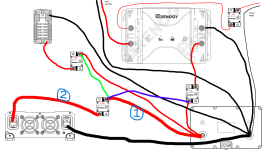

This is my wiring plan for a van conversion. Renogy 50A charger, battery and 1000Winverter. I'm using circuit breakers on all the main circuits and then a fuse box for the individual house loads.

Ignoring the blue and green lines for a second, everything is straightforward and simple. I have a 35mm2 wire from the battery to the inverter, rated to 240A and a 150A breaker for the inverter.

Cable runs are short, less than a metre total.

Which got me to thinking. Do I need to run a feed direct from the battery positive to the 50A breaker feeding the fuse box or could I put in the green wire and go from the 150A breaker input terminal. I can't really see why not?

The flip side then is the blue wire from the charger to the same terminal. I'm thinking that's a bad idea because we want the charger seeing the battery voltage at the battery terminals? or does it matter? I know the total load could be 260A there which exceeds the cable anyway so not applicable but curious for future knowledge sake.