dieselBlazer

New member

I have an old K5 blazer that I added pressurized water to a few years ago and I like it. Its a simple system using a single 5 gal water can on my bumper swing out that I added an RV faucet to, and a pressurized air line coming off a ~7 psi regulator from my on board air. The 5 gal container is not a pressure vessel and it worked well for years, but lately has started leaking air from the lid. And the last couple trips I have taken into the high desert the exposed tap has frozen overnight and taken until after noon the next day to defrost enough to be used.

I am working on an upgraded system and would like any input you might have. Requirements for the new system:

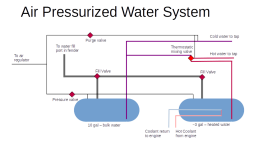

One solution seems to be a bigger, better system that is air pressurized like what I already have. I already have powerful oilless compressors, an air tank and an appropriate regulator installed in my truck that can all be reused. The diagram and notes below shows what I have in mind:

Total cost for this system would be $350 in kegs, $150 for cheap 1.5" stainless solenoids for the fill valves, and whatever it costs for the thermostat valve and PEX tube for water lines. I already have a ton of 3/8" air valves, tube and fittings left over from other projects that I can use, and I have copper tube to make the heat exchanger. I can do all the stainless welding to modify the kegs myself, and I can fabricate the heat exchanger myself.

To do an electric system with pumps I would still need a 10 gal tank, but it could be plastic and somewhat cheaper than a $200 keg. And I would not need the 1.5" stainless valves. But offsetting that cost I would need to buy a pump and accumulator. I think the hot water tank would still need to be metal to take the heat and pressure (I assume it would be fed from the main tank and thus pressurized by the pump, if not a second pump would be needed), and all the water plumbing and thermostat valve would be the same for either system. I don't see how it would be possible to fully drain the pump, lines and tap in an electric system every night and I don't know how I would prevent it from freezing. If I use an accumulator tank I think it might also be heavier than the air pressurized system, but using a demand pump without an accumulator would be lighter.

What do you think? Am I missing something obvious, or is air pressurized the way to go? If I did a pump and accumulator system how would you prevent the tap, lines and pump from freezing?

I am working on an upgraded system and would like any input you might have. Requirements for the new system:

- 10+ gallon capacity

- 2-3 gallons of heated water (mostly for washing dishes, tea/coffee, filling a nalgene bottle to put in the end of a sleeping bag on a cold night)

- strongly prefer using a heat exchanger with engine coolant to heat the water, like an isotemp

- No freezing with overnight temps in the 20s (F)

- All tanks and lines must be outside the passenger compartment. My Blazer is far too small to fit any water tanks inside (cargo area is less than 3' from tailgate to rear seat, and half of that space is permanently filled with a fridge/stove/tools)

One solution seems to be a bigger, better system that is air pressurized like what I already have. I already have powerful oilless compressors, an air tank and an appropriate regulator installed in my truck that can all be reused. The diagram and notes below shows what I have in mind:

- There would be 2 tanks (10 gal and 3 gal kegs from a brewing supplier, like this). To fill the tanks, open the Fill Valves (normally closed electric solenoid valves) and pour water into a fill port in the fender. This would be beneath an access door like the gas tank filler neck. Once the tanks are full close the fill valves, sealing the system air tight.

- To use the system, open the Pressure Valve and apply regulated air pressure to the tanks. Water is forced out of the tanks through the red and purple lines to the tap on the bumper swingout.

- Since the hot tank is heated by engine coolant (195-225F) a thermostat valve is needed to prevent scalding water from reaching the tap.

- At 20 psi the boiling point of water is raised to 260F so there is no risk of boiling the water in the tank, but it could still be dangerously hot.

- If low overnight temperatures are expected, close the Pressure Valve and open the Fill Valves to vent the tanks to atmosphere. Open the Purge Valve to blow air back through the lines and force all the water back into the tanks. Then close the Fill Valves and open the tap to allow air pressure to blow any remaining water out of the other side of the line and out of the tap.

Total cost for this system would be $350 in kegs, $150 for cheap 1.5" stainless solenoids for the fill valves, and whatever it costs for the thermostat valve and PEX tube for water lines. I already have a ton of 3/8" air valves, tube and fittings left over from other projects that I can use, and I have copper tube to make the heat exchanger. I can do all the stainless welding to modify the kegs myself, and I can fabricate the heat exchanger myself.

To do an electric system with pumps I would still need a 10 gal tank, but it could be plastic and somewhat cheaper than a $200 keg. And I would not need the 1.5" stainless valves. But offsetting that cost I would need to buy a pump and accumulator. I think the hot water tank would still need to be metal to take the heat and pressure (I assume it would be fed from the main tank and thus pressurized by the pump, if not a second pump would be needed), and all the water plumbing and thermostat valve would be the same for either system. I don't see how it would be possible to fully drain the pump, lines and tap in an electric system every night and I don't know how I would prevent it from freezing. If I use an accumulator tank I think it might also be heavier than the air pressurized system, but using a demand pump without an accumulator would be lighter.

What do you think? Am I missing something obvious, or is air pressurized the way to go? If I did a pump and accumulator system how would you prevent the tap, lines and pump from freezing?