You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TerraLiner:12 m Globally Mobile Beach House/Class-A Crossover w 6x6 Hybrid Drivetrain

- Thread starter biotect

- Start date

biotect

Designer

.

And now, for a completely different topic! I was getting a bit tired of thinking only about combination bathtub/showers for RV's....

*****************************************

COE versus "Pusher" Engine Placement, Entrance Stairways,

and Locating Capstone Microturbines

*****************************************

dwh and I recently exchanged a few private messages, whose content seemed like it might usefully appear here in this thread. dwh gave me permission to repost his messages (he is very busy right now). So I've reposted dwh's messages and my replies below, in quick succession, but beginning with their origin in the "High Altitude Heating" thread.

After this sequential reposting, what then follows is the same exchange, along with additional information and images provided to round out the content. Although microturbines have been around for a while, their use as range-extenders for serial hybrid electric vehicles is relatively recent. And only in the last six or seven years have things really picked up, with big OEMs like Peterbilt, and potentially big end-users like Fedex and Walmart, giving the technology serious consideration. I then posted all the additional information below about Capstone microturbines fitted in various vehicles, because this is not common knowledge.

After that, I will respond to dwh's last private message. But needless to say, if anyone else has thoughts about microturbines and their best possible location in a large, 6x6, RTW (round the world), go-anywhere sort of motorhome, please feel free to chime in!

**************************************

The exchange began with one of my posts in the "High Altitude Heating" thread about "Ivan the Terrabus", a 6x6 vehicle used in Antarctica to ferry people between McMurdo station and the Pegasus airfield. In the post I wrote about how Ivan's pusher engine placement made possible a very generous and quite futuristic sort of entrance staircase -- see post #83 at http://www.expeditionportal.com/for...BEST-High-Altitude-Solution-for-Heating/page9 . Below is the post rewritten, after dwh's feedback.

I originally wrote that Ivan's deeply embedded entrance staircase did not seem compatible with a COE design. dwh's subsequent post and private message usefully corrected that mistaken assumption:

Of course, it's also worthwhile reposting some images of "Ivan the Terrabus" here in this thread, because Ivan is an excellent example of a large, 6x6, fully integrated, off-road capable vehicle. Not exactly a motorhome, but close enough.

**************************************

CONTINUED IN NEXT POST

.

And now, for a completely different topic! I was getting a bit tired of thinking only about combination bathtub/showers for RV's....

*****************************************

COE versus "Pusher" Engine Placement, Entrance Stairways,

and Locating Capstone Microturbines

*****************************************

dwh and I recently exchanged a few private messages, whose content seemed like it might usefully appear here in this thread. dwh gave me permission to repost his messages (he is very busy right now). So I've reposted dwh's messages and my replies below, in quick succession, but beginning with their origin in the "High Altitude Heating" thread.

After this sequential reposting, what then follows is the same exchange, along with additional information and images provided to round out the content. Although microturbines have been around for a while, their use as range-extenders for serial hybrid electric vehicles is relatively recent. And only in the last six or seven years have things really picked up, with big OEMs like Peterbilt, and potentially big end-users like Fedex and Walmart, giving the technology serious consideration. I then posted all the additional information below about Capstone microturbines fitted in various vehicles, because this is not common knowledge.

After that, I will respond to dwh's last private message. But needless to say, if anyone else has thoughts about microturbines and their best possible location in a large, 6x6, RTW (round the world), go-anywhere sort of motorhome, please feel free to chime in!

**************************************

The exchange began with one of my posts in the "High Altitude Heating" thread about "Ivan the Terrabus", a 6x6 vehicle used in Antarctica to ferry people between McMurdo station and the Pegasus airfield. In the post I wrote about how Ivan's pusher engine placement made possible a very generous and quite futuristic sort of entrance staircase -- see post #83 at http://www.expeditionportal.com/for...BEST-High-Altitude-Solution-for-Heating/page9 . Below is the post rewritten, after dwh's feedback.

I originally wrote that Ivan's deeply embedded entrance staircase did not seem compatible with a COE design. dwh's subsequent post and private message usefully corrected that mistaken assumption:

In these images, people standing next to the Terrabus' huge 6 foot tires provide another indication of size. Also notice the interesting drop-down entry staircase. I've not seen anything quite like this on other vehicles, in so far as the staircase seems to "nest" deeply inside the body of the vehicle, and opens not just from the side, but also from underneath. The hinge is located at least a foot or two in, relative to the side of the vehicle. The staircase then looks very "futuristic" when it opens, even though Ivan the Terrabus is now a fairly old vehicle.

Ivan the Terrabus is a "pusher" diesel, with the engine located in back, as suggested by pictures taken of the back of other Terrabuses in service in Canada -- see post #90 below, this page, standard ExPo pagination. It might be harder to configure such a deeply set entrance staircase in a COE design, albeit not impossible. See for instance the flat-nosed "Bluebird" bus at http://www.bargainbusnews.com/Buses/3818-1995BlueBirdTC-2000/3818-1995BlueBirdTC-2000-1.jpg , a COE bus with an embedded entryway (many thanks to dwh for providing this link). But perhaps not as deeply embedded as Ivan's staircase?

In particular, Ivan's front-end reminds me of the Rosenbaur Panther ARFF, whose pusher-diesel design enables the entire floor of the cab to drop really, really low. This dramatically improves access, giving fire-fighters the ability to quickly enter/exit the Rosenbauer Panther, despite the fact that it's a heavy truck with huge Michelin tires, terrific ground clearance, and a MAN SX-45 chassis -- see posts # 17 - #22, post # 19 in particular, at http://www.expeditionportal.com/for...xpedition-RV-w-Rigid-Torsion-Free-Frame/page2 and http://www.expeditionportal.com/for...xpedition-RV-w-Rigid-Torsion-Free-Frame/page3 .

Of course, the driver's position in Ivan the Terrabus is not low like the Panther, as evidenced by the photograph of Ivan's driver with his door open, below. But even still, in terms of overall exterior geometry up front, Ivan does seems vaguely reminiscent of the Panther; and so too, perhaps even more reminiscent of the front-end of the MAN HX and SX series of trucks? See posts #249 - #277, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page25 to http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page28 for lots of imagery and discussion.

For websites with information about Ivan the Terrabus, see http://www.caranddriver.com/features/polar-motion-a-look-inside-driving-in-antarctica-feature , http://www.caranddriver.com/photos-...el-to-and-from-mcmurdos-airfield-photo-396270 , https://www.facebook.com/pages/Ivan-the-Terra-Bus/185942968156281 , http://antarcticsun.usap.gov/features/contenthandler.cfm?id=2887 , http://antarcticsun.usap.gov/features/contentHandler.cfm?id=1866 , http://coldryandfarsouth.blogspot.it/2010/10/7-october-ivan-terra-bus.html , http://www.frozendentist.com/cool-polar-transports/ , and http://randy-joyofdiscovery.blogspot.it/2012/11/ivan-terra-bus.html .

