Wow; it has been over a month since I last posted. Sorry everyone.

I hope everybody had a good 4th.

Lets start with a

Humanness Check In......

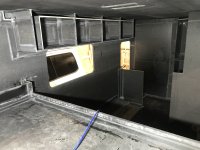

I have been grinding away on the build non stop every day and more importantly, the build has been grinding on me 24/7. I'm mentally, emotionally and physically beat. I just keep putting one foot in front of the other, inch by inch, trying to get the composite work done. I'm am running off of pure will power right now; the grittiest of grit!

It is super hard being relatively close to the end of the composite work, and wanting to see this thing come back from paint, but still having so much composite work left to do. The final interior and exterior punch list items for the composite work are just taking forever to wrap up. The amount of time that goes into some of these remaining composite projects is mind boggling, literally almost incomprehensible at times.

If this was a fight, my AZZ is getting dragged around the floor

.

Now back to our regularly scheduled program.