jmnielsen

Tinkerer

Seems this is as good of an area as any to ask this question here.

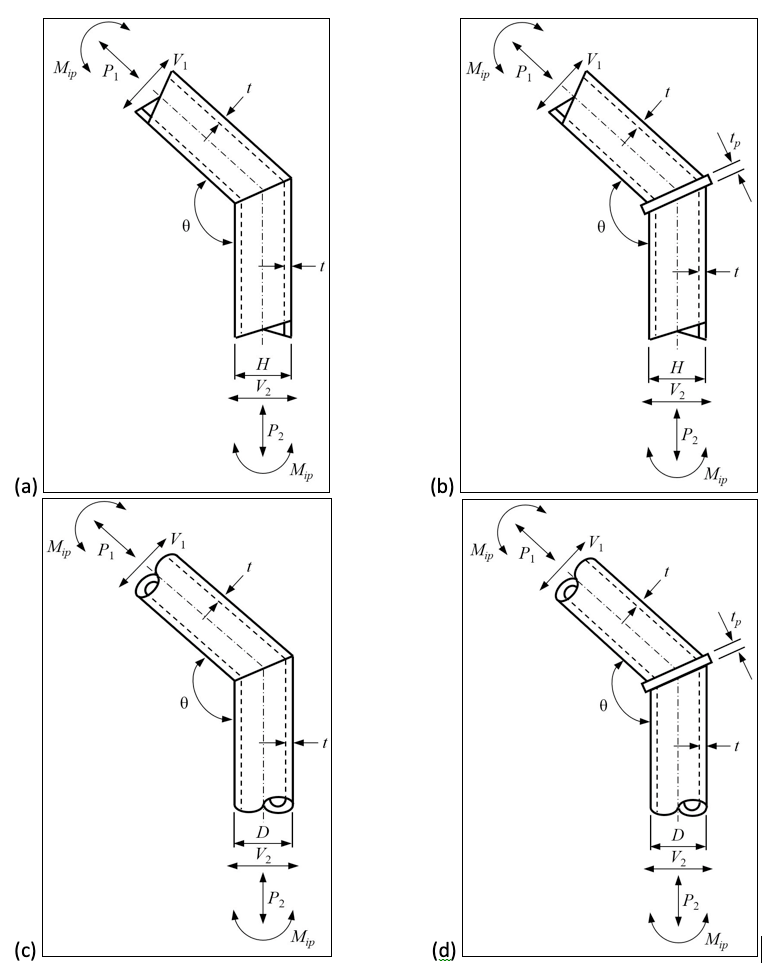

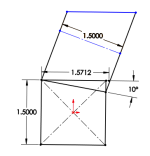

I'm in the design phase of a project and am curious the standard way of welding square tube that is cut at an angle to square tube of the same size, example below.

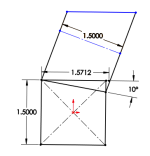

Here I have 1.5" square tube that is cut at a 10° angle that needs to be welded to the top of another piece of 1.5" square tube.

Obviously the mating length on that 10° cut is longer than 1.5" (1.5712" in this case).

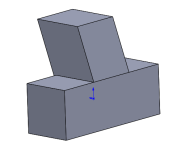

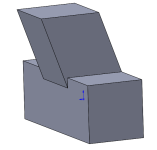

What is the proper way to mate these two pieces? Cut the angled piece so that it fits the square (making an "L") like shown in the picture?

Thanks!

I'm in the design phase of a project and am curious the standard way of welding square tube that is cut at an angle to square tube of the same size, example below.

Here I have 1.5" square tube that is cut at a 10° angle that needs to be welded to the top of another piece of 1.5" square tube.

Obviously the mating length on that 10° cut is longer than 1.5" (1.5712" in this case).

What is the proper way to mate these two pieces? Cut the angled piece so that it fits the square (making an "L") like shown in the picture?

Thanks!