From the last website just referenced:

One of the vehicles I drive almost daily is IVAN, the Terra bus. It's a huge passenger transport, 46' long, over 12' wide and 14' tall with tires that are almost 6' in diameter. It holds 56 passengers, 5 gallons (not quarts) of oil, 80 gallons of diesel fuel (66 Imperial gallons) and gets 4-5 mpg.

Ivan the Terra Bus is world famous, has it's own song ( http://www.youtube.com/watch?v=3KgYg8-J5Gs ) and a video of the driving conditions on the Pegasus road ( http://www.youtube.com/watch?v=H4aClRySy8Y )

Ivan's not a classy guy, but rather a functional piece of equipment with its very own style. Just don't ask him to turn on a dime. I love driving him and enjoy the challenge of trying to stay one step ahead of Ivan's quirky personality and massive turn radius. Ivan is turning 19 years old next month, with over 11,800 hours on his clock, and sadly, is showing his age. *Ivan was build in Calgary, Alberta, Canada in December, 1993.

Here are two videos of Ivan. The second shows how the entry staircase deploys:

*

For some blogs with pictures of Ivan, in no particular order, see http://newswatch.nationalgeographic...n-ice-arriving-in-mcmurdo-station-antarctica/ , http://antarcticfudgesicles.wordpress.com/page/4/ ,http://scrippsblogs.ucsd.edu/antarctica/2013/02/12/antarctica-first-impressions/ , http://www.ig.utexas.edu/people/staff/blank/projects/icecap/gallery.html , http://tea.armadaproject.org/weiss/1.2.2003.html , http://www.offroadexpress.co.nz/Forums/viewtopic.php?f=62&t=19634 , http://ciresblogs.colorado.edu/antarcticuavs/page/2/ , http://www.polartrec.com/expedition...s-in-the-southern-ocean/journals/2011-02-14-3 , http://3rdlevelnz.blogspot.com/2011/02/ground-transport-chatham-islands-style.html , http://dc-onice.blogspot.com/2008/11/sunday-afternoon-walk-to-mcmurdo.html , http://users.phys.psu.edu/~cowen/amanda/travel-log/pole-pictures.html , http://www.earthgauge.net/2010/arrival-and-ivan-the-terra-bus , http://icestories.exploratorium.edu/dispatches/finally-on-the-ice/ , http://www.phys.unsw.edu.au/~z3318051/spd/spd.php?date=20121223_John , http://www.phys.unsw.edu.au/~z3318051/spd/spd-allchron.php , http://blogs.oregonstate.edu/hailingfrozenthoughts/2011/11/06/ice-flight/ , http://rebeccapriestley.com/page/3/ , http://www.irmahale.com/1999f.html , http://superviolaman.blogspot.com/2011/10/antarctic-highlights.html , http://randy-joyofdiscovery.blogspot.com/2011/12/more-mcmurdo-randomness.html , https://downandout.wordpress.com/category/life/page/2/ , http://transportblog.co.nz/2013/02/05/magnetic-south-lessons-from-antarctica/ , http://starsandskiesandsuch.wordpress.com/author/starsandskiesandsuch/ , http://www.esrl.noaa.gov/gmd/Photo_...rys_Hall_Album/tn/Ivan the Terra bus.JPG.html , http://glacierexplorer.com/2012/11/inside-look-into-mcmurdo-research-station/ , http://amrc.ssec.wisc.edu/blog/2014/01/09/planes-trainings-and-snowmobiles-and-pegasus-aws/ , http://seatermonice.blogspot.com , http://www.steminaction.org/blog/2012/2/15/goodbyes.html , http://wy-mt.water.usgs.gov/projects/antarctica/htms/journal.htm , http://earthobservatory.nasa.gov/blogs/fromthefield/2011/12/01/we-are-in-antarctica/ , http://www.aspiringecologist.com/2011_10_01_archive.html , and http://brownpaperblueink.com/2013/04/

These make for fun and interesting reading, that is, if you're curious about what life is like for scientists and technicians working and exploring way, way down under.....:REOutIceFishing:

Of course, it's also worthwhile reposting some images of "Ivan the Terrabus" here in this thread, because Ivan is an excellent example of a large, 6x6, fully integrated, off-road capable vehicle. Not exactly a motorhome, but close enough.

**************************************

CONTINUED IN NEXT POST

.

Last edited:

biotect

Designer

..

CONTINUED FROM PREVIOUS POST

**************************************

Here is dwh's reply to that particular Terrabus post, in the same "High Altitude Heating" thread:

1. dwh's First Private Message

dwh then supplemented the above post with an additional private message:

2. biotect's Reply to dwh

To which I responded privately as follows. The first half:

The second half:

3. dwh's Second Private Message

Here was dwh's reply:

And here is the image:

On my own view dwh's third proposal for a front-accessible "pull out" microturbine generator, mounted on a tray, is simply brilliant. At one stroke this solves a problem that has been vexing me for most of this thread: that COE placement with a tilting cab undermines the possibility of a fully integrated design.

Recall that this problem was discussed at considerable length earlier in the thread -- see posts #110 - #114 , #119 - #120 - #127 , at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page11 , http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page12 , and http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page13 (standard ExPo pagination). See especially egn's deft summary of the various disadvantages of different kinds of engine placement on page 13, post #127, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page13 .

A fully integrated design seems only genuinely compatible with either:

(a) "Pusher" engine placement, allowing easy access to the engine at the back of the vehicle.

or

(b) CBE placement, allowing easy access to the engine by lifting the bonnet, as per Earthroamer and Tiger expedition vehicles, or Rob Gray's short-bonnet Wothahellizat.

or

(c) COE placement, via a lid inside the cab that opens up the engine tunnel.

The first pusher solution for an ICE engine is not desirable from my "design" point of view, because as explained in the first half of my reply to dwh, I want the vehicle to have a large drop-down deck in back, akin to Rob Gray's Wothahellizat. And a "pusher" engine placement in back would make that impossible.

Next, although I am personally not dead-set against the second CBE solution, many participants early on in the thread disliked it immensely, including grizzlyj and egn. They did not want a bonnet, no matter how short, compromising forward visibility of the terrain.

The third solution, access to the engine from inside the vehicle, has been instantiated in a number of fully integrated designs. See for instance: (1) Autobus Australia's "Tonto" off-road, all-terrain bus -- post #209, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page21 ; (2) Peter Thompson's Mañana "bad-road" motorhome -- post #212 at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page22 ; and (3) the Deco-Liner -- post #166 at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page17 .

However, in response to the last post, egn wrote:

So the third solution does not seem that attractive either, even though it's the solution that seems most compatible with a fully integrated design that is COE, and that would have a drop-down deck in back.

But everything changes if the engine is a range-extending microturbine, driving a generator. To begin with, ICE range-extenders that are only hooked up to generators are already much lighter than engines directly powering a vehicle's wheels. And for the same amount of power output, a microturbine genset is lighter still and more compact than an ICE. So as dwh suggests, a microturbine genset could be placed COE, but on a forward-sliding tray, thereby providing full 360-degree engine access for service, and eliminating any need to tilt the cab.

