to protect alternator from overworking/overheating

- Plan to use Wakespeed WS500 and regulate alternator output with temperature sensors and conservative expectations

- Need to protect alternator and other components from load dump from LFP BMS disconnect

- Will the starting batteries provide an adequate buffer for voltage spikes from load dump?

- Alternator will have avalanche diodes

- Will probably use Sterling alternator protection device as additional insurance