DT75FLH

Adventurer

How about this for a gauge set.....

0-30psi electric fuel gauge, autometer Z-series, 2 1/16"

1600 degree pyrometer/egt, with prope, autometer Z-series, 2 1/16"

0-60psi, mechanical boost gauge, autometer z-series, 2 1/16"

They make a 0-15psi fuel gauge, but I figure it would be nice to have the ability to check for +20psi for injector pump front seal safety. I plan on running the low pressure piston pump soon, plus I have been looking at using the low pressure spring in the 2nd gen larger piston dia version. That is suppose to give tons of volume with safe rotary pump pressures.

I wish they made an electric boost gauge in this series, but running the line shouldn't be too big of a deal. I think having a boost gauge capable of handling future upgrades is good. I would like something with enough range to watch for the danger zone for head gaskets around 40psi in the future.

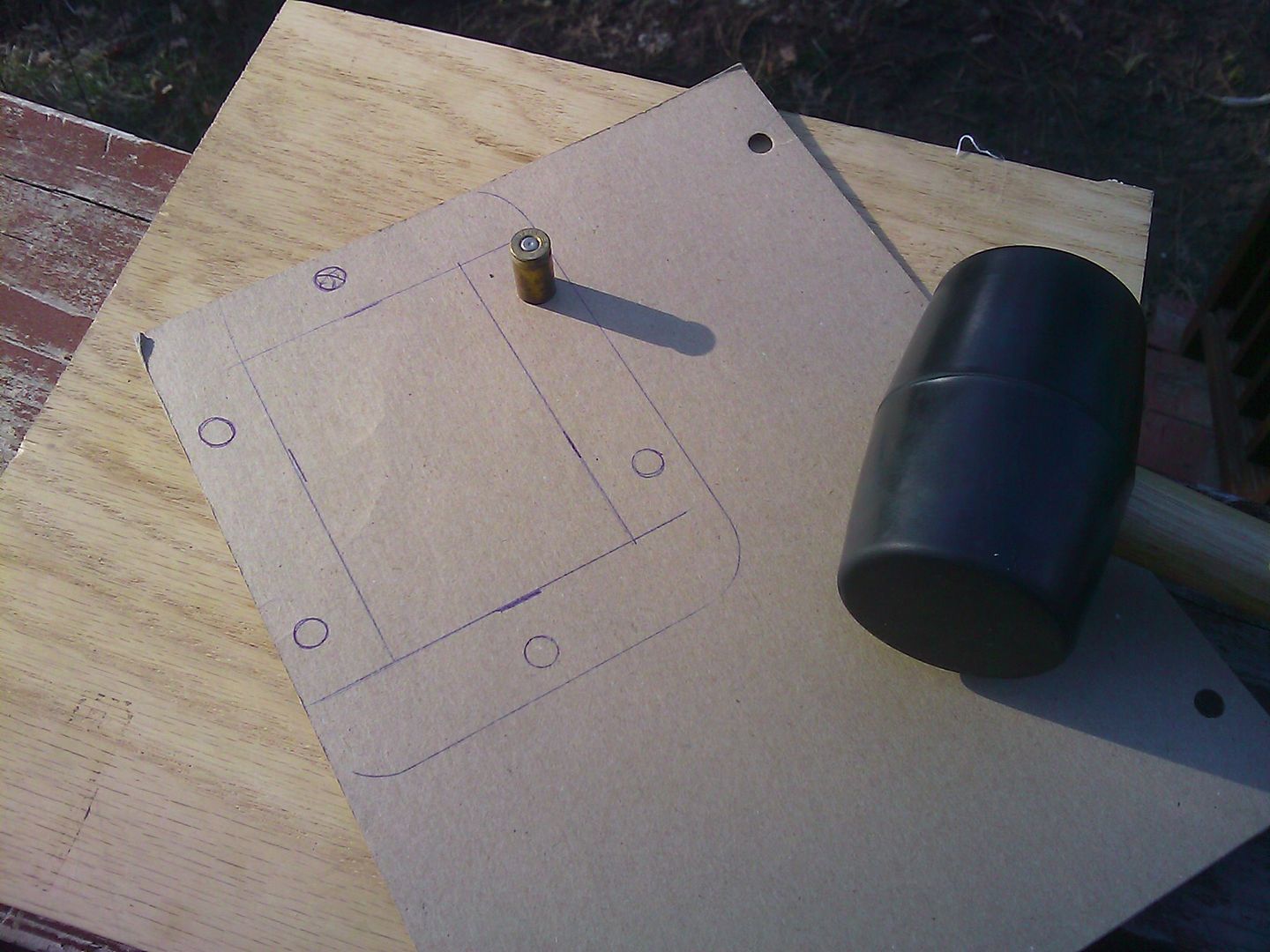

I will have to come up with something for mounting. I guess it might be time to try and make a pillar mount with some fiberglass. I just can't think of many other areas to mount the gauges that are basically in the line of sight and that doesn't require cutting the top of the dash up....

MMMMMmmmmm

I like the autometer gauges.

my last dodge I put on the typical tranny,egt,boost (auto meters had zero issues)..and ordering them through genos garage they threw in the 3 pod a piller mount for free.