Again, this solves a basic design conundrum that has been vexing me for most of this thread, and I can't thank dwh enough for this brilliant, very simple, but perhaps not obvious solution.

This is also a solution that allows for the possibility of a very generously proportioned, deeply "embedded" entrance staircase, as per Ivan the Terrabus. As explained to dwh in my reply, another disadvantage of many COE truck designs is that one has to climb a vertical "step ladder" outside the vehicle in order to gain access to the cab. The bigger the ICE underneath, and the flatter the floor of the cab, the higher the climb. Whereas although a microturbine placed COE would still take up space, it would not take up nearly as much space as a powerful ICE. A microturbine (or even two microturbines, plural, for redundancy) would not be nearly as high. And so a flat-cab-floor -- which is a kind of "motorhome ideal", and also an ideal for COE truckers -- could be much lower. And a Terrabus-style broad and deep entrance staircase would be no problem at all.

I will address the other suggestions in dwh's second private message later in the thread, from post # 503 onwards -- see http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page51 .

**************************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

**************************************

Here is dwh's reply to that particular Terrabus post, in the same "High Altitude Heating" thread:

Also that stairway setup has been done quite a few times. All Terrain Warriors has done in on a few trucks:

Darrin Fink did it on his Mog:

1. dwh's First Private Message

dwh then supplemented the above post with an additional private message:

I remembered something I meant to mention. I didn't mention it because it was on the high altitude thread, and I thought it properly belonged on the heavy truck thread [see post #83, at http://www.expeditionportal.com/for...EST-High-Altitude-Solution-for-Heating/page9].

You said something to the effect of the engine in Ivan must be a pusher because otherwise it would be in the way of the entry door/stairway.

This is not exactly correct. I don't doubt that Ivan is a pusher, though as big as it is, it would be no problem to place the engine under the floor.

But in the U.S., we have a company that makes buses - Bluebird. They have for many years produced flat-nosed front engine buses (and motorhomes). The trick is simply to angle the stairs to the rear a bit:

http://www.bargainbusnews.com/Buses/...dTC-2000-1.jpg

Cheers.

2. biotect's Reply to dwh

To which I responded privately as follows. The first half:

dwh,

Many thanks for this!!! I had simply assumed that the COE format was largely incompatible with broad, deeply embedded entrance staircases up front. One can have such a staircase in the middle of a large vehicle that's COE, sure, but not up front. Or so I thought. Most European tour buses that have such deeply embedded staircases up front, for instance, are pusher-diesel designs. And so too, in the United States the better Class-A motorhomes will have pusher-diesel engines; the expensive ones are usually based on a Prevost "pusher" bus chassis. As such, the better Class-A motorhomes will have no problem providing very generous entrance staircases.

This link then helps me tremendously, because I was actually favoring a COE design, and not a pusher-diesel design. If you've had time to read the "Fully Integrated MAN or Tatra" thread, you might have seen that egn and I engaged in a bit of a debate at the beginning regarding COE, versus Pusher, versus CBE. The main reason I favored either COE or CBE, is because I wanted the motorhome to have a big drop-down deck in back, with a living room opening out onto the deck, "cottage style". With full-height sliding-glass-doors, as per the sliding-glass-doors that open onto Country Coach's "Verandah", or the rear deck of Knaus-Tabbert's "Caravisio". Or similar to the rear deck and sliding-glass-doors of Rob Gray's Wothahellizat -- see posts #139 - #141, at http://www.expeditionportal.com/foru...e-Frame/page14 and http://www.expeditionportal.com/foru...e-Frame/page15 .

The Wothahellizat truck is on the borderline between CBE and COE, with a very short, snub-nosed bonnet -- see post #142, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page15 . Because engine access is from the front, by lifting the very short bonnet, the Wothahellizat's cab does not need to tilt forward as per most COE designs. The Wothahellizat can then have a huge "alcove" cantilevered over the cab, as well as a big, drop-down deck in the back.

But unless the rear pusher-diesel engine were really "flat", as per the engine in the UFO chassis that was available for a while, a rear deck would not be possible with a pusher diesel blocking things. See post # 116, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page12 . Most Class-A "pusher" motorhomes will have a big bed in back, sitting on top of a box that camouflages the pusher diesel engine.

Ergo, I tended to favor COE instead. Except that entry to the cabs of COE vehicles tends to be more challenging, especially if they are "flat floor" COE cabs. See for instance my post about the Mercedes Actros "GigaSpace" flat-floor cab, #283, at http://www.expeditionportal.com/foru...e-Frame/page29 . If you watch the videos of the Mercedes Actros trucks in that post, it's clear that one has to first ascend a vertical ladder of of steps outside the vehicle, in order to gain access to the cab. This is fairly typical of big trucks in Europe that are COE. So I was really surprised and pleased to see that photo of the Bluebird bus, with a more easily ascendable embedded interior staircase, compatible with COE engine placement.

In other words, it would be terrific to be able to have both COE and a very generous, deeply embedded entrance staircase, as per Ivan the Terrabus.....

Please see how I changed the post about Ivan the Terrabus' entrance staircase in the "High Altitude Heating " thread, after I got your message above -- for reference, it was post #83, at http://www.expeditionportal.com/foru...-Heating/page9 . And please, if you come across any other mistaken assumptions, do feel free to write me and correct me, either by private email, or directly in a thread. I really appreciate the feedback!

The second half:

Of course, everything changes once one abandons the assumption of an ICE, and moves to a hybrid microturbine instead.

The microturbine itself would be much smaller than an ICE, and as egn suggested earlier in the thread, the batteries could be "distributed" elsewhere in the vehicle. So this completely opens up the cab design, and makes a very generous, wide, deeply embedded entrance staircase possible, even in COE placement. On the other hand, if instead the microturbine were located in back, it would be much smaller and squatter than a big diesel ICE, and so would also prove compatible with a living room directly above it, opening out onto a rear deck, as per Rob Gray's Wothahellizat.

Now I wonder where, from a purely mechanical or engineering point of view, a microturbine would best locate? Up front, or in back? The New York pilot project buses by DesignLine that were fitted with Capstone turbines had them located in back, and from the point of view of noise this might make the most sense. But although Capstone insists that their microturbines do not need a radiator at the front of the vehicle, they still do need good incoming and outgoing ventilation, right? They are turbines after all. All of the other turbines I've seen fitted in vehicles had generous air intakes. So perhaps front is best, as per the placement of a Capstone C65 in the Peterbilt concept truck?

On the other hand, there is the noise factor, and the Capstone CMT-380 sports car is very noisy when the microturbine is running. Which makes rear placement more attractive again.

What do you think?

3. dwh's Second Private Message

Here was dwh's reply:

With a Tatra chassis, which does not flex, you have the entire space between the frame rails and above the transaxle available. I would think that would be a very nice place for a gigantic battery bank - and the majority of the weight would be *below* the frame rails (ballast). Also, very well protected by the transaxle. The space outside the frame rails, between the front and rear axles would seem to be a good place to locate the turbine(s). Easily accessible for service. But soundproof it and duct the intake/exhaust to the roof to blow both heat and sound out and up away from the neighbors, who love to ********** about generator (and air conditioner and watermaker) noise.

