Vance Vanz

Well-known member

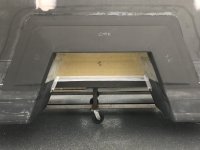

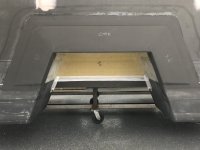

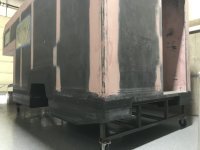

Bonding Fairings & Rear Fenders to the Camper

So, my sweet heart was in town visiting me for a few days and she called me one evening while I was at the shop working away. She asked if I needed any help. I said sure (as I had been prepping all day in order to bond the fairings) and I asked her if she was ready to work her butt off. She thought I was kidding and she also forgot to mention that she was referring to helping out "tomorrow" meaning the next day. Just a little relational miss communication ! I promise, we actually do pretty good in this department.

! I promise, we actually do pretty good in this department.

Regardless, she came out pretty late in the evening and I was stoked to have an extra set of hands to bond all four of the fairings. I kicked into go mode and the next thing you know it was 2am in the morning and she was basically turning into a puddle (we had both already worked a full day before starting all of this madness at 9pm). As soon as the last fairing was secured at about 2:30am, she tapped out and headed home. I stayed to get all of the filler smoothed out and peel plied. Another all nighter on this yahoo of a project

!

!

Erin, you are an Angel and a trooper

and a trooper  . I owe you BIG time sweetness

. I owe you BIG time sweetness

.

.

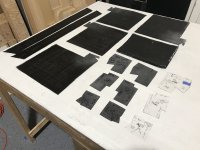

After sanding all of the joints on the fairings, it was filler coat number two for the fairing joints and time to bond the core material for the rear fenders.

One more sand on everything and some last little spot fills. Oh man, there is nothing fast about composite work.

So, my sweet heart was in town visiting me for a few days and she called me one evening while I was at the shop working away. She asked if I needed any help. I said sure (as I had been prepping all day in order to bond the fairings) and I asked her if she was ready to work her butt off. She thought I was kidding and she also forgot to mention that she was referring to helping out "tomorrow" meaning the next day. Just a little relational miss communication

Regardless, she came out pretty late in the evening and I was stoked to have an extra set of hands to bond all four of the fairings. I kicked into go mode and the next thing you know it was 2am in the morning and she was basically turning into a puddle (we had both already worked a full day before starting all of this madness at 9pm). As soon as the last fairing was secured at about 2:30am, she tapped out and headed home. I stayed to get all of the filler smoothed out and peel plied. Another all nighter on this yahoo of a project

Erin, you are an Angel

After sanding all of the joints on the fairings, it was filler coat number two for the fairing joints and time to bond the core material for the rear fenders.

One more sand on everything and some last little spot fills. Oh man, there is nothing fast about composite work.

Last edited: