For comparison, here is a more traditionally built plank on frame boat - but with epoxy as well. Fasteners are used, but I'm unsure of where and howm many. This boat was built by a fellow to be hs charter boat in the Oregon Inlet area of the Outer Banks of NC, in Dare Co., where many wood boats are built. The last one, the 65'er was built there as well, Wanchese in in Dare Co.

Imagine building an off road tear drop with this method or cold molded.... Strong, lightweight,....

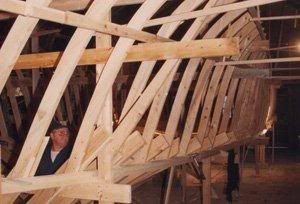

Here is the builder shaping a frame.

The beginning.

Progress on the frames.

More progress on the frames.

Juniper planking, juniper because of its light weight, dimensional stability and its impervious to water characteristics. The juniper planks are edge glued and I believe mechanically fastened to the frames. If mechanically fastened, probably with bronze screws to prevent corrosive expansion of the fastener in the case of contact with sea water.

Often plywood is epoxied over the base planking for additional strength and to ease fairing and finishing. No photo of this though, and this boat may not have had plywood applied, though it probably did.

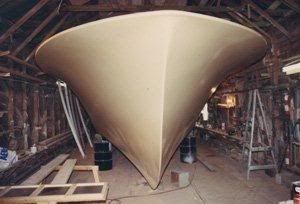

Finished hull, glassed over and at least partially faired. The interior would be at least "pickled" with epoxy, meaning well sealed with epoxy thin enough to soak into the wood some. Those plank on frame boats I been below decks on were also painted. Some had glass mat in the engine room or other places where wear and abrasion could be expected.

Finished hull shot, faired and painted.

The boat running, its called Marlin Fever.

In plank on frame boats the frames stay in the finished boat, adding weight and also taking up some interior cubes. Still, the end result is a very strong boat up to running off shore daily for decades.

Either the more traditional technique, with modern materials - glass, epoxy, structural epoxy putty fillets, etc. or cold molded.... Great choices. Or the "Stitch and Glue" method shown by Heifer Boy would make a great trailer...

From what I have seen, tear drop builders build more along the lines of plank and frame, especially the roof. If they are not using boat building techniques they ought to. Stronger, lighter, waterproof quiet...

JPK