Alternately, perhaps only have the battery bank in the rear, and locate the generating plant between the frame rails under the cab. The Tatra cab tilts, but you would lose that advantage with an integrated design.

Another plus of the Tatra design, is that the transaxle has a single power input point, which would make it easy to construct a combined inline unit consisting of motor/torque converter/gear box (say 1.5:1 OD, 1:1 and 2:1 (low range))/regenerative braking system (use the clutch pedal to control the field of a massive alternator and there's your regen system - while still retaining the air brake system). You could probably engineer that combined unit to just drop in between the frame rails. In which case, you could probably (or at least, mostly) eliminate the doghouse in the cab, for a flat floor.

In any case, you have to make your embedded steps fit *outside* the frame rails.

You could make the center section of floor able to be lifted out, and have access from above. Design a side hatch, so that the seats could be removed (creating a workshop space), the center section of the floor lifted out, and then open the hatch, run in the cherry picker (engine hoist) and lift out the entire generator plant or powertrain unit. You might be able to do it through the door, but I think it would be tight.

OR, put everything on a slide out the front, similar to the way they do generators on some of the larger motorhomes:

http://www.rvst.org/candidate/Images/Gen7.png

Open the floor up, disconnect a few bits here and there, and then just slide the whole works out. You could probably rig it so the battery bank slides out the rear as well.

Or use Tesla batteries.

http://www.teslamotors.com/batteryswap

Cheers

And here is the image:

On my own view dwh's third proposal for a front-accessible "pull out" microturbine generator, mounted on a tray, is simply brilliant. At one stroke this solves a problem that has been vexing me for most of this thread: that COE placement with a tilting cab undermines the possibility of a fully integrated design.

Recall that this problem was discussed at considerable length earlier in the thread -- see posts #110 - #114 , #119 - #120 - #127 , at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page11 , http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page12 , and http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page13 (standard ExPo pagination). See especially egn's deft summary of the various disadvantages of different kinds of engine placement on page 13, post #127, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page13 .

A fully integrated design seems only genuinely compatible with either:

(a) "Pusher" engine placement, allowing easy access to the engine at the back of the vehicle.

or

(b) CBE placement, allowing easy access to the engine by lifting the bonnet, as per Earthroamer and Tiger expedition vehicles, or Rob Gray's short-bonnet Wothahellizat.

or

(c) COE placement, via a lid inside the cab that opens up the engine tunnel.

The first pusher solution for an ICE engine is not desirable from my "design" point of view, because as explained in the first half of my reply to dwh, I want the vehicle to have a large drop-down deck in back, akin to Rob Gray's Wothahellizat. And a "pusher" engine placement in back would make that impossible.

Next, although I am personally not dead-set against the second CBE solution, many participants early on in the thread disliked it immensely, including grizzlyj and egn. They did not want a bonnet, no matter how short, compromising forward visibility of the terrain.

The third solution, access to the engine from inside the vehicle, has been instantiated in a number of fully integrated designs. See for instance: (1) Autobus Australia's "Tonto" off-road, all-terrain bus -- post #209, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page21 ; (2) Peter Thompson's Mañana "bad-road" motorhome -- post #212 at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page22 ; and (3) the Deco-Liner -- post #166 at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page17 .

However, in response to the last post, egn wrote:

There are a lot of (older) trucks that have engine access from inside the cab. But I wouldn't want that in a luxury vehicle, because I don't like when truck mechanics work inside the vehicle. You always then have the risk that something gets damaged, dirty and you also get the diesel and oil smell into your cabin.

So the third solution does not seem that attractive either, even though it's the solution that seems most compatible with a fully integrated design that is COE, and that would have a drop-down deck in back.

But everything changes if the engine is a range-extending microturbine, driving a generator. To begin with, ICE range-extenders that are only hooked up to generators are already much lighter than engines directly powering a vehicle's wheels. And for the same amount of power output, a microturbine genset is lighter still and more compact than an ICE. So as dwh suggests, a microturbine genset could be placed COE, but on a forward-sliding tray, thereby providing full 360-degree engine access for service, and eliminating any need to tilt the cab.

Again, this solves a basic design conundrum that has been vexing me for most of this thread, and I can't thank dwh enough for this brilliant, very simple, but perhaps not obvious solution.

This is also a solution that allows for the possibility of a very generously proportioned, deeply "embedded" entrance staircase, as per Ivan the Terrabus. As explained to dwh in my reply, another disadvantage of many COE truck designs is that one has to climb a vertical "step ladder" outside the vehicle in order to gain access to the cab. The bigger the ICE underneath, and the flatter the floor of the cab, the higher the climb. Whereas although a microturbine placed COE would still take up space, it would not take up nearly as much space as a powerful ICE. A microturbine (or even two microturbines, plural, for redundancy) would not be nearly as high. And so a flat-cab-floor -- which is a kind of "motorhome ideal", and also an ideal for COE truckers -- could be much lower. And a Terrabus-style broad and deep entrance staircase would be no problem at all.

I will address the other suggestions in dwh's second private message later in the thread, from post # 503 onwards -- see http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page51 .

**************************************

CONTINUED IN NEXT POST

.

Last edited:

biotect

Designer

.

CONTINUED FROM PREVIOUS POST

**************************************

Here is the sequence again, but this time supplemented by additional information and images to round out the content

1. dwh's First Private Message

Here is the image:

As near as I can tell, Bluebird no longer makes motorhomes (?), although it still does make buses. And many of these buses have very low and broad front entryway staircases, even though they have engines located in front, as made possible by the Bluebird Y3 Chassis -- see http://en.wikipedia.org/wiki/Blue_Bird_Corporation , http://en.wikipedia.org/wiki/Blue_Bird_Wanderlodge , http://www.blue-bird.com/all-american-fe-diesel.aspx , http://www.blue-bird.com/all-american-product-literature.aspx , http://www.blue-bird.com/sigma-transit-bus.aspx , http://www.blue-bird.com/global-bus-market.aspx , http://www.blue-bird.com/specialty-buses.aspx , http://www.blue-bird.com/product-literature.aspx#.U_xVdHmSf6k , and http://www.blue-bird.com/global-product-literature.aspx :

Most of the buses on the Bluebird website seem to be either CBE or Pushers. But a significant number are "fully integrated" COE designs, in which engine access is from the front of the bus, as well as from inside, by lifting a lid on the engine tunnel:

As dwh rightly points out in his first private message, this is perfectly compatible with a wide and rather deep entrance staircase, in Bluebird's Sigma FE diesel transit bus, as well as its All-American RE school bus:

**************************************

CONTINUED IN NEXT POST

CONTINUED FROM PREVIOUS POST

**************************************

Here is the sequence again, but this time supplemented by additional information and images to round out the content

1. dwh's First Private Message

I remembered something I meant to mention. I didn't mention it because it was on the high altitude thread, and I thought it properly belonged on the heavy truck thread [see post #83, at http://www.expeditionportal.com/for...EST-High-Altitude-Solution-for-Heating/page9].

You said something to the effect of the engine in Ivan must be a pusher because otherwise it would be in the way of the entry door/stairway.

This is not exactly correct. I don't doubt that Ivan is a pusher, though as big as it is, it would be no problem to place the engine under the floor.

But in the U.S., we have a company that makes buses - Bluebird. They have for many years produced flat-nosed front engine buses (and motorhomes). The trick is simply to angle the stairs to the rear a bit:

http://www.bargainbusnews.com/Buses/...dTC-2000-1.jpg

Cheers.

Here is the image:

As near as I can tell, Bluebird no longer makes motorhomes (?), although it still does make buses. And many of these buses have very low and broad front entryway staircases, even though they have engines located in front, as made possible by the Bluebird Y3 Chassis -- see http://en.wikipedia.org/wiki/Blue_Bird_Corporation , http://en.wikipedia.org/wiki/Blue_Bird_Wanderlodge , http://www.blue-bird.com/all-american-fe-diesel.aspx , http://www.blue-bird.com/all-american-product-literature.aspx , http://www.blue-bird.com/sigma-transit-bus.aspx , http://www.blue-bird.com/global-bus-market.aspx , http://www.blue-bird.com/specialty-buses.aspx , http://www.blue-bird.com/product-literature.aspx#.U_xVdHmSf6k , and http://www.blue-bird.com/global-product-literature.aspx :

Most of the buses on the Bluebird website seem to be either CBE or Pushers. But a significant number are "fully integrated" COE designs, in which engine access is from the front of the bus, as well as from inside, by lifting a lid on the engine tunnel:

As dwh rightly points out in his first private message, this is perfectly compatible with a wide and rather deep entrance staircase, in Bluebird's Sigma FE diesel transit bus, as well as its All-American RE school bus:

**************************************

CONTINUED IN NEXT POST

Last edited:

biotect

Designer

.

CONTINUED FROM PREVIOUS POST

**************************************

Some more images of the Bluebird Sigma FE diesel transit bus:

2. biotect's reply to dwh

Again, here is the first half of my response to dwh:

**********************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

**************************************

Some more images of the Bluebird Sigma FE diesel transit bus:

2. biotect's reply to dwh

Again, here is the first half of my response to dwh:

dwh,

Many thanks for this!!! I had simply assumed that the COE format was largely incompatible with broad, deeply embedded entrance staircases up front. One can have such a staircase in the middle of a large vehicle that's COE, sure, but not up front. Or so I thought. Most European tour buses that have such deeply embedded staircases up front, for instance, are pusher-diesel designs. And so too, in the United States the better Class-A motorhomes will have pusher-diesel engines; the expensive ones are usually based on a Prevost "pusher" bus chassis. As such, the better Class-A motorhomes will have no problem providing very generous entrance staircases.

This link then helps me tremendously, because I was actually favoring a COE design, and not a pusher-diesel design. If you've had time to read the "Fully Integrated MAN or Tatra" thread, you might have seen that egn and I engaged in a bit of a debate at the beginning regarding COE, versus Pusher, versus CBE. The main reason I favored either COE or CBE, is because I wanted the motorhome to have a big drop-down deck in back, with a living room opening out onto the deck, "cottage style". With full-height sliding-glass-doors, as per the sliding-glass-doors that open onto Country Coach's "Verandah", or the rear deck of Knaus-Tabbert's "Caravisio". Or similar to the rear deck and sliding-glass-doors of Rob Gray's Wothahellizat -- see posts #139 - #141, at http://www.expeditionportal.com/foru...e-Frame/page14 and http://www.expeditionportal.com/foru...e-Frame/page15 .

The Wothahellizat truck is on the borderline between CBE and COE, with a very short, snub-nosed bonnet -- see post #142, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page15 . Because engine access is from the front, by lifting the very short bonnet, the Wothahellizat's cab does not need to tilt forward as per most COE designs. The Wothahellizat can then have a huge "alcove" cantilevered over the cab, as well as a big, drop-down deck in the back.

But unless the rear pusher-diesel engine were really "flat", as per the engine in the UFO chassis that was available for a while, a rear deck would not be possible with a pusher diesel blocking things. See post # 116, at http://www.expeditionportal.com/for...pedition-RV-w-Rigid-Torsion-Free-Frame/page12 . Most Class-A "pusher" motorhomes will have a big bed in back, sitting on top of a box that camouflages the pusher diesel engine.

Ergo, I tended to favor COE instead. Except that entry to the cabs of COE vehicles tends to be more challenging, especially if they are "flat floor" COE cabs. See for instance my post about the Mercedes Actros "GigaSpace" flat-floor cab, #283, at http://www.expeditionportal.com/foru...e-Frame/page29 . If you watch the videos of the Mercedes Actros trucks in that post, it's clear that one has to first ascend a vertical ladder of of steps outside the vehicle, in order to gain access to the cab. This is fairly typical of big trucks in Europe that are COE. So I was really surprised and pleased to see that photo of the Bluebird bus, with a more easily ascendable embedded interior staircase, compatible with COE engine placement.

In other words, it would be terrific to be able to have both COE and a very generous, deeply embedded entrance staircase, as per Ivan the Terrabus.....

Please see how I changed the post about Ivan the Terrabus' entrance staircase in the "High Altitude Heating " thread, after I got your message above -- for reference, it was post #83, at http://www.expeditionportal.com/foru...-Heating/page9 . And please, if you come across any other mistaken assumptions, do feel free to write me and correct me, either by private email, or directly in a thread. I really appreciate the feedback!

**********************************

CONTINUED IN NEXT POST

.

Last edited:

biotect

Designer

.

CONTINUED FROM PREVIOUS POST

*************************************

Some Background Material about Capstone Microturbines in Automotive Hybrid Applications

**************************************

And here is the second half of my response to dwh:

A. New York Pilot Project Buses fitted with Capstone Turbines

The background behind the "New York pilot project buses" is the following.

Over the years Capstone has worked with a variety of bus manufacturers, hoping to see its microturbines adopted as part of a serial hybrid solution, with varying degrees of success. For instance, in the early 2000's Capstone worked with the (now bankrupt) “Advanced Vehicle Systems” (AVS) of Chattanooga, Tennessee to create hybrid buses for transit use – see http://www.microturbine.com/news/story.asp?id=7 , http://www.capstoneturbine.com/news/story.asp?id=66 , http://www.highbeam.com/doc/1G1-20357308.html , http://www.highbeam.com/doc/1G1-97315524.html, http://www.highbeam.com/doc/1G1-83562752.html , and https://www.sce.com/NR/rdonlyres/40...1ED6CF67/0/ElectricTransportationSCEVol72.pdf .

