I have wanted to update this thread for a while. First I'll address the All-Pro Uniball A-arms.

To refresh, while my 4Runner was in for gears and lockers it was discovered that the bolts running through the All-Pro Uniballs were bent, the right side worse than the left. The bends were near the middle of the bolt, where the bolt lives inside the tapered extension of the Uniball ball-joint.

The taper on the bottom of the ball-joint was not a snug fit as it should be. The tapered end of the ball-joint would easily spin/rotate in the steering upright taper when the nut on the bottom of the ball-joint was turned. The taper on these Uniball joints is built in, not a sleeve/adapter like the pictures shown earlier of the Total Chaos fittings. I didn’t have a camera to document the All Pro taper before they were ground off, but there was clearly not enough length nor proper engagement in the steering arm.

The fix was to cut off the tapered extension on the bottom of the All-Pro Uniball, replace the bent bolts with new Grade-8 9/16” bolts, and have custom tapered sleeve adapters machined to correctly fit the inside of the 4Runner’s steering knuckle.

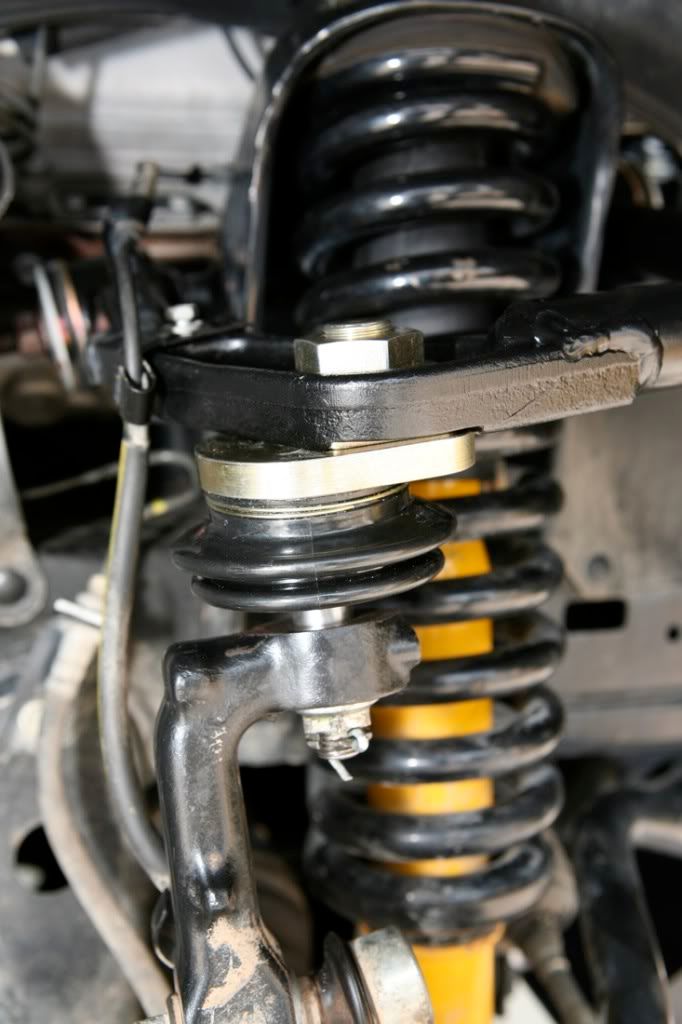

These are pics of the new, machined, tapered adapters I had made:

Tapered sleeve on the ball-joint bolt:

I was not happy that these modifications were needed. With the modified Uniballs and custom taper/sleeves installed the car drove better, and the steering looseness the car had developed was gone. This fix may have been permanent, but I had a hard time continuing to use a product that ‘was not right’ and that was not supported to my satisfaction.

Light Racing/SPC Upper A-arms w/stock type ball-joint

With the promise of the correct taper for the 4Runner’s steering knuckle (different part numbers for 4Runner/FJC & Tacomas), quiet & smooth operation with equal travel to that of a Uniball, and stock-type longevity, I decided to buy a pair of the recently released Light Racing/Specialty Products upper A-Arms.

I had a mechanic install the Light Racing arms for me, but I was there and assisted and together we decided what position to clock the ball joints for additional caster. It should be noted that Light Racing’s instructions are vague and they need both better pictures and some text to explain how they should be set-up. One of my thoughts choosing the All-Pro Uniball arms over a more adjustable A-Arm like the Icons (in addition to cost!) was that alignment would be easier for most shops to perform. I was correct. After the All-Pro Arms were installed, it was very easy for anyone with an alignment rack to align the 4Runner using the stock adjusters.

In the case of the super adjustability of the Light Racing ball joints, not only was the alignment all screwed-up after installing the A-arms, the first kid that tried to do an alignment couldn’t do it with where we had the ball joints clocked. He tried moving them to a different position but he made it worse. The next day a different guy at the same shop (manager) moved the ball joints and did an alignment that was ‘within spec’. Though within alignment specifications, it was later clear that the set-up was “not right”.

One obvious issue was that this shop thought that the small ‘SPC’ markings on the ball joints needed to face outward, “because all product names always face out”. This was even after I had called SPC and confirmed that the SPC letters would not always face outward, the lettering may face inward or to the rear depending on how the ball joints are clocked. They wouldn’t listen and adjusted them the way they thought they should be. They had a copy of the (poor) instructions but I’m not sure they did much more than look at the few pictures.

After aligning the Light Racing (LPC) arms and doing some light 4-wheeling, I started experiencing some tire rubbing at the rear of the left-front fender that I didn’t have before with the All-Pro A-arms. This may have been because I now had 3.5 - 3.7 degrees of caster, pushing the tires further to the rear than when I was running closer to 2.5 - 2.7 with the All-Pros. Maybe the front springs have relaxed (I don't think so), or I just needed to extend my front bump-stops a bit which I hadn’t done yet.

The Light Racing A-Arms were now set-up okay, and the alignment was within spec per the alignment computer, but my butt meter and some critical thinking told me something wasn't exactly right.

After the recommendation from two friends, both with Land Cruisers, I tried a new alignment shop. This shop can align large RVs (uncommon) and also does custom alignments on lowered, raised, and race vehicles. They are very good. About two weeks ago I explained the issues and they listened. Before making any changes my New Alignment Master ‘Mike’ found that the upper ball joint nut (for adjusting camber) took less than 100-lb-ft to loosen, though it should have been set at 120-lb-ft. Mike first zeroed the stock adjusters, then changed the clock of the ball joints to a better, more neutral position for the amount of lift I have, then did an alignment. This guy is good, exacting and a friendly, pleasant guy. The car drove better than ever and as good as stock. I was very happy - until my first off-highway trip where there was a problem.

To be continued...