Composting Toilet Layout - Feedback Welcomed!

During the previously noted final mechanical systems layout, I had to pull the trigger and decide where and how I was going to vent the composting toilet. Since aesthetics are a priority on this build, the big old vent line needs to be handled in a discreet way.

I had three options for running/terminating the vent line: #1 the roof above/adjacent to the shower #2 the back wall of the shower/back side of camper-left side #3 the side wall of the shower/driver's side, rear side wall of camper.

#1 would have required running the vent line vertically and visibly up the entire height of the inside of the shower (not a visually pleasing option for me) or running it through the adjacent wall, into the vertical closet, and up the entire height of the closet (not an option considering I would have had to blank off the entire back side of the vertical cabinet/or a corner portion of it and lose a ton of valuable storage space).

#2 very short vent line run and hidden behind the toilet, but this would put the vent termination at the bottom of the access ladder to the roof and very close to the gear storage locker door on the back side of the camper, at chest height. I did not want to smell any poo when gearing up for fun adventures.

#3 seemed like the best bet. A short vent line, only somewhat visible on the side of the toilet, and I will rarely be around the driver's side rear area of the camper.

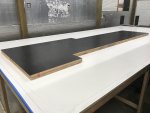

So here is how I have decided to condense the very long and oversized fittings they give you with the toilet. I'm actually surprised, maybe even shocked, that they do not have a simpler and more condensed venting system given the number of RV's and boats these things go in, therefor confined spaces.

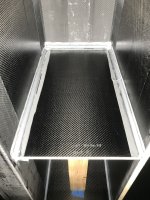

I have about 7-1/2" from the side of the toilet to the side walls when the toilet is centered. This will probably shrink to max 7-1/4" once the finished shower walls/shower pan go in.

View attachment 779370

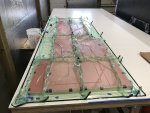

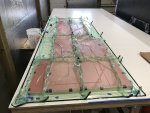

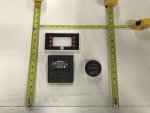

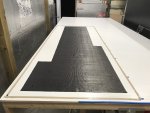

With all of the fittings the factory wants you to put in, the shortest distance you can manage, in a straight shot, (from the adapter that mounts to toilet to the outside/gasket edge of vent fan) is about 11-1/2"

View attachment 779371

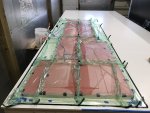

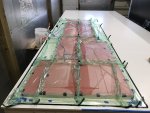

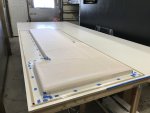

As opposed to hard piping this thing and using a union, I decided to use the factory items to try and keep things simple and still, literally, flexible. I/you can get everything piped in, in a straight line, at the shortest distance of about 5-1/2"

View attachment 779372

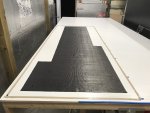

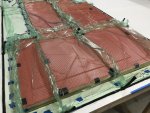

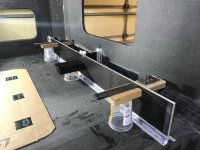

I removed the vent line coupling that also houses the bug screen. The bug screen can be installed in the end of the fitting that mounts directly to the toilet. It fits in the end very nicely/snuggly and can even be siliconed in a few places to make sure it stays put. The screen would also be accessible for cleaning it if/when needed.

View attachment 779367

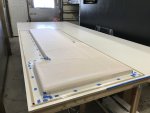

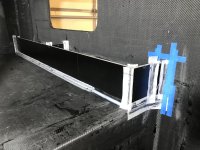

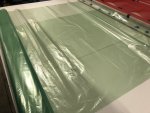

Here is what it will look like installed

View attachment 779365View attachment 779366

The fitting that connects to the toilet spins freely within the toilet, and is threaded to receive the threaded vent hose, so this will act as the union/mechanism to remove the vent line from the top portion of the toilet when it is time to clean the toilet. I can just spin the fitting to unthread the short piece of vent line.

Electrical for the fan. Since I'm running some kind of FRP shower panel and it will be held off the wall ever so slightly for caulking/the bonding material, I will run the wires in between the FRP panel and side wall. My wall is 1-1/8" thick, the FRP and space for bonding will probably be 1/8-3/16" and the vent fan is set back about a 1/4" in the termination housing, so this gives about 1-1/2" inside the wall for wire connectors. I will also install an additional screen on the inlet side of the fan to prevent the electrical wires/wire connectors from sliding back into the fan/fan blades.

Anyone that has a composting toilet and has tried something similar, and it did not work, or can see a flaw in my plan, please chime in. This should work and be fairly straight forward, but I want to make sure that I'm not missing something very obvious, or missing something that would cause an issue and only be discovered by those that have actually tried something similar

Also, if you have done something similar and it works great, give me the reassuring thumbs up.

Any recommendations on preferred side wall termination caps would be great as well ?. I haven't had the time to research any yet.

?. This is usually not the case for me)

?. This is usually not the case for me)