Until relatively recently, DesignLine, of New Zealand and Charlotte North Carolina, seemed to be having much better success selling microturbine-equipped buses, while remaining solvent – see http://en.wikipedia.org/wiki/Gas_turbine#Buses , http://www.nzine.co.nz/views/designline_3.html , http://www.microturbine.com/news/story.asp?id=460 , http://thefraserdomain.typepad.com/energy/2008/04/designline-orde.html , http://www.bizjournals.com/losangeles/stories/2008/03/31/daily29.html , http://www.greencarcongress.com/2008/04/capstone-turbin.html , and http://nccleantech.ncsu.edu/wp-content/uploads/DesignLine-Presentation-for-4.12.2012.pdf .

Beginning in 2007, New York tested five Design Line serial-hybrid buses for 18 months, buses fitted with Capstone microturbines as range-extenders. The microturbines were located at the back of the bus, as per the engine placement of a diesel "pusher":

See http://www.capstoneturbine.com/prodsol/solutions/hev.asp and http://www.capstoneturbine.com/_docs/CAP1100_Drive Solution_Range Extender_LR.pdf for further description of Capstone's "Range Extender" drive solution.

These buses were popular with riders, because when driving under electric power they were so quiet – see http://green.autoblog.com/2007/10/1...it-authority-testing-micro-turbine-hybrid-bu/ , http://www.nytimes.com/2009/12/07/nyregion/07bus.html?_r=0 , http://coolvehiclesotherthings.weebly.com/capstone-turbine-power.html , http://www.futurecars.com/news/hybrid-cars/turbine-powered-hybrid-electric-buses-on-new-york-streets , and http://www.ecofriend.com/eco-buses-designline-hybrid-electric-bus-is-as-quiet-as-a-tomb.html . The following videos demonstrate just how quiet, even with the microturbine running. The first video is a very useful "compilation" that seems to include the same footage as most of the other, shorter clips on YouTube. But I've also included a few of the shorter clips as well:

[video=youtube;PIwl-MazbcI]http://www.youtube.com/watch?v=PIwl-MazbcI [/video]

[video=youtube;8lofVW-OB88]http://www.youtube.com/watch?v=8lofVW-OB88 [/video]

[video=youtube;g2fzsvnK8Vw]https://www.youtube.com/watch?v=g2fzsvnK8Vw [/video] [video=youtube;HigkzcRWWUU]http://www.youtube.com/watch?v=HigkzcRWWUU [/video]

[video=youtube;4vLjr43B-1w]http://www.youtube.com/watch?v=4vLjr43B-1w [/video] [video=youtube;T2lHU88agp0]http://www.youtube.com/watch?v=T2lHU88agp0 [/video]

Also see http://www.youtube.com/watch?v=HYo74wrja2Y , http://www.youtube.com/watch?v=BCydG1xlu2I , http://www.youtube.com/watch?v=f_Msa0pTC9k , http://www.youtube.com/watch?v=MNEvfywAkVY , https://www.youtube.com/watch?v=N9nhlmGEA7M , https://www.youtube.com/watch?v=ztN5_TrUiAo , https://www.youtube.com/watch?v=QdJg1reYGDw , and https://www.youtube.com/watch?v=f_Msa0pTC9k .

Notice the high-frequency but not very loud sound that the microturbine makes.

Inside the buses, the Capstone microturbine is barely audible:

[video=youtube;iH300EAVQTY]http://www.youtube.com/watch?v=iH300EAVQTY [/video] [video=youtube;9W4bx_O_hjo]http://www.youtube.com/watch?v=9W4bx_O_hjo [/video]

Also see http://www.youtube.com/watch?v=E-C-ihNItVQ , http://www.youtube.com/watch?v=-MDQAUEgrTU , https://www.youtube.com/watch?v=-MtoEIqE1cU , https://www.youtube.com/watch?v=dab8O_tbfOw&feature=channel , http://www.youtube.com/watch?v=wjzMz34IzOs , and https://www.youtube.com/watch?v=IucIWrxbkm0 .

However, the New York Transit Authority found that these DesignLine buses were underpowered, and not sufficiently reliable:

See http://www.greencarreports.com/news...bine-hybrid-buses-not-up-to-nyc-service-sadly and http://secondavenuesagas.com/2011/02/03/end-of-the-designline-for-new-buses/ .

Apparently Baltimore came to the same conclusion, and after New York cancelled a potential order for 87 additional buses, the future of DesignLine became uncertain – see http://www.bizjournals.com/charlott...ignline-losing-a-major-contract.html?page=all , http://www.bizjournals.com/charlott...-designline-ceo-shift-solve-one.html?page=all , http://www.bizjournals.com/charlott...ntract-dispute-drive-designline.html?page=all , and http://secondavenuesagas.com/2012/03/19/former-mta-bus-head-named-designline-interim-ceo/ . Like AVS before it, DesignLine has since gone bankrupt, but in 2013 its assets were bought be a group of California investors, who renamed it "Environmental Performance Vehicles" -- see http://en.wikipedia.org/wiki/Environmental_Performance_Vehicles and http://epvinc.com .

More about AVS and DesignLine later in the thread....

**********************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

*************************************

Some Background Material about Capstone Microturbines in Automotive Hybrid Applications

**************************************

And here is the second half of my response to dwh:

Of course, everything changes once one abandons the assumption of an ICE, and moves to a hybrid microturbine instead.

The microturbine itself would be much smaller than an ICE, and as egn suggested earlier in the thread, the batteries could be "distributed" elsewhere in the vehicle. So this completely opens up the cab design, and makes a very generous, wide, deeply embedded entrance staircase possible, even in COE placement. On the other hand, if instead the microturbine were located in back, it would be much smaller and squatter than a big diesel ICE, and so would also prove compatible with a living room directly above it, opening out onto a rear deck, as per Rob Gray's Wothahellizat.

Now I wonder where, from a purely mechanical or engineering point of view, a microturbine would best locate? Up front, or in back? The New York pilot project buses by DesignLine that were fitted with Capstone turbines had them located in back, and from the point of view of noise this might make the most sense. But although Capstone insists that their microturbines do not need a radiator at the front of the vehicle, they still do need good incoming and outgoing ventilation, right? They are turbines after all. All of the other turbines I've seen fitted in vehicles had generous air intakes. So perhaps front is best, as per the placement of a Capstone C65 in the Peterbilt concept truck?

On the other hand, there is the noise factor, and the Capstone CMT-380 sports car is very noisy when the microturbine is running. Which makes rear placement more attractive again.

What do you think?

A. New York Pilot Project Buses fitted with Capstone Turbines

The background behind the "New York pilot project buses" is the following.

Over the years Capstone has worked with a variety of bus manufacturers, hoping to see its microturbines adopted as part of a serial hybrid solution, with varying degrees of success. For instance, in the early 2000's Capstone worked with the (now bankrupt) “Advanced Vehicle Systems” (AVS) of Chattanooga, Tennessee to create hybrid buses for transit use – see http://www.microturbine.com/news/story.asp?id=7 , http://www.capstoneturbine.com/news/story.asp?id=66 , http://www.highbeam.com/doc/1G1-20357308.html , http://www.highbeam.com/doc/1G1-97315524.html, http://www.highbeam.com/doc/1G1-83562752.html , and https://www.sce.com/NR/rdonlyres/40...1ED6CF67/0/ElectricTransportationSCEVol72.pdf .

