SONICMASD

Adventurer

7/13/19: Let's go back in time a bit because I never updated this thread with my final spare tire decision. If you recall, I tried the hack of flipping the spare tire carrier upside down to accommodate a 33" tire (32" is the max the stock set up will fit).

Yes, flipping the tire mount upside down does technically work but I'm not a fan of this hack and do not recommend it. First of all, the 33" spare barely fits, it's like almost rubbing the rear wiper arm:

Secondly, the mount when flipped is tilted so you will need to use washers on one side to help balance out the look. Here is what it looks like if you just flip it without washers:

Drive side - tire sits close to body:

Passenger side - tire has big gap between the body:

And thirdly, and most importantly - It's difficult to get the spare on and off. It was nearly impossible for me using a 31.5" Load E tire but the 33" tire is actually easier because you can rest it on the top of the rear bumper and just push it up a bit to line up the lugbolt hole. You lose the factory hook to hold up the spare so you can bolt it in place so it's a tricky procedure and I wasn't a fan.

Solution - But the spare tire mount back on the right way and buy a Chinese aftermarket copy of an OEM Mitsu Gen4 part made to raise the spare tire up.

You can find them all over ebay Australia. They aren't cheap at around $110 delivered but it's better than tearing apart the rear door to jerry rig the mount flip IMO.

I only have 3 small complaints with the thing but overall it's the best solution I've found so far short of spending a lot more money:

1. Is that it's Blue (will easily be fixed one day with spray paint)

2. It is too beefy! The thing is 3/8" steel plate which is way overkill to hold up a spare tire and it's damn heavy. 1/4 would have been just fine but I guess this is a good problem to have.

3. I wish they welded a hook on the top to hold up the spare and line up the wheel perfectly. Because right now, you've got to rest the wheel on the lugstuds which can mar them if you have a steel wheel, shouldn't be a problem for me with alloys but I guess I could in turn mar the lug nut holes in the wheels, though not too likely. The bigger thing is it's possible to wallow out your lugnut holes if you just put the wheel on the studs and go to town when tightening them down. You need to finger tighten them a little at a time to ensure the lugnuts center up the wheel straight.

But again, these are minor complaints and I'm very happy with this setup.

(yes, i put in two bolts/nuts through the bottom holes of the oem mount later)

Even gap behind tire:

Good rear wiper arm clearance:

Lots of space left with a 33, I think a 35 would fit:

I recently took up mountain biking as a hobby and my Yakima spare tire mount still works with this setup:

Yes, flipping the tire mount upside down does technically work but I'm not a fan of this hack and do not recommend it. First of all, the 33" spare barely fits, it's like almost rubbing the rear wiper arm:

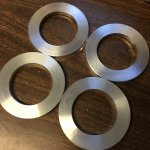

Secondly, the mount when flipped is tilted so you will need to use washers on one side to help balance out the look. Here is what it looks like if you just flip it without washers:

Drive side - tire sits close to body:

Passenger side - tire has big gap between the body:

And thirdly, and most importantly - It's difficult to get the spare on and off. It was nearly impossible for me using a 31.5" Load E tire but the 33" tire is actually easier because you can rest it on the top of the rear bumper and just push it up a bit to line up the lugbolt hole. You lose the factory hook to hold up the spare so you can bolt it in place so it's a tricky procedure and I wasn't a fan.

Solution - But the spare tire mount back on the right way and buy a Chinese aftermarket copy of an OEM Mitsu Gen4 part made to raise the spare tire up.

You can find them all over ebay Australia. They aren't cheap at around $110 delivered but it's better than tearing apart the rear door to jerry rig the mount flip IMO.

I only have 3 small complaints with the thing but overall it's the best solution I've found so far short of spending a lot more money:

1. Is that it's Blue (will easily be fixed one day with spray paint)

2. It is too beefy! The thing is 3/8" steel plate which is way overkill to hold up a spare tire and it's damn heavy. 1/4 would have been just fine but I guess this is a good problem to have.

3. I wish they welded a hook on the top to hold up the spare and line up the wheel perfectly. Because right now, you've got to rest the wheel on the lugstuds which can mar them if you have a steel wheel, shouldn't be a problem for me with alloys but I guess I could in turn mar the lug nut holes in the wheels, though not too likely. The bigger thing is it's possible to wallow out your lugnut holes if you just put the wheel on the studs and go to town when tightening them down. You need to finger tighten them a little at a time to ensure the lugnuts center up the wheel straight.

But again, these are minor complaints and I'm very happy with this setup.

(yes, i put in two bolts/nuts through the bottom holes of the oem mount later)

Even gap behind tire:

Good rear wiper arm clearance:

Lots of space left with a 33, I think a 35 would fit:

I recently took up mountain biking as a hobby and my Yakima spare tire mount still works with this setup:

Last edited: