Alloy

Well-known member

What do you recomend? I haven't found anything with that sort of rating. Would you mind linking something?

You'll only find 5-6:1 SWL ratings on lifting equipment but that's what I use for recovery gear.

What do you recomend? I haven't found anything with that sort of rating. Would you mind linking something?

I just want the strongest hitch pin you can get. What is it?

Weirdly my hitch, recievers or my pin didn't come with any instructions telling me how failures will happen. And when they do, I had no clue it could be assumed they will all behave the same, as yours did, under the varying conditions I am likely to put them through. And maybe even weirder I had no knowledge of your hitch destruction results until you just told me about them. I mentioned my ME qualifications up front and wouldn't have any idea about such things. Maybe I should have known these things by osmosis.I'm missing the desire for the strongest. I've made the holes in a 1/4" thick receiver tube oval using a $5 hitch pin.

That sounds one better than the Grade 8's. Thank you!I use a long M16 grade 12.9 socket head set screw with the thread section cut off.

Hobson-Stainless-Steel-High-Tensile-Fastener-Guides.pdf (aimsindustrial.com.au)

Cheers,

Peter

OKA196 motorhome

Your hitch, recievers and pins all have lifting equipment ratings? sweet. What brand?You'll only find 5-6:1 SWL ratings on lifting equipment but that's what I use for recovery gear.

Your hitch, recievers and pins all have lifting equipment ratings? sweet. What brand?

Weirdly my hitch, recievers or my pin didn't come with any instructions telling me how failures will happen. And when they do, I had no clue it could be assumed they will all behave the same, as yours did, under the varying conditions I am likely to put them through. And maybe even weirder I had no knowledge of your hitch destruction results until you just told me about them. I mentioned my ME qualifications up front and wouldn't have any idea about such things. Maybe I should have known these things by osmosis.

Personally I would rather try and verify every link in the chain in an attempt not be suprised by a weak link. It would be one thing if this were common knowledge, pinned at the top of the board....maybe you and all the others here already know the failure points of their hitches before having pushed them to that point and if so I apologize for wasting all your time by making you read my post. when I should have been asking what are these wonderful hitches you own which dfine these things.

I looked up the Factor55 hitch pin, and I don’t see where it is rated. I saw a statement that it has a shear strength of 50,000+ lbs, which is not the same thing as a rating, and when considering a safety factor is little different than the Curt hitch pin referenced earlier that states it’s strong enough to tow 21,000+ lb trailers.

Maybe someone mentioned but I missed it . . .

Isn't a huge advantage of the hitch pin method, the elimination of a large, heavy projectile?

Use a good pin, throw a blanket/damper over the strap, and keep your distance.

What we want is a strong low mass connection to a properly supported hitch pin with large safe working radii for all the components in the system.

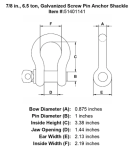

View attachment 768741View attachment 768742

I agree that insert is the way to go for hitch recovery.

I am glad to have a factory recovery point F/R, to use w/ my 7/8" D-ring shackles.