Until relatively recently, DesignLine, of New Zealand and Charlotte North Carolina, seemed to be having much better success selling microturbine-equipped buses, while remaining solvent – see http://en.wikipedia.org/wiki/Gas_turbine#Buses , http://www.nzine.co.nz/views/designline_3.html , http://www.microturbine.com/news/story.asp?id=460 , http://thefraserdomain.typepad.com/energy/2008/04/designline-orde.html , http://www.bizjournals.com/losangeles/stories/2008/03/31/daily29.html , http://www.greencarcongress.com/2008/04/capstone-turbin.html , and http://nccleantech.ncsu.edu/wp-content/uploads/DesignLine-Presentation-for-4.12.2012.pdf .

Beginning in 2007, New York tested five Design Line serial-hybrid buses for 18 months, buses fitted with Capstone microturbines as range-extenders. The microturbines were located at the back of the bus, as per the engine placement of a diesel "pusher":

See http://www.capstoneturbine.com/prodsol/solutions/hev.asp and http://www.capstoneturbine.com/_docs/CAP1100_Drive Solution_Range Extender_LR.pdf for further description of Capstone's "Range Extender" drive solution.

These buses were popular with riders, because when driving under electric power they were so quiet – see http://green.autoblog.com/2007/10/1...it-authority-testing-micro-turbine-hybrid-bu/ , http://www.nytimes.com/2009/12/07/nyregion/07bus.html?_r=0 , http://coolvehiclesotherthings.weebly.com/capstone-turbine-power.html , http://www.futurecars.com/news/hybrid-cars/turbine-powered-hybrid-electric-buses-on-new-york-streets , and http://www.ecofriend.com/eco-buses-designline-hybrid-electric-bus-is-as-quiet-as-a-tomb.html . The following videos demonstrate just how quiet, even with the microturbine running. The first video is a very useful "compilation" that seems to include the same footage as most of the other, shorter clips on YouTube. But I've also included a few of the shorter clips as well:

[video=youtube;PIwl-MazbcI]http://www.youtube.com/watch?v=PIwl-MazbcI [/video]

[video=youtube;8lofVW-OB88]http://www.youtube.com/watch?v=8lofVW-OB88 [/video]

[video=youtube;g2fzsvnK8Vw]https://www.youtube.com/watch?v=g2fzsvnK8Vw [/video] [video=youtube;HigkzcRWWUU]http://www.youtube.com/watch?v=HigkzcRWWUU [/video]

[video=youtube;4vLjr43B-1w]http://www.youtube.com/watch?v=4vLjr43B-1w [/video] [video=youtube;T2lHU88agp0]http://www.youtube.com/watch?v=T2lHU88agp0 [/video]

Also see http://www.youtube.com/watch?v=HYo74wrja2Y , http://www.youtube.com/watch?v=BCydG1xlu2I , http://www.youtube.com/watch?v=f_Msa0pTC9k , http://www.youtube.com/watch?v=MNEvfywAkVY , https://www.youtube.com/watch?v=N9nhlmGEA7M , https://www.youtube.com/watch?v=ztN5_TrUiAo , https://www.youtube.com/watch?v=QdJg1reYGDw , and https://www.youtube.com/watch?v=f_Msa0pTC9k .

Notice the high-frequency but not very loud sound that the microturbine makes.

Inside the buses, the Capstone microturbine is barely audible:

[video=youtube;iH300EAVQTY]http://www.youtube.com/watch?v=iH300EAVQTY [/video] [video=youtube;9W4bx_O_hjo]http://www.youtube.com/watch?v=9W4bx_O_hjo [/video]

Also see http://www.youtube.com/watch?v=E-C-ihNItVQ , http://www.youtube.com/watch?v=-MDQAUEgrTU , https://www.youtube.com/watch?v=-MtoEIqE1cU , https://www.youtube.com/watch?v=dab8O_tbfOw&feature=channel , http://www.youtube.com/watch?v=wjzMz34IzOs , and https://www.youtube.com/watch?v=IucIWrxbkm0 .

However, the New York Transit Authority found that these DesignLine buses were underpowered, and not sufficiently reliable:

…the TA said that the 30-kilowatt (40-horsepower) turbine generators didn't "provide enough power to operate in regular passenger service in a multitude of conditions."

DesignLine subsequently fitted a much larger 65-kW (87-hp) turbine to one of the test buses, but the TA said it wasn't sufficiently reliable. It has now ended the test, returned the test buses to DesignLine, and is getting a refund on the money it spent on the tests.

See http://www.greencarreports.com/news...bine-hybrid-buses-not-up-to-nyc-service-sadly and http://secondavenuesagas.com/2011/02/03/end-of-the-designline-for-new-buses/ .

Apparently Baltimore came to the same conclusion, and after New York cancelled a potential order for 87 additional buses, the future of DesignLine became uncertain – see http://www.bizjournals.com/charlott...ignline-losing-a-major-contract.html?page=all , http://www.bizjournals.com/charlott...-designline-ceo-shift-solve-one.html?page=all , http://www.bizjournals.com/charlott...ntract-dispute-drive-designline.html?page=all , and http://secondavenuesagas.com/2012/03/19/former-mta-bus-head-named-designline-interim-ceo/ . Like AVS before it, DesignLine has since gone bankrupt, but in 2013 its assets were bought be a group of California investors, who renamed it "Environmental Performance Vehicles" -- see http://en.wikipedia.org/wiki/Environmental_Performance_Vehicles and http://epvinc.com .

More about AVS and DesignLine later in the thread....

**********************************

CONTINUED IN NEXT POST

.

Last edited:

biotect

Designer

.

CONTINUED FROM PREVIOUS POST

**************************************

B. Trucks fitted with Capstone Turbines

Capstone turbines have also been fitted into medium-sized trucks, for instance, by Wrightspeed:

[video=youtube;Bi5RqBuVNcc]https://www.youtube.com/watch?v=Bi5RqBuVNcc [/video]

See http://wrightspeed.com , http://wrightspeed.com/products/the-route/ , http://wrightspeed.com/news/ , and http://wrightspeed.com/about/ .

In 2011, Capstone announced that it would team up with a very large Truck OEM, the name of the OEM kept secret. Turns out that it was Peterbilt, in partnership with Walmart and Great Dane trailers. Together they created a radically new concept truck fitted with a microturbine:

[video=youtube;iTTgxqZqTaA]https://www.youtube.com/watch?v=iTTgxqZqTaA&feature=youtu.be [/video]

Here are some excerpts from the Summer 2010 edition of Capstone's "Turbine Talk" newsletter, which explain some of Capstone's more recent initiatives in HEV's:

See www.capstoneturbine.com/news/turbineTalkDL.asp?id=5 .

