barlowrs

Explorer

Well I finally pulled off my all-pro bumper for some “alterations” I have been planning, on while it was off, I took the time to do a few fixes on the winch.

First off, grease. For anyone that has tried to freewheel the XRC out, you will know you have to pull DAMN hard. The grease they use inside this thing is more like glue than grease. So I decided to open her up and put some GOOD grease in it.

Here you can see the gooey grease they use:

After a LOT of degreasing, I finally got the gears cleaned off and started to rebuild it.

Here you can see it packed with some good quality grease!

Once I got her back together, the difference was night and day, you could pull the line out with one hand and it didn’t take much force at all! It was great! I highly recommend this to ANYONE with an XRC winch.

Next up was the electrical stuff. Something that was pointed out to me by FlatBlak (http://www.expeditionportal.com/forum/showpost.php?p=595031&postcount=22) was the electrical ground terminal. This winch pulls a LOT of current (as all winches do) so you want to make sure all terminals have a good connection, however the factory ground terminal has the majority of its surface painted:

After some scraping and filing, I had a nice surface to contact with the lugs. I feel much better about this now:

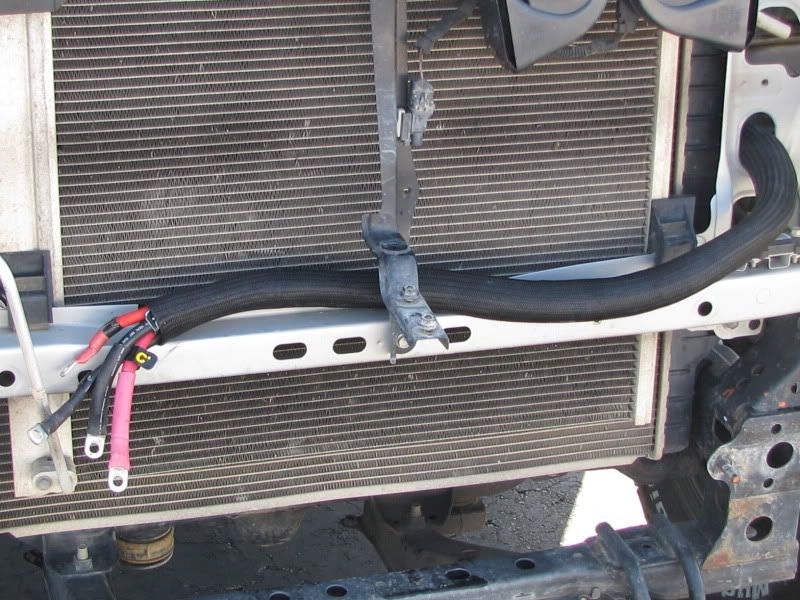

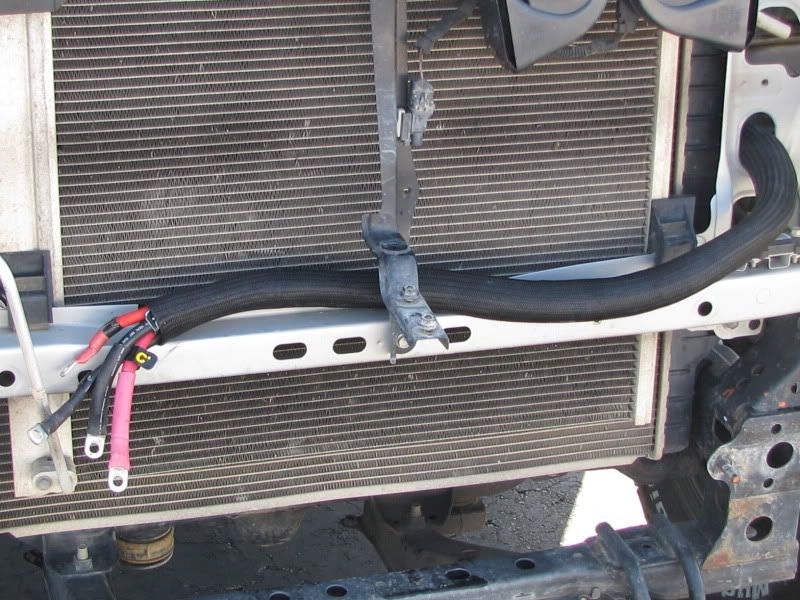

Then I decided I wanted to protect the wires a bit better up front, while I used all marine grade cables, I decided to shield them just for good measure. I shielded all the cables and put a plastic grommet where they run through the front radiator support.

One last thing I noticed when taking it apart was that there was some SLIGHT surface rust on the bolt that holds the synthetic line to the drum. I am not sure if this is a big deal, but I decided to upgrade it to stainless just in case.

I feel much better about this winch now and feel it is ready to save my @$$ if I get into some trouble.

First off, grease. For anyone that has tried to freewheel the XRC out, you will know you have to pull DAMN hard. The grease they use inside this thing is more like glue than grease. So I decided to open her up and put some GOOD grease in it.

Here you can see the gooey grease they use:

After a LOT of degreasing, I finally got the gears cleaned off and started to rebuild it.

Here you can see it packed with some good quality grease!

Once I got her back together, the difference was night and day, you could pull the line out with one hand and it didn’t take much force at all! It was great! I highly recommend this to ANYONE with an XRC winch.

Next up was the electrical stuff. Something that was pointed out to me by FlatBlak (http://www.expeditionportal.com/forum/showpost.php?p=595031&postcount=22) was the electrical ground terminal. This winch pulls a LOT of current (as all winches do) so you want to make sure all terminals have a good connection, however the factory ground terminal has the majority of its surface painted:

After some scraping and filing, I had a nice surface to contact with the lugs. I feel much better about this now:

Then I decided I wanted to protect the wires a bit better up front, while I used all marine grade cables, I decided to shield them just for good measure. I shielded all the cables and put a plastic grommet where they run through the front radiator support.

One last thing I noticed when taking it apart was that there was some SLIGHT surface rust on the bolt that holds the synthetic line to the drum. I am not sure if this is a big deal, but I decided to upgrade it to stainless just in case.

I feel much better about this winch now and feel it is ready to save my @$$ if I get into some trouble.