DaveInDenver

Middle Income Semi-Redneck

This is not true. A grade 8 bolt is always higher strength than a grade 5.Great points but I'll say from experience that Grade 8 is way more prone to brittle breakage than Grade 5. That's why Grade 5 is called out in many applications and specify not to use 8. As somebody who has replaced grade 8 with grade 5 bolts because of breakage and lack of clamping stretch, lack of reusability in bolt applications I can attest to that. Cost savings of grade 5 aren't that significant, so why don't we just use Grade 8 everywhere? Again depends on application and engineering call outs.

I know nothing really and you're probably right, I'm sure in this application the welds will fail before the pin. But I'll stand by my preference for bending rather than breaking in winching.

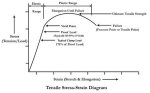

While you are right that heat treating to achieve grade 8 does cause the plastic region of the bolt to decrease. That only means that the transition region from recoverable bending (elastic, meaning it returns to it's original shape) to permanent deformation (elongation) to ultimate is smaller.

However the flip side is the point where a grade 8 starts to elongate is higher than the yield (break) point of a grade 5.

Putting numbers to it. Say you have a 5/8" bolt and for the sake of argument you only look at the unthreaded shank so that it's actually 5/8" diameter.

The sectional area is:

The specs for bolts are generally by ASTM A354 or SAE J429.

5/8" SAE Grade 5:

Proof of 85 ksi * 0.31 sq-in = 26,350 lbf

Yield of 92 ksi * 0.31 = 28,520 lbf

Ultimate of 120 ksi * 0.31 = 37,200 lbf

5/8" SAE Grade 8:

Proof of 120 ksi * 0.31 sq-in = 37,200 lbf

Yield of 130 ksi * 0.31 = 40,300 lbf

Ultimate of 150 ksi * 0.31 = 46,500 lbf

BTW, as it happens a Grade 8 5/8" bolt has very nearly the same ultimate strength as a standard 4.75 ton bow shackle. That rigging is dictated by the ASME B30.26 standard to have a minimum of 5:1 design margin.

So a WLL shackle at 4.75 ton WLL will break no lower than 5 x 4.75 tons = 23.75 t = 47,500 lbf.

Although sticking to the proper WLL of 9,500 lbf on this shackle is exceeded by either Grade 5 or Grade 8 so there's no concern to using either as a hitch pin. Proof load per ASME B30.26 is 2:1, so a 4.75t shackle will handle 19,000 lbf without damage and even this is still lower than proof on both bolt types.

The reason various SAE grades exist is mainly cost. If you don't need Grade 8 and it costs a nickel more to the OEM per bolt they'll use the lowest spec that meets the need and put the difference to profit using millions of them.

Last edited: