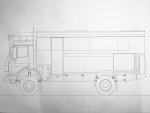

Soooo, I totally get where you are at.... You are looking at this great truck, you can picture it done, so you want it painted as it 'get's it closer to finished'... Here's the hard bit... You can't do anything until you have a plan, and by plan I mean a scale plan. I started with my truck (a Merc 1222A as that is what I know and wanted). I then drew basic body designs, looked at a few options etc etc. I finally bought an ex mine coach body that has 'the look' I wanted, and was the right length at 6m. With rough ideas in my head and a layout sketched I started work on the body. It soon became apparent that trying to keep all this stuff in my head and on scraps of paper just wasn't going to work, so I downed tools and drew two accurate drawings at 1:10 scale, and put together a sectioned folder with internal rooms, external, costings etc. Straight away I knew that was what was needed. I now have a scale plan for the layout (needed for step position, toilet, plumbing, wiring, lockers, doors, bed size etc etc etc... The list is long). I also now have a scale side view of my truck. I have something accurate to follow. It is stuck to the side of the body I'm converting, and everything I do relates back to this drawing. With accurate plans, you can then factor in house battery locations, water filtration and storage, switchboard and charger locations, etc etc. In my view, (and I'm by no means an expert), by having a plan, I have hopefully foreseen most things, and now have things where I want them and where they need to be. Little things like the cab access to body doors... They were in the center (as that seemed logical).. and they were going to be sliding as that also seemed logical... Now I have a scale plan and can see it, they changed. The opening is offset to the right nearer to the driver (because if the crawl thru is being used whilst mobile, it's not being used by the driver!) The passenger has better access. Now instead of 2 sliding doors, I am having one sliding door (cab side that slides behind passenger seat), and one hinged smaller door (body side), which opens into the cab (thru sliding door opening and against drivers seat). This makes it secure and a proper draft free door. Little things keep evolving as I go, but the bulk of the plan is staying the same. Get the tape measure out and then put pen to paper before doing anything. With that you can then play truck!