Composite Labor Hours:

I'm always surprised by how long composite work takes

. Even though I've been at this composite work for a bit now, it still takes longer than I estimate.

When doing initial composite research, for this project, I couldn't find much info on the actual time frames (total labor hours) of the various projects I was researching.

For those interested, I did track the number of days/hours related to the work I recently did on the interior vertical walls. I didn't clock in and out each day to the minute, so these total times could be max 3-4 hours over or under. I'm figuring 12 hours per each work day.

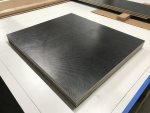

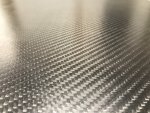

Cutting, notching, dry fitting, sanding, cleaning, bonding, leveling/squaring, filleting and peel plying all of the internal vertical walls: 5.5 days, 66 hours

Sanding/cleaning all filleted joints/adjacent walls, cutting/dry fitting all carbon fiber cloth/peel ply, and cutting plastic to wet out cloth for some of the tabbing (Note: I was also taking the time to use scrap materials when I could). 5 days, 60 hours

Mixing resin, wetting out material, tabbing, rolling out tabbing and peel plying all joints: 3.375 days, 40.5 hours

Now most of the tabbing is visible (will be a finished wall), so I am taking my time to ensure it is being laid up smoothly, but it is hard to wrap my head around 166.5 hours to get the internal walls bonded and tabbed.

I'm gonna say it, composite work can be brutal, brutal in the amount of time it takes.

I'm not trying to deter anyone from composite work, but if you embark down this path, you better have a crew to help you , or if working solo-be ready to work your AZZ completely off

!

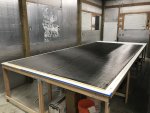

See you when the next resin infusion layup is complete.

. Even though I've been at this composite work for a bit now, it still takes longer than I estimate.

. Even though I've been at this composite work for a bit now, it still takes longer than I estimate. !

!