biotect

Designer

.

CONTINUED FROM PREVIOUS POST

*******************************************

There is also clearly the possibility of what one might call a “half-height space-frame” design: a partial space frame used in lieu of a ladder frame:

For some interesting short engineering essays on the optimization of tubular space-frame design for (a) a student race car, and (b) a solar powered vehicle, using computer modeling, see http://mate.tue.nl/mate/pdfs/12814.pdf and http://www.fisita.com/students/congress/sc08papers/f2008sc048.pdf

*******************************************

2. Most MAN-Neoplan Buses use Ladder-Frames and Space-Frames, and are not True Monocoque

*******************************************

Already back in 1953, MAN-Neoplan started making buses with a semi-monoque design. And in 1988, MAN introduced the “MetroLiner”:

The MetroLiner's monocoque design was 50 % lighter than more typical bus designs – see http://en.wikipedia.org/wiki/Neoplan , http://web.archive.org/web/20080602...f_NEOPLAN/History/Milestones/1982_to_1991.jsp , http://www.man.eu/man/media/en/cont.../presse_und_medien_1/BUSLIFE_1_10_Neoplan.pdf , http://www.neoplan-bus.com/cms/media/en/content/downloads/marke/jubilaeum75jahre.pdf , http://www.coachbuilt.com/bui/n/neoplan_usa/neoplan_usa.htm . Here are some images of the MetroLiner:

But apparently the MAN MetroLiner had some problems, and the design was not followed up with future model derivations – see http://www.traditionsbus.de/Fahrzeuge/neo_mic.htm , and http://translate.google.co.uk/trans...://www.traditionsbus.de/Fahrzeuge/neo_mic.htm . If you type “MAN + Neoplan + Monocoque” into google, you will get pretty much nothing, except for references to this 1988 Metroliner.

*******************************************

CONTINUED IN NEXT POST

.

CONTINUED FROM PREVIOUS POST

*******************************************

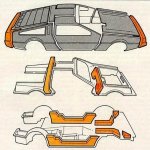

There is also clearly the possibility of what one might call a “half-height space-frame” design: a partial space frame used in lieu of a ladder frame:

For some interesting short engineering essays on the optimization of tubular space-frame design for (a) a student race car, and (b) a solar powered vehicle, using computer modeling, see http://mate.tue.nl/mate/pdfs/12814.pdf and http://www.fisita.com/students/congress/sc08papers/f2008sc048.pdf

*******************************************

2. Most MAN-Neoplan Buses use Ladder-Frames and Space-Frames, and are not True Monocoque

*******************************************

Already back in 1953, MAN-Neoplan started making buses with a semi-monoque design. And in 1988, MAN introduced the “MetroLiner”:

The first full monocoque bus in the world which no longer needed any supporting chassis or skeleton. This carbon design vehicle was made as a complete cell entirely of plastic. The exterior of the new NEOPLAN, which was given the name Metroliner, was just as futuristic as the concept as a whole. The Metroliner's low weight made it ideal for alternative drive systems such as hybrid or fuel cell concepts.

The MetroLiner's monocoque design was 50 % lighter than more typical bus designs – see http://en.wikipedia.org/wiki/Neoplan , http://web.archive.org/web/20080602...f_NEOPLAN/History/Milestones/1982_to_1991.jsp , http://www.man.eu/man/media/en/cont.../presse_und_medien_1/BUSLIFE_1_10_Neoplan.pdf , http://www.neoplan-bus.com/cms/media/en/content/downloads/marke/jubilaeum75jahre.pdf , http://www.coachbuilt.com/bui/n/neoplan_usa/neoplan_usa.htm . Here are some images of the MetroLiner:

But apparently the MAN MetroLiner had some problems, and the design was not followed up with future model derivations – see http://www.traditionsbus.de/Fahrzeuge/neo_mic.htm , and http://translate.google.co.uk/trans...://www.traditionsbus.de/Fahrzeuge/neo_mic.htm . If you type “MAN + Neoplan + Monocoque” into google, you will get pretty much nothing, except for references to this 1988 Metroliner.

*******************************************

CONTINUED IN NEXT POST

.

Last edited: