Vance Vanz

Well-known member

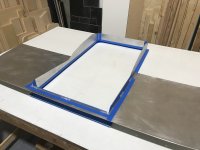

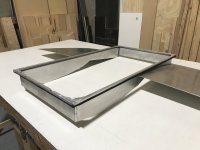

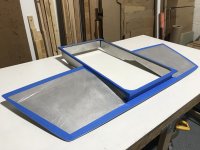

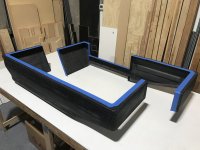

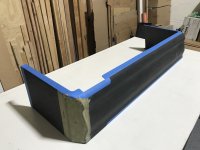

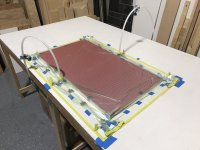

Glad somebody can relate to the process and pain30 years ago I used to build and repair patterns for foundry sand casting. There was a lot of Bondo work involved. All those swept and sanded fillets. Woof! Getting them right in the corners is tricky business.

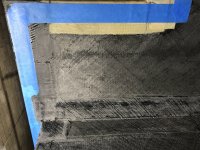

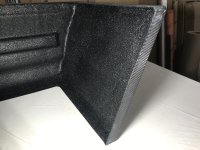

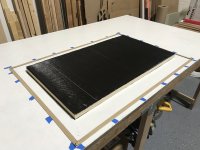

It did take a ton of time to get all of the corners/radiused fillets transitioned into the walls-ever so smoothly. I had to make various length 7/16" diameter dowels and wrap them in adhesive-backed-sand paper as my sanding tool. Sanding with a 7/16" diameter object for 4-5 days, gives the fingers a great workout and they even start to go numb a bit. The inside back corners, where all the corners of the cabinet meet......., Woof!, you just have to sand those with the tip of a finger. I burnt through about 12 pairs of work gloves doing all this.

Good times