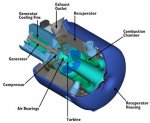

The following is a short pdf that describes Capstone's range-extender drive solution, along with some additional cut-way images of Capstone's solution installed in a truck -- see http://www.capstoneturbine.com/prodsol/products/ , http://www.capstoneturbine.com/prodsol/solutions/hev.asp , and http://www.capstoneturbine.com/_docs/CAP1100_Drive Solution_Range Extender_LR.pdf:

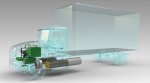

And this is more schematic material about the Walmart/Peterbilt/Capstone concept truck, available on Walmart's website. The first describes the different operational modes of the truck:

**************************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

**************************************

B. Trucks fitted with Capstone Turbines

Capstone turbines have also been fitted into medium-sized trucks, for instance, by Wrightspeed:

[video=youtube;Bi5RqBuVNcc]https://www.youtube.com/watch?v=Bi5RqBuVNcc [/video]

See http://wrightspeed.com , http://wrightspeed.com/products/the-route/ , http://wrightspeed.com/news/ , and http://wrightspeed.com/about/ .

In 2011, Capstone announced that it would team up with a very large Truck OEM, the name of the OEM kept secret. Turns out that it was Peterbilt, in partnership with Walmart and Great Dane trailers. Together they created a radically new concept truck fitted with a microturbine:

[video=youtube;iTTgxqZqTaA]https://www.youtube.com/watch?v=iTTgxqZqTaA&feature=youtu.be [/video]

Here are some excerpts from the Summer 2010 edition of Capstone's "Turbine Talk" newsletter, which explain some of Capstone's more recent initiatives in HEV's:

See www.capstoneturbine.com/news/turbineTalkDL.asp?id=5 .

The following is a short pdf that describes Capstone's range-extender drive solution, along with some additional cut-way images of Capstone's solution installed in a truck -- see http://www.capstoneturbine.com/prodsol/products/ , http://www.capstoneturbine.com/prodsol/solutions/hev.asp , and http://www.capstoneturbine.com/_docs/CAP1100_Drive Solution_Range Extender_LR.pdf:

And this is more schematic material about the Walmart/Peterbilt/Capstone concept truck, available on Walmart's website. The first describes the different operational modes of the truck:

**************************************

CONTINUED IN NEXT POST

.

Last edited:

biotect

Designer

.

CONTINUED FROM PREVIOUS POST

**************************************

Here are some good exterior images of the Walmart/Peterbilt/Capstone concept truck, plus a view of the engine compartment. Notice how comparatively low the truck's cab-floor is, and yet it is perfectly flat, not obstructed by an engine tunnel or "dog-house":

More interior images to follow, later in the thread.

See http://news.walmart.com/news-archive/2014/03/26/walmart-debuts-futuristic-truck , http://corporate.walmart.com/truck , http://blog.walmart.com/the-future-of-fleet-efficiency ,http://blog.walmart.com/notes-from-the-milestone-meeting , http://news.walmart.com/media-library/photos/logistics-truck-fleet/ , http://news.walmart.com/photos/wave?context=overlay&checkImageOrientation=true , http://news.walmart.com/photos/walm...or?context=overlay&checkImageOrientation=true , http://news.walmart.com/photos/walm...ic?context=overlay&checkImageOrientation=true , http://fleetowner.com/equipment/walmart-advanced-vehicle-experience-concept-rig , http://fleetowner.com/running-green/walmart-rolls-out-futuristic-fuel-saving-rig , http://www.fleetequipmentmag.com/trending-truck-equipment-tracking-hottest-industry-trends/ , http://www.businessinsider.com.au/walmarts-truck-of-the-future-2014-3 , http://www.pedal.ir/خو&...575;لمارت-wave/ , http://forwardthinking.pcmag.com/none/324498-walmart-vehicle-is-a-truck-worth-staring-at , http://designer.ge/walmart-truck/ , http://blog.caranddriver.com/walmar...-big-rig-of-the-future-w-photo-gallery-video/ , http://galleryhip.com/new-walmart-trucks-interior.html , http://www.livetrucking.com/walmart-concept-truck/ , https://cricket.yahoo.com/photos/wa...w/wave-truck-concept-photo-1393885382188.html , http://www.theblaze.com/stories/201...s-to-use-to-maximize-efficiency-on-the-road/# , http://www.geek.com/news/this-is-walmarts-futuristic-turbine-powered-wave-big-rig-1596687/ , http://gomotors.net/car-reviews/Peterbilt-Turbine_Hybrid-Big-Rig/ , and http://www.veooz.com/photos/vH1IVvo.html .

**************************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

**************************************

Here are some good exterior images of the Walmart/Peterbilt/Capstone concept truck, plus a view of the engine compartment. Notice how comparatively low the truck's cab-floor is, and yet it is perfectly flat, not obstructed by an engine tunnel or "dog-house":

More interior images to follow, later in the thread.

See http://news.walmart.com/news-archive/2014/03/26/walmart-debuts-futuristic-truck , http://corporate.walmart.com/truck , http://blog.walmart.com/the-future-of-fleet-efficiency ,http://blog.walmart.com/notes-from-the-milestone-meeting , http://news.walmart.com/media-library/photos/logistics-truck-fleet/ , http://news.walmart.com/photos/wave?context=overlay&checkImageOrientation=true , http://news.walmart.com/photos/walm...or?context=overlay&checkImageOrientation=true , http://news.walmart.com/photos/walm...ic?context=overlay&checkImageOrientation=true , http://fleetowner.com/equipment/walmart-advanced-vehicle-experience-concept-rig , http://fleetowner.com/running-green/walmart-rolls-out-futuristic-fuel-saving-rig , http://www.fleetequipmentmag.com/trending-truck-equipment-tracking-hottest-industry-trends/ , http://www.businessinsider.com.au/walmarts-truck-of-the-future-2014-3 , http://www.pedal.ir/خو&...575;لمارت-wave/ , http://forwardthinking.pcmag.com/none/324498-walmart-vehicle-is-a-truck-worth-staring-at , http://designer.ge/walmart-truck/ , http://blog.caranddriver.com/walmar...-big-rig-of-the-future-w-photo-gallery-video/ , http://galleryhip.com/new-walmart-trucks-interior.html , http://www.livetrucking.com/walmart-concept-truck/ , https://cricket.yahoo.com/photos/wa...w/wave-truck-concept-photo-1393885382188.html , http://www.theblaze.com/stories/201...s-to-use-to-maximize-efficiency-on-the-road/# , http://www.geek.com/news/this-is-walmarts-futuristic-turbine-powered-wave-big-rig-1596687/ , http://gomotors.net/car-reviews/Peterbilt-Turbine_Hybrid-Big-Rig/ , and http://www.veooz.com/photos/vH1IVvo.html .

**************************************

CONTINUED IN NEXT POST

.

Last edited:

Similar threads

- Replies

- 74

- Views

- 38K

- Replies

- 20

- Views

- 7K

- Replies

- 1

- Views

- 1K

- Replies

- 202

- Views

- 149K

- Replies

- 39

- Views

- 50K