IdaSHO

IDACAMPER

Still waiting on the cylinder head to be finished by the machine shop, so I dug into the transfercase gear swap.

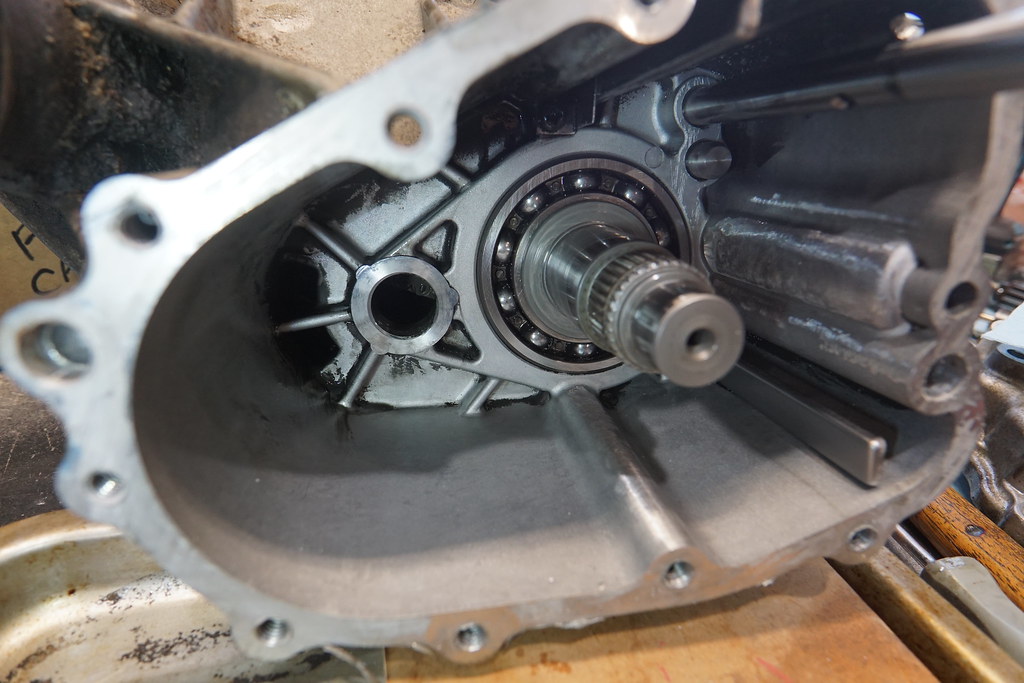

Trans was removed from the chassis and transfercase separated and plopped on the bench.

Its a cute little thing

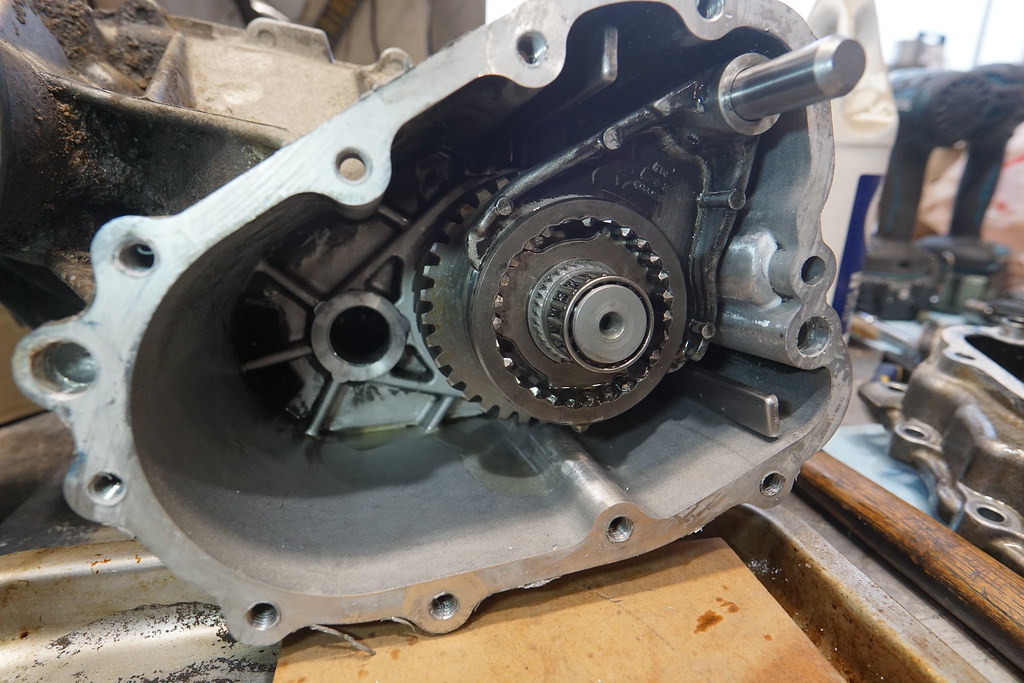

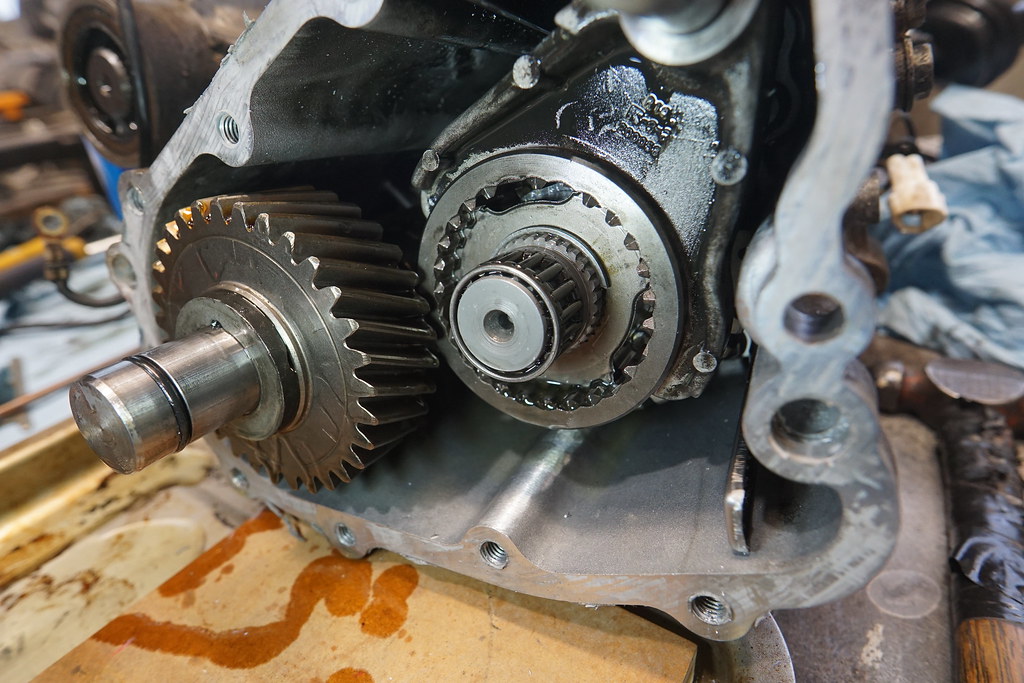

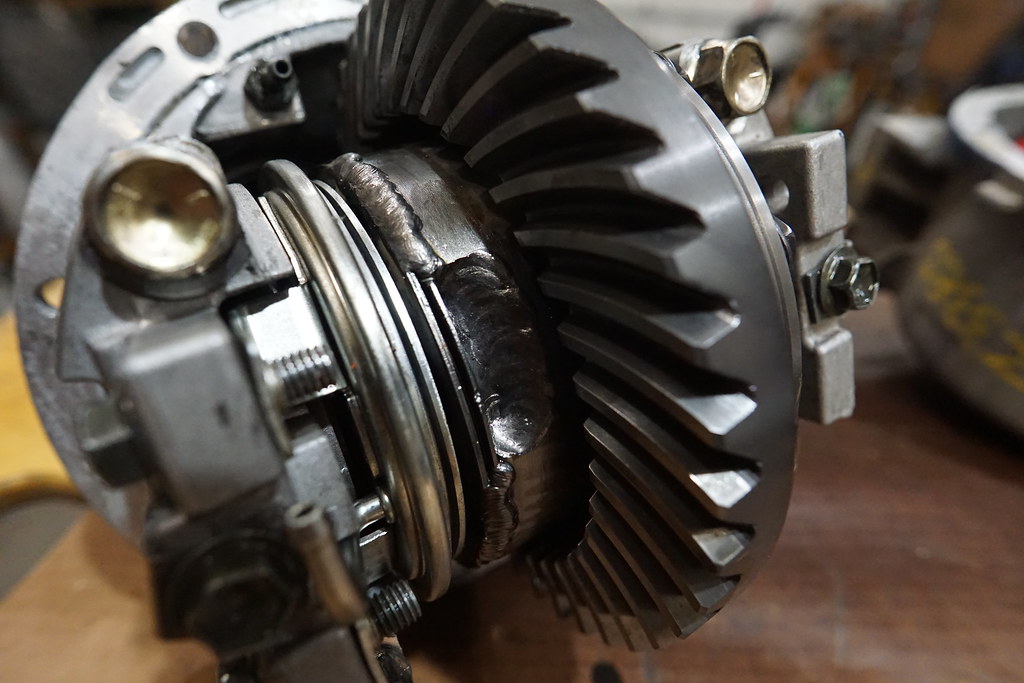

The gears are legit Japanese gears, that provide a 72% low range reduction over stock.

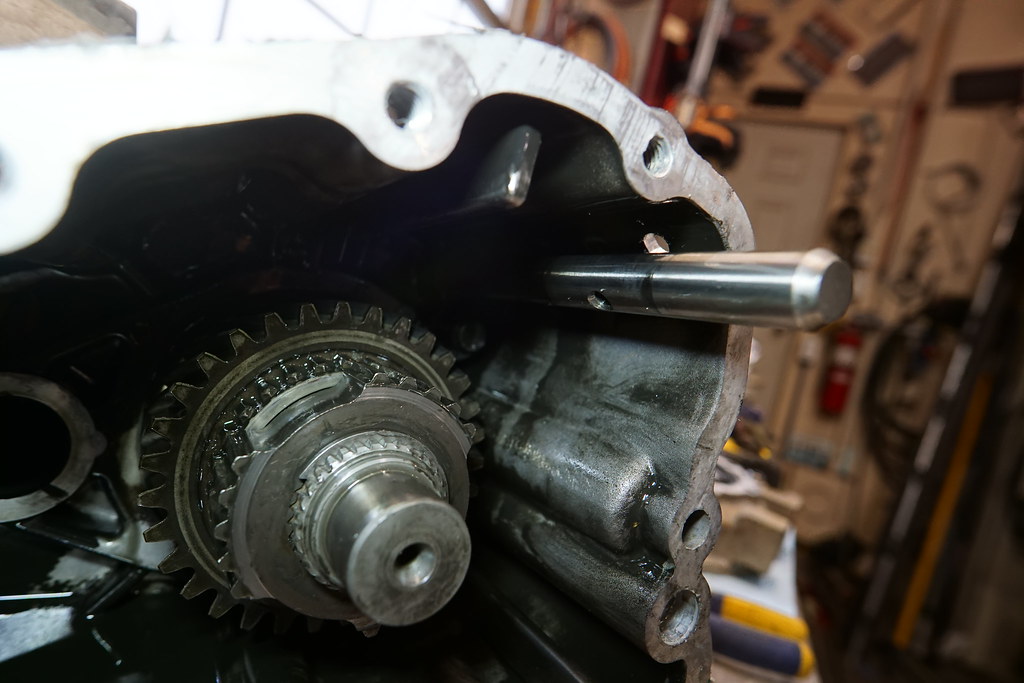

A bit of clearancing is the case is required to fit the new gears.

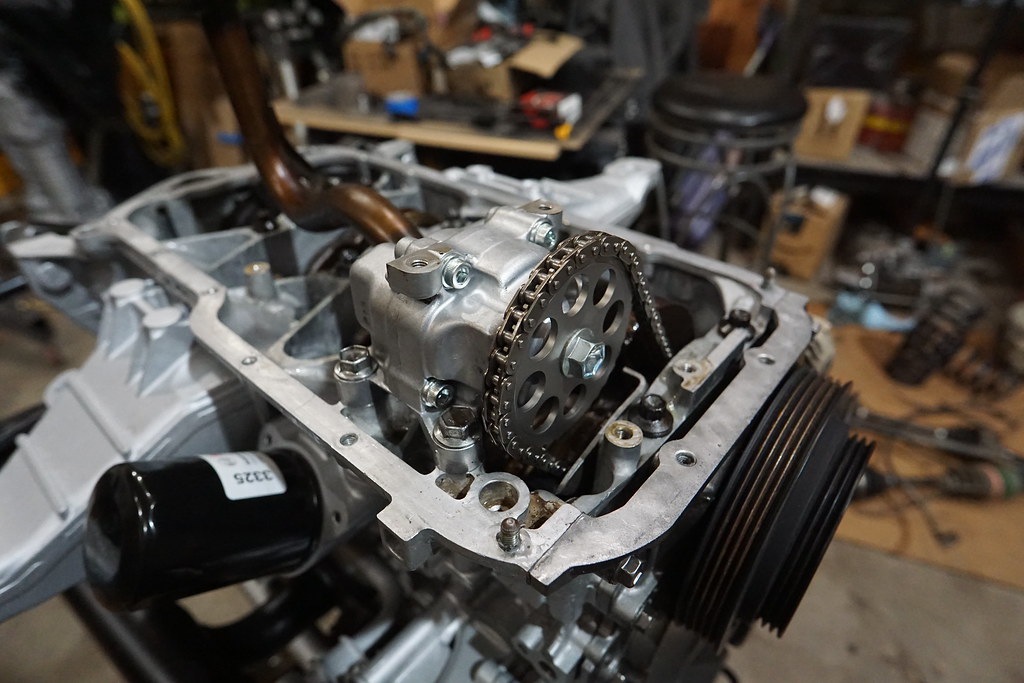

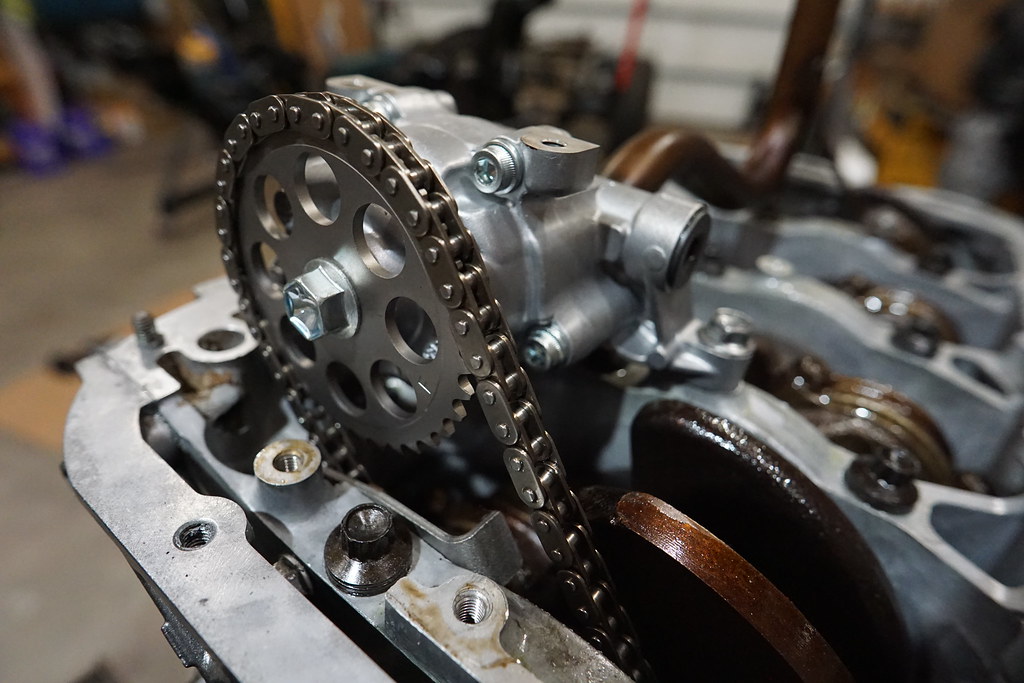

By design and according to the instruction you must disassemble the shifter mechanism and rods,

but I ran across a "shortcut" that involved drilling a small hole in the top of the case to access the shift fork roll pin.

This eliminated the need to tear into the shifter mechanism, and worked out great.

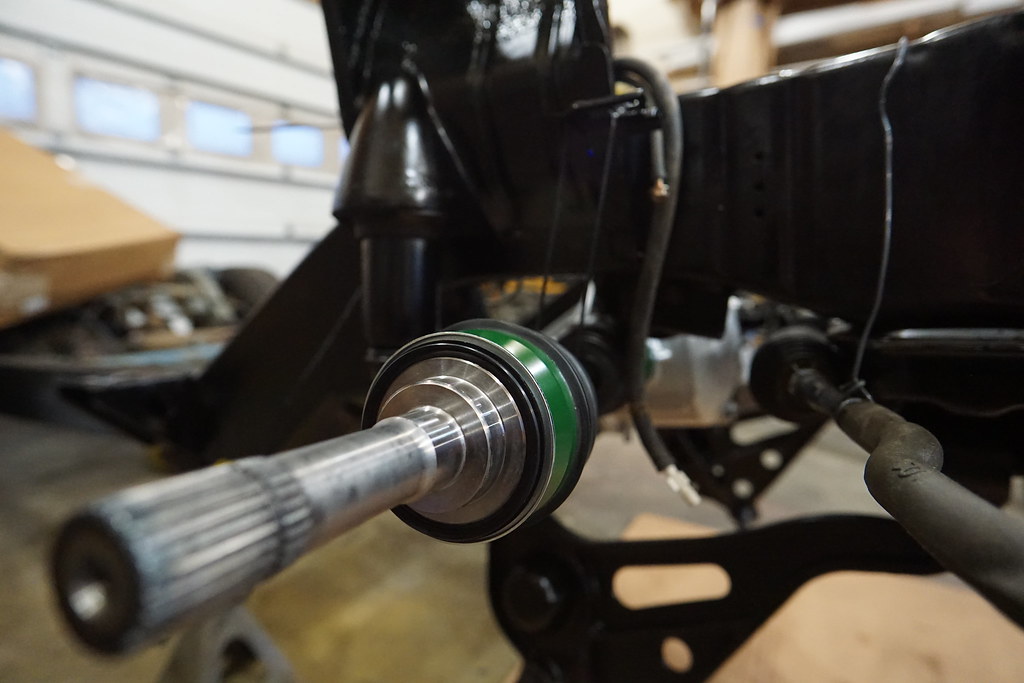

Then fresh seals on the input and outputs, and good to go.

A few photos...

Trans was removed from the chassis and transfercase separated and plopped on the bench.

Its a cute little thing

The gears are legit Japanese gears, that provide a 72% low range reduction over stock.

A bit of clearancing is the case is required to fit the new gears.

By design and according to the instruction you must disassemble the shifter mechanism and rods,

but I ran across a "shortcut" that involved drilling a small hole in the top of the case to access the shift fork roll pin.

This eliminated the need to tear into the shifter mechanism, and worked out great.

Then fresh seals on the input and outputs, and good to go.

A few photos...