Air system all roughly back together, I need to shorten a few more hoses and lengthen a couple more but it appears to be functioning just like before. Good thing I labelled everything, plus this has forced me to understand all the valves and how the system works which will come in handy in the future.

I had to make a new main compressor line, make sure the dryer cartridge could be removed after the build is done, and that the driveshaft or possible exhaust routing doesn't cause me issues. I think I got it just about there!

The crossmember I designed dropped in a treat and I used a mag-drill for match drilling all ll the frame holes. I also made a new pump mount for the hydraulic pump which came out nicely too. Got to love knowing someone who works with a laser and metal forming shop!

Now I need to find me a pair of frightliner/sterling 50 gallon fuel tanks, the most suitable north American tanks I could find except I can't seem to find any locally. I've added a couple of cheap steel underbody boxes for batteries, cab tilt hydraulics, tire pressure pneumatic system and diesel tank switch over and filter system. Will be cosy in there but it'll work nicely. I copied the cab tilt pump clearances to the cab and wheel and I'll add a mudguard to the front face of the box.

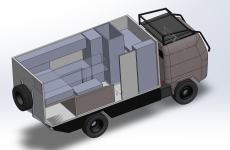

The layout and CAD model are slowly developing, choosing the best layout is proving pretty tricky since there aren't that many sleeping 4 people bed setups. The original plan of a lowering bed has been scrapped because I think the main bed will be a bit more like a couch area in the daytime, so thinking about an L shaped dinette opposite the kitchen, small bathroom which partially encloses the kids beds up front, with a crawl through sneaking between them.

Waiting on my extended driveshaft, for the rear axle, and my shortened one for the PTO. Fuel tanks, wiring, hydraulic lines and then onto subframe. Really need to hurry up and decide on a layout and habitation box supplier so I can make sure the subframe will work with the box. For anyone curious it is currently planned to be 5.5m long, 2.4m wide, outside dimensions.

Plenty to do on and in the cab while I wait for the box to be made later though, PLENTY to do....