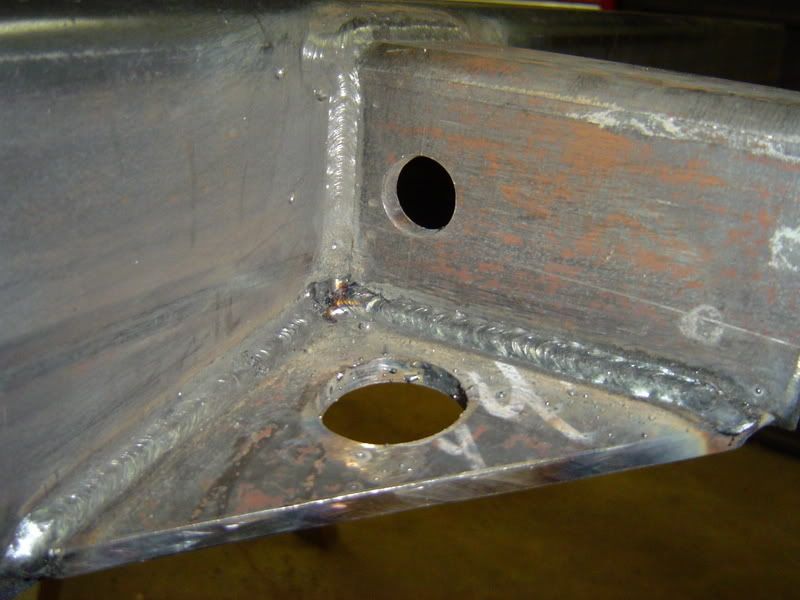

Side protection

Willman said:

Your welds are getting cleaner as i look down the page! I can see the rust coming off!!!! Great job!

Old welding rods = bad welds. On my fist welds for the receiver tube gussets, there was quite a bit of spattering due to old welding rods. I picked up a new box of rods and I put the few old rods I had left on the wood stove to "dry" them out a bit this helped out with the weld quality.

Willman said:

What are you going to do for side protection? (tube or sheet metal?)

At this point, I'm still torn with respect to side protection. The way I see it I've got four options listed in order of preference:

1-Tube wrap around style similar to the Demello Off-Road wrap arround or what you did here:

Photo credit: Willman

This is my favourite option by the way, but no one locally can bend tubing. Everyone I spoke to has pipe benders as opposed to tube benders. I'd like to go with 1 3/4" by 0.120" wall for this option. The closest thing to this in pipe would be 1 1/4" SCH 40 but that's got a nominal OD of 1.66” and a 0.140" wall that "costs" me 2.27 lb/ft. Too heavy IMO.

2-I really feel like removing some sheet metal similar to what Wil has done below but my wife thinks that looks ugly plus it may become an issue for resale down the road.

Photo credit: flyingwil

3-Do nothing, that is no side protection. This one is really tempting me for the following reasons:

- Weight savings

- I have not needed yet

- Easier to build the bumper although I would make the bumper build such that it could be incorporated later.

- If I damage a quarter panel, I can always resort to option 2 from this list!

My wife actually suggested this option, when she said: “You know, sometimes less is more…”.

4--Some version of side protection similar to what Steve from Sonoran Steel fabrication has done for his

1995-2004 Toyota Tacoma Rear Bumper with Side Wings (near bottom of the page).

Not sure at this point, I have to think about it more. Now I have to wait to pick up my hinges and toggle clamps before progressing.

Cheers,

P