Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unimogadventures - Our build and travel thread

- Thread starter Iain_U1250

- Start date

Iain_U1250

Explorer

Another video, we just keep on making them

Sitec

Adventurer

The camper box also got it's insulation - first the layers of bubble wrap foil,

View attachment 83450

then the polyester wool bats.

View attachment 83449

Hi Ian. So I'm almost at the point of interior cladding. We have started insulating using 50mm Kingspan fitted in the sections between the frame and bonded to the outer aluminium skin. I've tracked back through your thread to here, to see what you did. It looks fairly similar.

My question... I see you have then attached ith interior lining ply to the steel frame inside. Have you had any issues with condensation along the steel lines? I was planning to overlay the inside of our Hab Box with a further 10mm of roof insulation (silver foil either side) to give us 60mm total insulation and 10mm over the steel frame, in the hopes to stop the thermal bridge, condensation and possibly mould... but seeing this I now wonder if it's necessary...? Sketch attached of what I'm planning... I'd be interested to know how your Hab Box interior goes on a cold night... Cheers.

Attachments

Iain_U1250

Explorer

Hi Simon, my internal lining is made from a composite of marine ply, laminex and, 5mm of aerogel insulation, http://www.aerogel.com.au/products-and-services/spaceloft which is one of the best insulation materials you can get. We have no thermal bridging whatsoever. I tried measuring the temperature of the wall with the heat gun, and could not see any difference where the steel supports are.

I have the foil bubble wrap on the aluminim skin, and the Higgins Insulation batts on the rest. Do a test on the Kingspan - see if it burns and if it stay alight, then take a wiff of the smoke - you will soon tell if it is bad for you. The Higgins was self extinguishing and non toxic.

Regarding the tubing, each on of my tubes has a 5mm hole drilled into the bottom to let any condensation moisture out. If you don't, then eventually moisture will build up in the tubes, may take years but without some way of letting the moisture out, it does build up. I also drilled an 8mm hole at the top, and I sprayed cavity wax into the top of each tube - using one of those long flexible nozzles until the wax came out the bottom, I used a total of 5 litres in all. (Took a long time to stop dripping but it did after a few months over summer) Might be overkill ( like everything else) but I wanted mine to last forever

Under the windows, I put a layer of the truck side sail material, so that any leaks inside the window flow down to the bottom, where there is a small hole or opening to let the water out into the truck - I don't want to find out the whole wall cavity has filled up with water, so far I've had no leaks, but occasional we leave the window open in the rain and get a few drips down into the window opening so it was worth the extra effort I think. A few days in 40+C will dry out the walls anyway

I have the foil bubble wrap on the aluminim skin, and the Higgins Insulation batts on the rest. Do a test on the Kingspan - see if it burns and if it stay alight, then take a wiff of the smoke - you will soon tell if it is bad for you. The Higgins was self extinguishing and non toxic.

Regarding the tubing, each on of my tubes has a 5mm hole drilled into the bottom to let any condensation moisture out. If you don't, then eventually moisture will build up in the tubes, may take years but without some way of letting the moisture out, it does build up. I also drilled an 8mm hole at the top, and I sprayed cavity wax into the top of each tube - using one of those long flexible nozzles until the wax came out the bottom, I used a total of 5 litres in all. (Took a long time to stop dripping but it did after a few months over summer) Might be overkill ( like everything else) but I wanted mine to last forever

Under the windows, I put a layer of the truck side sail material, so that any leaks inside the window flow down to the bottom, where there is a small hole or opening to let the water out into the truck - I don't want to find out the whole wall cavity has filled up with water, so far I've had no leaks, but occasional we leave the window open in the rain and get a few drips down into the window opening so it was worth the extra effort I think. A few days in 40+C will dry out the walls anyway

Iain_U1250

Explorer

Iain_U1250

Explorer

Now I need to work out how the pneumatic shifting works - does it need constant pressure or just when shifting, the Reverse cylinder seems like it does have a spring return, but not sure. The High/Low ( Working gears) is a standard shift cylinder like on the 1-4/5-8 range change. Pretty sure that has constant air supply, but will do some tests.

Iain_U1250

Explorer

Still waiting for the missing parts to do the transmission swap, but I have made the switch console, and have the parts for the valve block. I'll get the switch engrave with F R and H L and the other is will be 4WD.

The console is made from 1.8mm Balsa wood, with some fibreglass resin and a layer of matting, the top where the switches are is 5mm balsa. I did this so that if we ever have an accident, the console would crush, and not chop my knees off like and aluminium one would. I had about 3-4" of clearance to my knees when sitting on the seat with it as far forward as possible, amore when it's i the normal position.

The switch will control the pneumatic valves for forward/ reverse and high/ low range. I'll have an interlock so that my foot has to be on the clutch and hard on the brakes to change gear.

I'll proably mount the valve block behind the passenger seat, as they are only rated to -10C, but if there is not enough space, I'll have to find another place. I'm hoping the missing parts arrive in the next week or so, and then it will be time to drop out the old transmission and Claas overdrive, and install the new one. Everything seems to fit, the flanges on the driveshafts are the same, but the new transmission is a bit taller, and I have an underfloor box over the top of the transmission, worst case scenario is that I have to cut and shorten the box a bit, but I'll see in a week or two.

The console is made from 1.8mm Balsa wood, with some fibreglass resin and a layer of matting, the top where the switches are is 5mm balsa. I did this so that if we ever have an accident, the console would crush, and not chop my knees off like and aluminium one would. I had about 3-4" of clearance to my knees when sitting on the seat with it as far forward as possible, amore when it's i the normal position.

The switch will control the pneumatic valves for forward/ reverse and high/ low range. I'll have an interlock so that my foot has to be on the clutch and hard on the brakes to change gear.

I'll proably mount the valve block behind the passenger seat, as they are only rated to -10C, but if there is not enough space, I'll have to find another place. I'm hoping the missing parts arrive in the next week or so, and then it will be time to drop out the old transmission and Claas overdrive, and install the new one. Everything seems to fit, the flanges on the driveshafts are the same, but the new transmission is a bit taller, and I have an underfloor box over the top of the transmission, worst case scenario is that I have to cut and shorten the box a bit, but I'll see in a week or two.

Jostt

Adventurer

Hello Ian, this gear box you bought has longer ratios than the std one you have now? And I see it has working gears, I'm looking to upgrade also my unit with one with working gears, because the one I have doesn't have the right output shaft to add it, so I'm collecting info about this, it's one area I was not thinking on it until now, if I remember well there is two different types, the low and super low, is it right? MOG central is in USA, right? Thanks in advance Ian

Iain_U1250

Explorer

HI, Mog Central is in Australia. The gearbox has a 0.736 8th gear ratio, so no need for the Claas overdrive. I have the working gears. There are even lower crawler gear sets, but that is just for doing things like planting crops or something. This video show the difference between the three gear sets.

charlieaarons

Explorer

The G21 option is for working gears = 5.76:1. It comes on UGNs and later versions of “implement carrier. It’s a bit too slow for sand, for instance.

G22 is what comes with more recent versions of UHN, which look more like Iain’s and are for more offroad work. Low range is only 3.19:1, paradoxically better for sand.

You have to have either one with the overdriven gearbox, 1st road gear is 9.57;1; too tall, without additional working gears.

I imagine that you can order either one when buying a rebuilt unit.

There’s only 2 possible practical reasons for additional crawling gears (additional 9.75 multiplication). 1) matching wheel speed to hydraulic winch speed. 2) ultra slow crawling one wheel, with diffs locked, onto a rock to level camper so that you sleep more comfortably (I have actually done this).

G22 is what comes with more recent versions of UHN, which look more like Iain’s and are for more offroad work. Low range is only 3.19:1, paradoxically better for sand.

You have to have either one with the overdriven gearbox, 1st road gear is 9.57;1; too tall, without additional working gears.

I imagine that you can order either one when buying a rebuilt unit.

There’s only 2 possible practical reasons for additional crawling gears (additional 9.75 multiplication). 1) matching wheel speed to hydraulic winch speed. 2) ultra slow crawling one wheel, with diffs locked, onto a rock to level camper so that you sleep more comfortably (I have actually done this).

Iain_U1250

Explorer

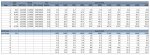

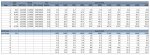

The great gearbox swap has started. Here is my gear ratio calculations.

I've got the truck on stands, and removed the left hand fuel tank, and the tool box, so now I have full access to the transmission.

Unfortunately, I have to have a bit of surgery on my hand, so will be out of action for a few weeks, at least that's what the the surgeon thinks

I've got the truck on stands, and removed the left hand fuel tank, and the tool box, so now I have full access to the transmission.

Unfortunately, I have to have a bit of surgery on my hand, so will be out of action for a few weeks, at least that's what the the surgeon thinks

Last edited:

Jostt

Adventurer

Good luck on your surgery Ian, thanks for the info, looking at the video I think working gears would be optimal for my MOG use, crawl looks like to low, for agri mybe but not for my use, with the power of my truck I would like to keep the ratios I have now so I will try to find one gearbox like myone but with working gears, it's maybe the combo you have now in your truck, thanks again Ian

Iain_U1250

Explorer

Finally finished our Walkaround video - it;s pretty long, so grab a coffee or a beer ( or two)

I even get to talk - for all of 20 seconds.

I even get to talk - for all of 20 seconds.

Last edited:

MogsAndDogs

Active member

Excellent video. Thank you for the detail!

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 7

- Views

- 404

- Replies

- 0

- Views

- 2K

- Replies

- 7

- Views

- 3K