Questions

Couple items I'm pondering and would love to have input on from the collective:

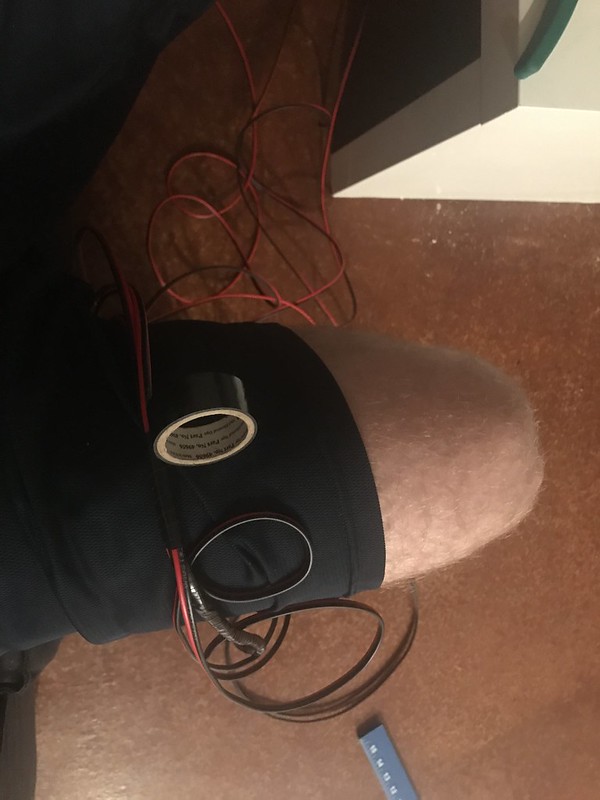

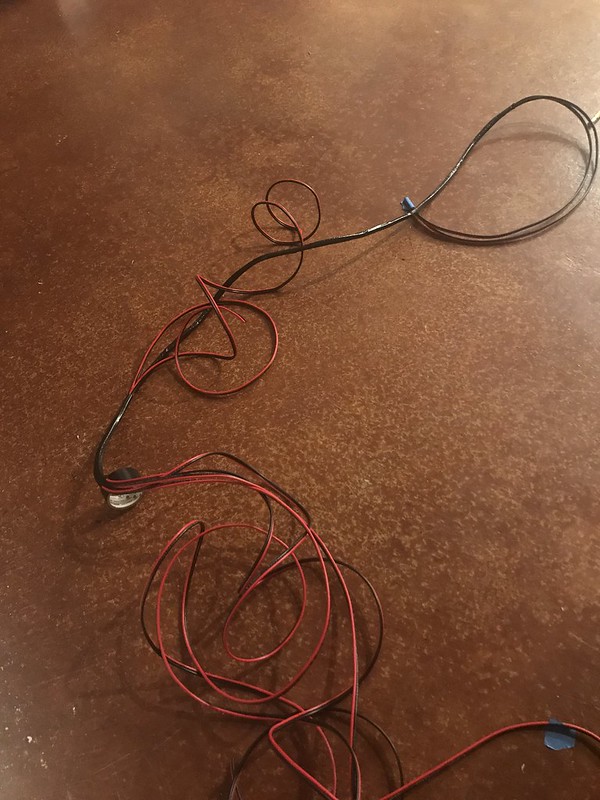

With the battery bank outside the van (in the spare tire location) I need someway of getting the power inside. I orginally contemplated running all of the cables all the way out to the battery bank through weatherproof bulkhead fittings. However we're talking a lot of holes in the floor (Inverter +/-, Solar +/-, Fuse Panel +/-, Battery Voltage Sensor, Battery Temp Sensor at a minimum (plus the water lines, propane etc. I'm thinking a remote mounted set of power posts (

Link) is a better solution. My qustion/concern is whether the inverter circuit needs to be entirely isolated. Could I run a single set of 2 AWG +/- cables to the remote posts under the van then hook up inverter, solar, and main power to the posts inside? Or should I do a separate run of 2 AWG directly from the battery to inverter? How isolated does the inverter ciruit need to be?

Also trying to fin creative uses of space is the name of the game. I'm looking for a good place to mount my solar charge controller. The sink/stove cabinet will have a 7" fixed panel covering the recess for the sink/stove unit. It would be an ideal spot for the controller, power grommet and some switches to mount unobtrusively and conveniently. However I'm a bit concerned about combining electric, propane, and water in the same compartment. Thoughts? I don't anticipate leaks but want to be safe. Would a plywood divider separating the eletcric from the sink/stove be enough? The shelf below will not be full length so water pooling wouldn't be an issue (there won't be a bottom below the sink). Is this a workable solution or should I right it off entirely and find a different spot?

Also any reccomenations on insulation materials for the inside of the various channels and doors. I'm hesistant to spray foam and permenantly seal in wiring and prevent future access. Not a big fan of fiberglass, though it's cheap, easy, and readily available due to compaction, water absorption and dust. I would love to find some recycled plastic bottle insulation, it seems very popular and radily available in the UK but I can't find a USA supplier. I've also considered hemp and wool, but moisture absorption and long term durability ar concerns. I've looked at ceramic batts and that may be an option, I don't need a lot so while pricey it may be a good choice. Just wondering if someone has found a great option I haven't considered yet (or knows a USA source for the recycled PET).

Also I remeber seeing an Express build on here a while back where someone used a marine deck fill behind the rear barn door for their water inlet but didn;t bookmark and cannot find the thread. IIRC they originally mounted the fill in the rear bumper. If anyone happens to recall the thread that would be wonderful. The common 3" flange deckfills seem slightly too large based on my measurements.