p1michaud

Expedition Leader

Tacoma rear bumper build up.

Hi folks. I'm in the process of researching my rear bumper build and would like your advice.

Criteria:

I was fortunate enough to pick up a set of Demello Off-Road bumper mounting brackets. These things are beefy. Pictures were taken by KStacoma over on TTORA (I bought the brackets from him).

Here is what I have in mind.

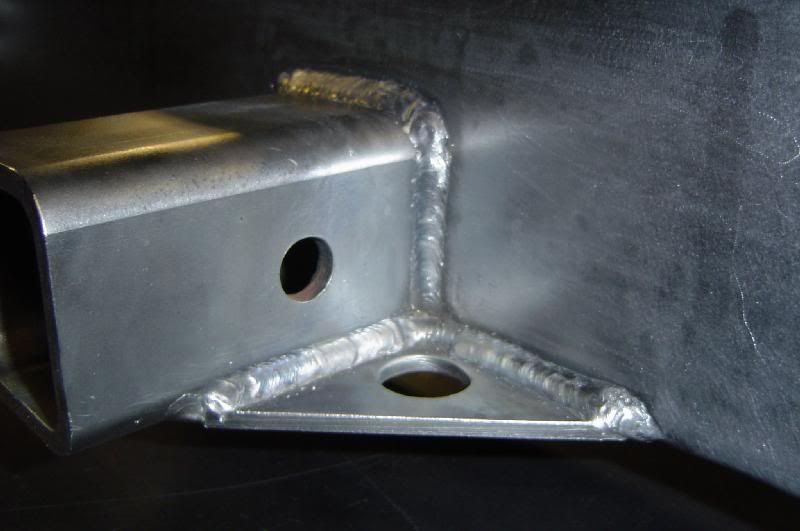

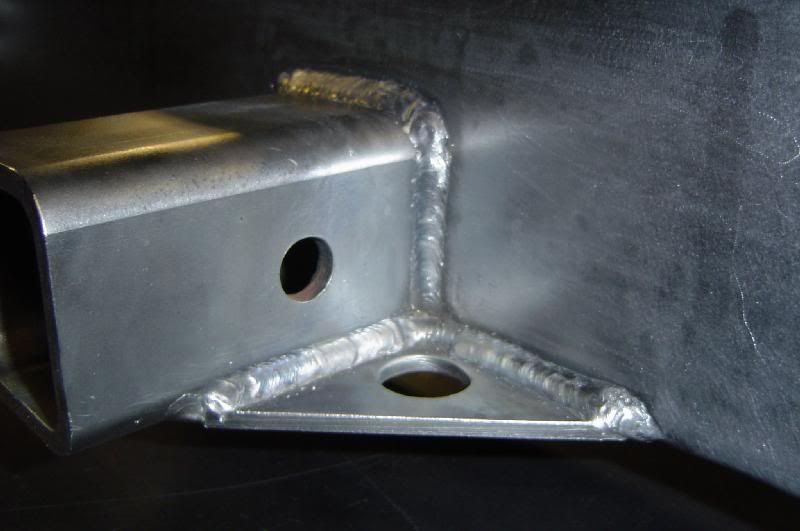

My plans are to use a 2" x 4", 3/16" thick for the main piece. My reason for choosing this thickness is that I'd like to build in the receiver into the main piece as shown here. I will also gusset the back side and provide a location for trailer chain hook ups such as this:

Alternatively, I could go with a 1/8" thick 2" x 4" but re-inforce it on the back side to allow for towing. Perhaps build in a piece of 2" x 2" x 1/4" for the with of the frame rails and brackets. I have to do a bit of match to consider if the weight savings would be worth it.

I will cut through both sides of the 2” x 4” piece and run a piece of 1/4 by 4” flat bar narrowed to suit that goes through and weld that in place on both sides. These will be the brackets that are used to bolt onto the Demello frame mounted brackets. They will also serve a shackle mounting brackets. They will have a 7/8” or 1” hole in them. I will double the thickness of the shackle mounting brackets by welding an additional piece of 1/4" pre-drilled plate to them. This will do two things: prevent the possibility of pulling the brackets through the bumper under load and provide a larger contact area for improved force distribution during recovery operations using a shackle (i.e. force distributed on 1/2" of metal vs. 1/4").

I really like the idea of what Zsazbo has done over on TTORA.

More pictures can be seen in the Rear bumper Rear bumper thread. This approach would allow for minimal weight when extra fuel or water is not required.

I'm thinking of doing a very similar variation except I'd use the Adventure Trailers Can Holders with them laying on their side as shown here.

Here is a very poor photochop job of what I mean:

I’ve butchered moutainpete’s rear bumper picture hope you don't mind.

Rear quarter panel protection may or may not incorporated. I’ve not decided yet but really like the Demello Off-Road hybrid design. The other alternative is to cut the bed similar to what Will has done:

I'm still torn with respect to side protection. I don’t have a problem removing some sheet metal but my wife thinks that looks ugly! :costumed-smiley-007. The other issue with going this route, it’s not reversible. The bumper would have to be sold with the truck when I change. If I don’t cut the bed, the bumper could be transferred to the next vehicle assuming they are compatible.

So, here is your chance to provide some input. Let’s hear it!

Cheers :beer:,

P

Hi folks. I'm in the process of researching my rear bumper build and would like your advice.

Criteria:

- Weight is a concern, so I want to find a balance between strong yet no too heavy.

- Versatile. My rig is used as a DD, for exploring, camping, hunting, fishing, sometimes towing ( a few times a year perhaps). I need it to be functional yet versatile.

- I don't want to remove the spare from the stock location.

- Location to carry Scepter Military cans (Fuel and Water) would be a benefit and they must be lockable..

- Location to mount Hi-Lift would also be a benefit and it must be lockable.

I was fortunate enough to pick up a set of Demello Off-Road bumper mounting brackets. These things are beefy. Pictures were taken by KStacoma over on TTORA (I bought the brackets from him).

Here is what I have in mind.

My plans are to use a 2" x 4", 3/16" thick for the main piece. My reason for choosing this thickness is that I'd like to build in the receiver into the main piece as shown here. I will also gusset the back side and provide a location for trailer chain hook ups such as this:

Alternatively, I could go with a 1/8" thick 2" x 4" but re-inforce it on the back side to allow for towing. Perhaps build in a piece of 2" x 2" x 1/4" for the with of the frame rails and brackets. I have to do a bit of match to consider if the weight savings would be worth it.

I will cut through both sides of the 2” x 4” piece and run a piece of 1/4 by 4” flat bar narrowed to suit that goes through and weld that in place on both sides. These will be the brackets that are used to bolt onto the Demello frame mounted brackets. They will also serve a shackle mounting brackets. They will have a 7/8” or 1” hole in them. I will double the thickness of the shackle mounting brackets by welding an additional piece of 1/4" pre-drilled plate to them. This will do two things: prevent the possibility of pulling the brackets through the bumper under load and provide a larger contact area for improved force distribution during recovery operations using a shackle (i.e. force distributed on 1/2" of metal vs. 1/4").

I really like the idea of what Zsazbo has done over on TTORA.

More pictures can be seen in the Rear bumper Rear bumper thread. This approach would allow for minimal weight when extra fuel or water is not required.

I'm thinking of doing a very similar variation except I'd use the Adventure Trailers Can Holders with them laying on their side as shown here.

Here is a very poor photochop job of what I mean:

I’ve butchered moutainpete’s rear bumper picture hope you don't mind.

Rear quarter panel protection may or may not incorporated. I’ve not decided yet but really like the Demello Off-Road hybrid design. The other alternative is to cut the bed similar to what Will has done:

I'm still torn with respect to side protection. I don’t have a problem removing some sheet metal but my wife thinks that looks ugly! :costumed-smiley-007. The other issue with going this route, it’s not reversible. The bumper would have to be sold with the truck when I change. If I don’t cut the bed, the bumper could be transferred to the next vehicle assuming they are compatible.

So, here is your chance to provide some input. Let’s hear it!

Cheers :beer:,

P

Last edited: