Annnnnnnnd we're back.... Working on a van for 4-5 months straight and not maintaining your business can be detrimental to your pocket book, so I had to play a little catch-up! I had withdrawals from not working on the Lunchbox though, so I had to get back at it.

Working on a van for 4-5 months straight and not maintaining your business can be detrimental to your pocket book, so I had to play a little catch-up! I had withdrawals from not working on the Lunchbox though, so I had to get back at it.

I'm ready to bring the van to the house, I need it sitting here staring me in the face every day or that "out of sight out of mind" mentality really starts to set-in. So I went out to the shop to tidy a few things up on it, so we can tow it back to the house.

I don't have a welder at home, so I wanted to make sure all my major fab work was done. I can plumb brake lines, and measure drivelines here at the house, then it's driveable and I can go back out the shop if need-be. It's only going to cost $150 to have both driveshafts shortened and re-balanced, so I'm not even going to attempt that one....

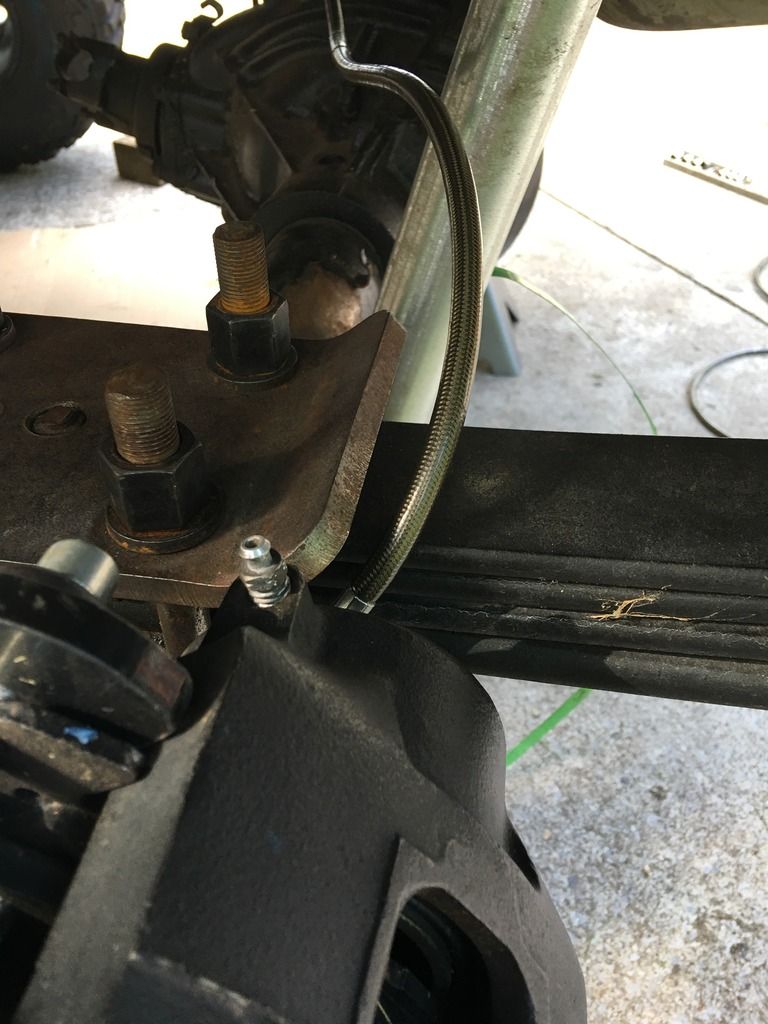

I ordered up some shorter u-bolts to remedy my problems out back. I was able to clock the caliper brackets back up where they were supposed to be, and I can get the caliper bolts in and out now that my u-bolts aren't a mile long. So that's a relief, I thought I was going to have to make new caliper brackets...

Everything else was in pretty good shape, I had completed more than I remember. I wanted to raise up my tranny crossmember a few inches, but I don't think I'm going to mess with it right now. I will have to cut out braces under the floor to move the tranny/t-case up any more, so I'm just going to build a skid plate for it and hopefully it won't drag too bad. I will mess with it at a later date if I find that it's causing me problems on the trail....

This picture was taken level with the bottom of the rocker panel. I think the transfer case hangs down too low, especially for going up a ledge or something, but other people say I'm overthinking it.... IDK. I mean it is a bohemoth van, so it's not like I'm going to be able to put this thing where a jeep would go, we'll see....

The one thing I hate when I see other 4x4 vans, is how the tires aren't centered in the wheel-well, they are always sooo close to the bottom corners. I won't tolerate any rubbing under full-flex, and I wanted to make room to upgrade to 37's later (which I now regret not buying in the first place). Once the bottom of the front of the fender is trimmed, it will look right. The wheel is also turned slightly to the right...

Then I filled up the diffs with 80w90 and we hooked the wrecker to her and pulled her to the house!

She's home! My son can't wait to ride in it. Every time we leave the house it's... "Can we take the van daddy??" soon kid.... soon....

I'm ready to bring the van to the house, I need it sitting here staring me in the face every day or that "out of sight out of mind" mentality really starts to set-in. So I went out to the shop to tidy a few things up on it, so we can tow it back to the house.

I don't have a welder at home, so I wanted to make sure all my major fab work was done. I can plumb brake lines, and measure drivelines here at the house, then it's driveable and I can go back out the shop if need-be. It's only going to cost $150 to have both driveshafts shortened and re-balanced, so I'm not even going to attempt that one....

I ordered up some shorter u-bolts to remedy my problems out back. I was able to clock the caliper brackets back up where they were supposed to be, and I can get the caliper bolts in and out now that my u-bolts aren't a mile long. So that's a relief, I thought I was going to have to make new caliper brackets...

Everything else was in pretty good shape, I had completed more than I remember. I wanted to raise up my tranny crossmember a few inches, but I don't think I'm going to mess with it right now. I will have to cut out braces under the floor to move the tranny/t-case up any more, so I'm just going to build a skid plate for it and hopefully it won't drag too bad. I will mess with it at a later date if I find that it's causing me problems on the trail....

This picture was taken level with the bottom of the rocker panel. I think the transfer case hangs down too low, especially for going up a ledge or something, but other people say I'm overthinking it.... IDK. I mean it is a bohemoth van, so it's not like I'm going to be able to put this thing where a jeep would go, we'll see....

The one thing I hate when I see other 4x4 vans, is how the tires aren't centered in the wheel-well, they are always sooo close to the bottom corners. I won't tolerate any rubbing under full-flex, and I wanted to make room to upgrade to 37's later (which I now regret not buying in the first place). Once the bottom of the front of the fender is trimmed, it will look right. The wheel is also turned slightly to the right...

Then I filled up the diffs with 80w90 and we hooked the wrecker to her and pulled her to the house!

She's home! My son can't wait to ride in it. Every time we leave the house it's... "Can we take the van daddy??" soon kid.... soon....

Last edited: