You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2022 Ford F550 - DIY - Adventure Expedition Vehicle Build Thread

- Thread starter Vance Vanz

- Start date

Vance Vanz

Well-known member

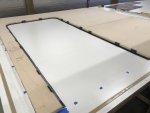

Resin Infusion – Back Wall – Layup

The Final Product - Total Dimensions: 87-7/8" W x 85" H Panel (Door opening roughly 34-3/4" W x 71.5" H)

My Easy Bake Oven and a peek underneath, patiently waiting for all of the dry spots to infuse

Peel Ply Side:

Layup Table Side:

Technical info from the layup for those that are interested:

The Final Product - Total Dimensions: 87-7/8" W x 85" H Panel (Door opening roughly 34-3/4" W x 71.5" H)

My Easy Bake Oven and a peek underneath, patiently waiting for all of the dry spots to infuse

Peel Ply Side:

Layup Table Side:

Technical info from the layup for those that are interested:

- 3 gallons of epoxy was used for the layup

- Just under 2 hours for the layup

Last edited:

Vance Vanz

Well-known member

Carbon Fiber - Back Wall - Dry Fit & Bonding/Filleting

(Up, mark, down sand. Up, mark, down sand, Up, mark, down sand) x 2 and finally done.

It took a little time to: build a jig for the top of the wall, figure out how I was going to set the wall in place by myself while the sides and bottom were wet out with resin and to figure out how I would be able to hold in place and tighten 50 inch clamps by myself with one hand, while having to push the back wall in at the same time (to get it square with the side wall) occupying my other hand.

FYI: If anyone needs an affordable DIY dust collection system with a variety of adaptors, I would recommend this one. Works with a basic Rigid shop vac and I haven't comes across a tool yet that one of the adaptors doesn't fit.

Amazon product ASIN B0849L6LLH

Another late night/long weekend, but she is bonded, filleted and peel plyed.

I'll give it a couple of days for the back wall to cure enough and then the roof panel will go up for dry fitting and bonding ?. There just may be some light shining at the end of this LOOOOOOOOOOOOOONG tunnel ??!

(Up, mark, down sand. Up, mark, down sand, Up, mark, down sand) x 2 and finally done.

It took a little time to: build a jig for the top of the wall, figure out how I was going to set the wall in place by myself while the sides and bottom were wet out with resin and to figure out how I would be able to hold in place and tighten 50 inch clamps by myself with one hand, while having to push the back wall in at the same time (to get it square with the side wall) occupying my other hand.

FYI: If anyone needs an affordable DIY dust collection system with a variety of adaptors, I would recommend this one. Works with a basic Rigid shop vac and I haven't comes across a tool yet that one of the adaptors doesn't fit.

Amazon product ASIN B0849L6LLH

Another late night/long weekend, but she is bonded, filleted and peel plyed.

I'll give it a couple of days for the back wall to cure enough and then the roof panel will go up for dry fitting and bonding ?. There just may be some light shining at the end of this LOOOOOOOOOOOOOONG tunnel ??!

Last edited:

Vance Vanz

Well-known member

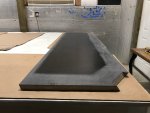

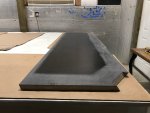

Carbon Fiber - Roof - Dry Fitting & Final Cuts

I had an extra set of hands helping me most of last week, but I can't believe how long it took to get the roof: prepped, up, dry fitted, and blocked for bonding.

Roof sanded and prepped.

Getting the roof up with two people on the first try was easier than I thought it would be. It felt about 135-150 lb's I'm guessing.

The final cut on the exterior walls of the camper felt good.

I had an extra set of hands helping me most of last week, but I can't believe how long it took to get the roof: prepped, up, dry fitted, and blocked for bonding.

Roof sanded and prepped.

Getting the roof up with two people on the first try was easier than I thought it would be. It felt about 135-150 lb's I'm guessing.

The final cut on the exterior walls of the camper felt good.

Last edited:

Vance Vanz

Well-known member

Carbon Fiber - Roof - Dry Fitting & Blocking

Supports prior to the roof going up.

Checking for any/all gaps between the side walls and the roof, as well as between the angle cuts in the roof panels. Everything was smoothed and leveled out to fit nice and snug.

Blocking to help get the roof on, in place and raised for bonding.

Supports prior to the roof going up.

Checking for any/all gaps between the side walls and the roof, as well as between the angle cuts in the roof panels. Everything was smoothed and leveled out to fit nice and snug.

Blocking to help get the roof on, in place and raised for bonding.

Last edited:

Vance Vanz

Well-known member

Carbon Fiber - Roof - Bonded

It's pretty rough looking and still needs a sanding and final light structural fairing before tabbing, but the exterior of the camper is finally completely bonded.

Another long day and late night last week to get the roof all pookied up, clamped down, set perfectly in place, filleted/faired and peel plyed. During placement and clamping, keeping the roof panels angled cuts tight, while also getting the side walls to stay at exactly 90"s wide all the way down the camper, took some finesse and patience. Sounds pretty simple, but when everything is wetted out with thickened epoxy, things love to slide around until you get them tightly compressed and/or a few clamps on things.

This week has been sizing and cutting all the remaining tabbing for the interior and exterior. Although tabbing doesn't seem like much work, there is a lot of it and it all has to be placed and set perfectly since most of my interior/exterior tabbed edges/corners will finished/visible surfaces.

It's pretty rough looking and still needs a sanding and final light structural fairing before tabbing, but the exterior of the camper is finally completely bonded.

Another long day and late night last week to get the roof all pookied up, clamped down, set perfectly in place, filleted/faired and peel plyed. During placement and clamping, keeping the roof panels angled cuts tight, while also getting the side walls to stay at exactly 90"s wide all the way down the camper, took some finesse and patience. Sounds pretty simple, but when everything is wetted out with thickened epoxy, things love to slide around until you get them tightly compressed and/or a few clamps on things.

This week has been sizing and cutting all the remaining tabbing for the interior and exterior. Although tabbing doesn't seem like much work, there is a lot of it and it all has to be placed and set perfectly since most of my interior/exterior tabbed edges/corners will finished/visible surfaces.

Last edited:

Vance Vanz

Well-known member

Pass Through - Additional LH 40 Seat

While the epoxy was drying for the roof layup, I was able to shift gears a bit and do a little work on the seat for the pass through/crew cab area.

Before I start........., I must have an UN-lucky rabbits foot somewhere in my pocket that I'm not aware of. My last order was the oversized door for the MTB/Gear locker and it was a complete fiasco (I have had several of these experiences now on the build). The very next thing I ordered was a used seat from a wrecking yard. We are talking ty rear 40 seat out of a 2019 or newer Ford F-150 or super duty truck. The only thing I needed was the steel frame, nothing else off of the seat. The thing could have been drug through the mud or torn up by a grizzly bear for all I care ?. There are hundreds of them out there. I was told "4 days, no problem" and it took three screw ups/wrong seats and three and a half weeks after the fact. A total of basically a month before I finally got the seat.

ty rear 40 seat out of a 2019 or newer Ford F-150 or super duty truck. The only thing I needed was the steel frame, nothing else off of the seat. The thing could have been drug through the mud or torn up by a grizzly bear for all I care ?. There are hundreds of them out there. I was told "4 days, no problem" and it took three screw ups/wrong seats and three and a half weeks after the fact. A total of basically a month before I finally got the seat.

We are not talking about COVID related supply chain issues here, these are businesses simply not getting it, or even worse, not caring when they do make a mistake. Somebody please tell me I'm not the only one having so many vendor/shipping issues. This is becoming the crappiest part of the build ?? !

!

OK, time to get off my soap box and get back to providing expedition build information ?.

?.

From Ford: I have a 2022, so any 2019 or newer F-150 or super duty 40 rear seat will have the same bottom and top steel frame for the existing 40 seat in my truck. So......, I went shopping for a 2019 40 seat in an F-150, easiest to find and cheapest. Since I only needed the frame, I didn't care what color, cloth, or condition of the cloth/cushions. The only thing I cared about was the frame not being rusted, or too rusted. I had the wrecking yard grab the cheapest seat on a truck that just came in, 10 days or less. This way the truck would probably still have the doors on it and the seat would not have been exposed to the elements, therefore causing the steel frame of the seat to be rusted/excessively rusted. Plan worked.

I stripped the used 40 seat completely down, as well as my new 60 seat, to ensure everything lined up/could be taken off of the new 60 seat and put onto the used 40 seat frame.

Here is what I found:

That's it, pretty simple for a new, all factory, LH 40 seat that you can't buy and also perfectly matches the RH 40 seat. The price point will also be far less than most/any comparable aftermarket 40/jump seat, or installing two Ford factory captains chairs in the back. I also landed an upholster today and the seat should be done in 2-4 weeks for a very reasonable price.

FYI: if you go this route and upholstery shops are looking at you like you are crazy, or are quoting you $1,500-2,000, keep looking. The first 4 shops I went to were intimidated and/or didn't want the work (supper high quotes), but once I found a few good auto upholsters, it was no problema!

I'm going to be super detailed about the crew cab/pass through on this build, because it is one of those areas I could not find much information on when I was doing all of my research. it is also something some people avoid and/or are intimidated by, because the lack of information. Hopefully I can save someone hours, if not days of research and headaches if they decide to take the larger pass through plunge.

All I ask, if you find this detailed information helpful and use it in your build, is to come find me somewhere in Central and/or South America and by me una cervaza Senor or Senora ☺!

More pass through shenanigans to come as the process unfolds.

Time for , there's miles of tabbing to do this week!

, there's miles of tabbing to do this week!

While the epoxy was drying for the roof layup, I was able to shift gears a bit and do a little work on the seat for the pass through/crew cab area.

Before I start........., I must have an UN-lucky rabbits foot somewhere in my pocket that I'm not aware of. My last order was the oversized door for the MTB/Gear locker and it was a complete fiasco (I have had several of these experiences now on the build). The very next thing I ordered was a used seat from a wrecking yard. We are talking

We are not talking about COVID related supply chain issues here, these are businesses simply not getting it, or even worse, not caring when they do make a mistake. Somebody please tell me I'm not the only one having so many vendor/shipping issues. This is becoming the crappiest part of the build ??

OK, time to get off my soap box and get back to providing expedition build information

From Ford: I have a 2022, so any 2019 or newer F-150 or super duty 40 rear seat will have the same bottom and top steel frame for the existing 40 seat in my truck. So......, I went shopping for a 2019 40 seat in an F-150, easiest to find and cheapest. Since I only needed the frame, I didn't care what color, cloth, or condition of the cloth/cushions. The only thing I cared about was the frame not being rusted, or too rusted. I had the wrecking yard grab the cheapest seat on a truck that just came in, 10 days or less. This way the truck would probably still have the doors on it and the seat would not have been exposed to the elements, therefore causing the steel frame of the seat to be rusted/excessively rusted. Plan worked.

I stripped the used 40 seat completely down, as well as my new 60 seat, to ensure everything lined up/could be taken off of the new 60 seat and put onto the used 40 seat frame.

Here is what I found:

- The 60 seat cushions can be cut and re-spliced/glued together to get an exact mirror of the RH 40 seat-No extra foam needed and you will have the seat belt notch on the correct side.

- Almost all of the existing seat cloth can be unstitched and spliced/re-sewn to get an exact mirrored match to the RH 40 seat. I believe there will only be two small pieces of new cloth needed-will know for sure once a professional upholster has completed the work.

- The mounting base plate on the top frame of the 60 seat, for the latch on the rear of the seat, will need to be ground/cut off and re-welded to the 40 seat about (3/8-5/8") in (towards the center of the seat) from where it was located on the 60 seat frame.

- The lower welded nut on the bottom frame of the 40 seat will need to be removed and re-welded to the other side of the seat frame, or the one on the 60 seat frame can be taken off and re-welded/used on the 40 seat frame. Or, you can purchase and weld a brandy new one on if that tickles your fancy.

- The double radius steel rod on the bottom seat frame can be removed (swapped with the single radius rod on the other side) and re-welded to the opposite side of the the 40 seat, or you can use the one off of the 60 seat. Not required, but does help prevent the door side corner of the seat from prematurely sagging down. (I'm a detailed kinda guy, so I gotta do it

)

)

- The two unthreaded pilot holes on the base frame of the 40 seat, need to be tapped to match those on the right. These are for the plastic cover that will get mounted on the opposite side of the seat frame after the feet from the 60 seat are mounted to the 40 seat.

That's it, pretty simple for a new, all factory, LH 40 seat that you can't buy and also perfectly matches the RH 40 seat. The price point will also be far less than most/any comparable aftermarket 40/jump seat, or installing two Ford factory captains chairs in the back. I also landed an upholster today and the seat should be done in 2-4 weeks for a very reasonable price.

FYI: if you go this route and upholstery shops are looking at you like you are crazy, or are quoting you $1,500-2,000, keep looking. The first 4 shops I went to were intimidated and/or didn't want the work (supper high quotes), but once I found a few good auto upholsters, it was no problema!

I'm going to be super detailed about the crew cab/pass through on this build, because it is one of those areas I could not find much information on when I was doing all of my research. it is also something some people avoid and/or are intimidated by, because the lack of information. Hopefully I can save someone hours, if not days of research and headaches if they decide to take the larger pass through plunge.

All I ask, if you find this detailed information helpful and use it in your build, is to come find me somewhere in Central and/or South America and by me una cervaza Senor or Senora ☺!

More pass through shenanigans to come as the process unfolds.

Time for

Last edited:

StenchRV

Well-known member

Carbon Fiber - Roof - Bonded

It's pretty rough looking and still needs a sanding and final light structural fairing before tabbing, but the exterior of the camper is finally completely bonded.

Another long day and late night last week to get the roof all pookied up, clamped down, set perfectly in place, filleted/faired and peel plyed. During placement and clamping, keeping the roof panels angled cuts tight, while also getting the side walls to stay at exactly 90"s wide all the way down the camper, took some finesse and patience. Sounds pretty simple, but when everything is wetted out with thickened epoxy, things love to slide around until you get them tightly compressed and/or a few clamps on things.

View attachment 761547View attachment 761545View attachment 761546View attachment 761544View attachment 761550View attachment 761548View attachment 761549

This week has been sizing and cutting all the remaining tabbing for the interior and exterior. Although tabbing doesn't seem like much work, there is a lot of it and it all has to be placed and set perfectly since most of my interior/exterior tabbed edges/corners will finished/visible surfaces.

LOOKING AWESOME!!

CHEERS!!

Vance Vanz

Well-known member

Hey ITTOG!Everything is looking great. Excellent work. Can you remind me what tabbing is? I know you explained it a while back but I couldn't find it.

Thanks for the support ?? and for the question.

Tabbing is the carbon fiber cloth that is used to wrap/overlay all of the corners/joints between the different carbon fiber panels/pieces. It’s the structural support to ensure the filleted/faired joints don’t crack/come apart.

I believe I posted the layup schedule for the tabbing, layers of CF cloth, already. If not, and if someone is interested, just let me know.

Vance Vanz

Well-known member

Thanks Craig!LOOKING AWESOME!!

CHEERS!!

I’m still waiting for that unexpected burst of energy, where I spontaneously break out into my first Dance party in the camper ???!

I’ll keep you posted ?.

Vance,

I wish I had found this thread sooner; it would have been cool to lend a hand and see the panels being infused. I have very basic composite experience and do not envy your chosen method of construction, though I am certain the final product will be top notch.

I wish I had found this thread sooner; it would have been cool to lend a hand and see the panels being infused. I have very basic composite experience and do not envy your chosen method of construction, though I am certain the final product will be top notch.

Last edited:

Vance Vanz

Well-known member

I wish you would have found the thread sooner as well ?. Help is always welcome on Ultra Marathon projects like these.Vance,

I wish I had found this thread sooner; it would have been cool to lend a hand and see the panels being infused. I have very basic composite experience and do not envy your chosen method of construction, though I am certain the final product will be top notch.

Maybe you can find me when I return from my trip and build a house

Yah, once you decide to vacuum bag and/or infuse, you are in for a long haul-especially with a larger size camper/habitat box.

It's too late to cut corners now; I gotta make sure this thing finishes off top notch. If not, I'd just be throwing money away. No pressure of course.

Thanks for touching base!

Vance Vanz

Well-known member

Pass Through - Additional LH 40 Seat - Frame Additions

All of the needed/previously noted additions and modifications for the metal work on the 40 seat frame are complete:

Dry Fitted

Wire wheel and paint to get it looking new and ready for the upholster

We'll see what it looks like when I get the finished/upholstered seat back ?.

All of the needed/previously noted additions and modifications for the metal work on the 40 seat frame are complete:

Dry Fitted

Wire wheel and paint to get it looking new and ready for the upholster

We'll see what it looks like when I get the finished/upholstered seat back ?.

Last edited:

Vance Vanz

Well-known member

Door Fitting

Dry fitting of the back door to make sure it fits-all is good.

Installing/bonding the conner radius pieces in the step box for the entry door.

Dry fitting of the back door to make sure it fits-all is good.

Note: The bottom side edge of the door still needs to be sanded smooth. This is where I previously cut part of the door trim off.

Installing/bonding the conner radius pieces in the step box for the entry door.

These will get additional layers of CF over them when the tabbing occurs on the outside of the camper, so they match the rest of the door fame/become structurally sound.

Last edited:

Similar threads

- Replies

- 5

- Views

- 401

- Replies

- 25

- Views

- 2K

- Replies

- 10

- Views

- 877

- Replies

- 2

- Views

- 533

- Replies

- 0

- Views

- 790