Great looking build so far. Keep us updated as you continue tuning the coilovers.

Will do! Thanks!

Very nicely built 4runner. I like all the mods you have done.

Can you 'school' me on dual cases? Are you happy with your set-up? I am considering this mod on my 99 4runner, and have just started looking at the Marlin Crawler Taco Box set up. Is this similar to what you have?

Also, can you expound on the need for new lower control arms to fix the pinion angle?

If you don't want to 'muddy' your build thread you can PM me.

Thanks

Durwin

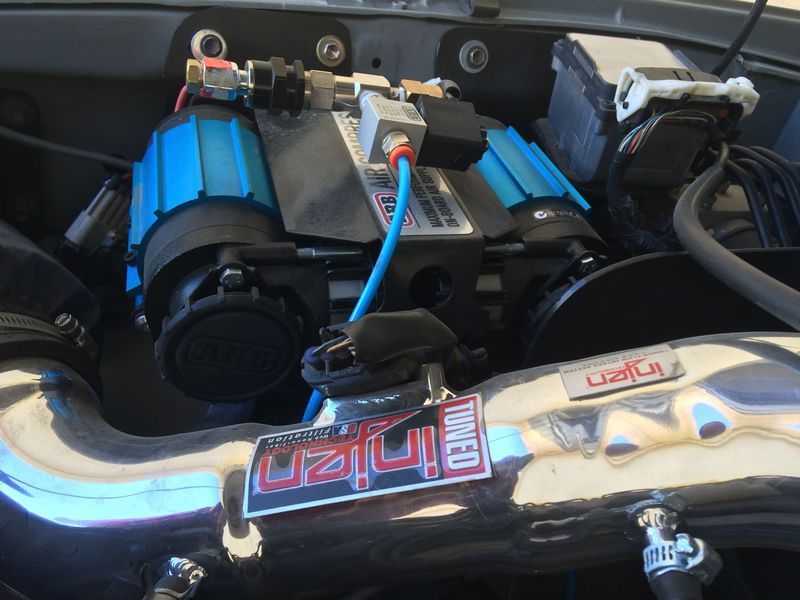

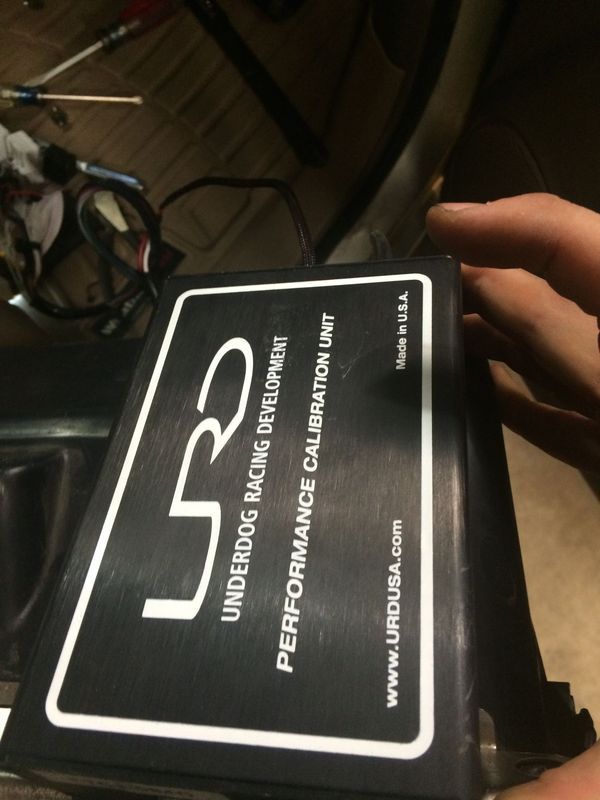

Thanks! As for the dual cases, yes, I have the exact same thing as the Marlin Box (my rear adapter is marlin, but the front is Inchworm, because Marlin was going to be out of stock for 6 months when I went to purchase mine).

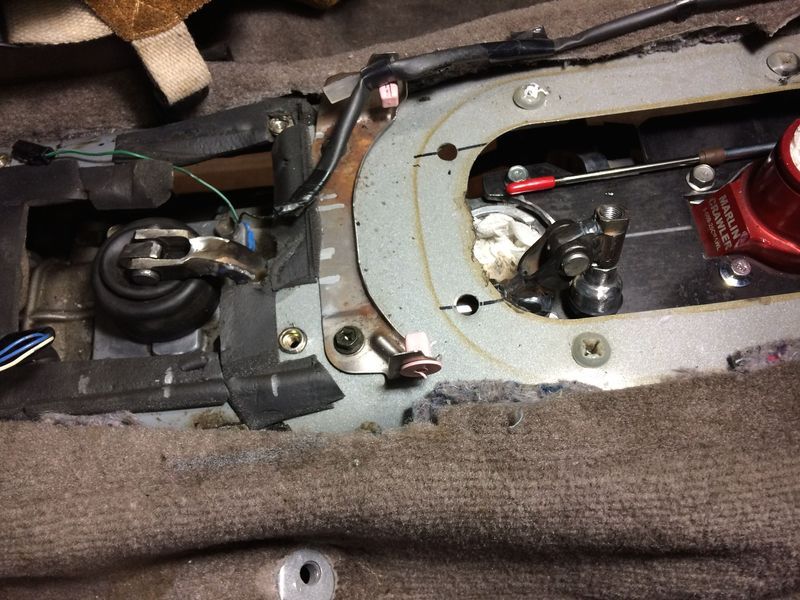

I am 99% happy. I am having trouble with the shifter leaking, despite trying several different shifters, bases, etc.. (this was before I did anything with the linkages, it has leaked since I put it in). I finally filled the whole shifter with FIPG before putting it together, and that has mostly stopped the leak. I saw a tad bit more leaking the other day, so I will investigate that still, but for the most part, its pretty good. Offroad, it is awesome. Lockers and dual cases are my all time favorite mods. I have had them on both of my trucks now, and I find them to be the best modifications you can make in terms of increasing the vehicle's capability.

The new arms are to adjust for the shorter drive shaft. The dual case set up pushes your stock transfercase about 8" or so backwards. So you have to have your front driveshaft lengthened, and the rear shortened.

Because the rear shaft has a double cardan joint at the transfercase end, and a single u-joint at the differential, the u joint must be straight.

The double cardan is a CV joint and therefore conserves angular velocity through the joint, even at an angle (hence the CV, or constant velocity, classification).

The single u joint does not. If a shaft has a non-CV joint, such as a ujiont in it, in order to conserve angular momentum, it must either be straight (no angle), or have a second non-CV joint at an equal and opposite angle somewhere else in the shaft. Without either of these two things, a force is exerted on the spinning shaft and this will cause vibrations, which ultimately ruin bearings and things.

By moving the transfercase back, the differential was pointed slightly down, causing the u-jointed end of the shaft to have a few degrees of angle in it. I added the new, shorter lower links, which served to tip the flange of the differential up, putting the ujoint back at zero angle.

Hopefully that makes sense. Cheers!