luthj

Engineer In Residence

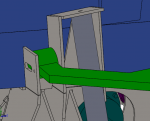

More minor refinements, trying to get bumpstop height more precise. This is a bit of a challenge with the compound curves of the lower A-arm

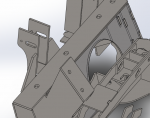

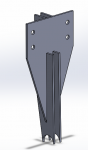

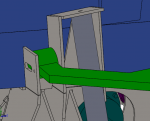

Roughed in a shock tower. I think I will provision for 2 through bolts to secure the tower, with backing plates in the engine compartment. The cycling loading on the tower is substantial.

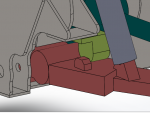

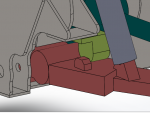

I think I have settled on a engine mount design. I will probably leave the isolator mounting holes out, and drill them during final assembly. Just depends on how accurate of measurements I can get. There is a fair bit of room in the engine bay, but I am trying to avoid moving the engine/trans more than 1/4" from its current position. Though I can lower it about 1/2" at the front if needed to change driveline angles.

Roughed in a shock tower. I think I will provision for 2 through bolts to secure the tower, with backing plates in the engine compartment. The cycling loading on the tower is substantial.

I think I have settled on a engine mount design. I will probably leave the isolator mounting holes out, and drill them during final assembly. Just depends on how accurate of measurements I can get. There is a fair bit of room in the engine bay, but I am trying to avoid moving the engine/trans more than 1/4" from its current position. Though I can lower it about 1/2" at the front if needed to change driveline angles.