Rear bumper design

Well guys and gals..... the last few weeks have been an absolute whirlwind of activity. I made the crazy decision to try and get the rig done enough (in my opinion) to roll to the Overland Expo. A friend of mine who used to work on our Rally car team became a rep. for Engel Fridge/Freezers, and he said if my rig would be done that he would have it placed in the Engel booth at the show. That was motivation enough to spend every waking moment not doing my regular job working on the Jeep to prepare it for the show. So I elected to slack on the posting, and fire up the fab shop every night at 6pm, and run until I couldn't run anymore. This entailed lots of Dubstep at rediculous volume (sorry to neighbors), RedBull and the help of a few good friends to make it come to fruition.

At this point we have already done 6 days in the vehicle, and man oh man are we pleased with the results. Like any vehicle the laundry list of things to do is ever growing, but that will have to come in later posts. First, I wish to bring you up to speed with the progress. Keep in mind that I was much less focused on taking photos, and way more focused on just getting the job done, so you will have to excuse the night photos when I get there, I am not terribly good at taking photos at 3 or 4 in the morning lol.

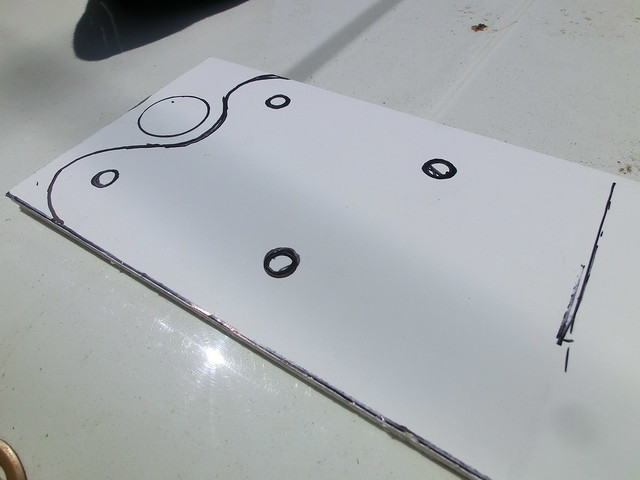

When we left off before, we had completed the front bumper design, and were just starting to lay out the rear bumper. I grabbed the foam core board and the razor, and started dreaming up a design

First things first though, I have to remove the factory bumper and mounts...

This turned into a serious PITA, and I had to use this...

To heat and remove these...

so I could get these off...

Anyone who owns a ZJ knows the fuel filler goes through the "frame" just in front of these nuts on the drivers side, so It was likely one of the most sketchy things I have done in years in my fab shop. I of course added tons of heat shielding before shoving the rose bud down the frame rail, but it scared the bejesus out of me regardless. Finally the brackets and hitch were off!

The next step was to open up the holes in the rear of the frame, and make room for the brackets

so out comes the die grinder or cut off wheel and the sparks were flying once again.... the holes were opened and ready for a mock up bracket

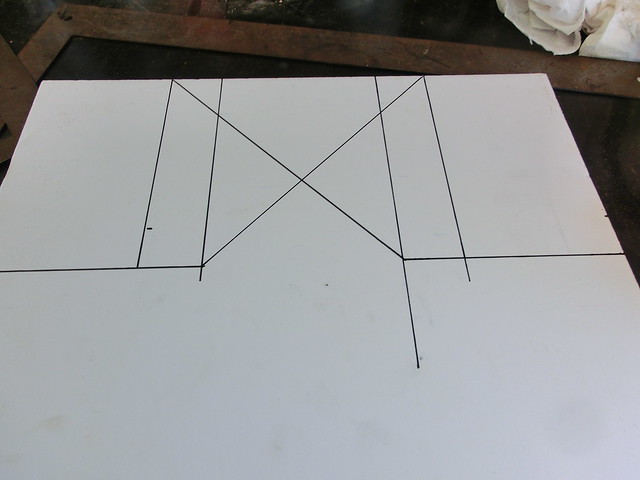

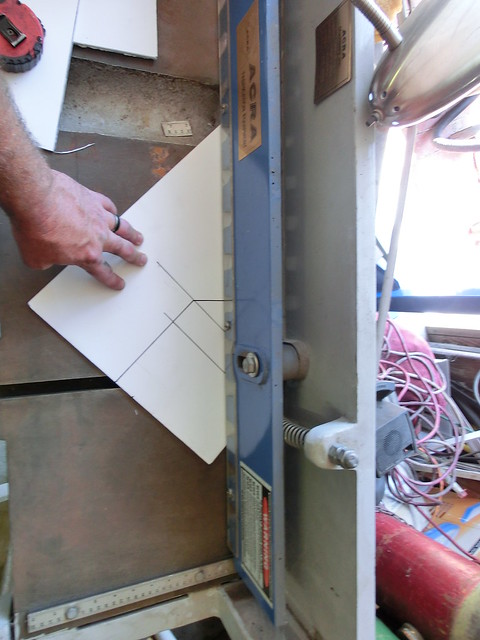

I decided to do some flat brackets on the bottom that would bolt through the stock holes as well as some verticle brackets that I would eventually weld to the flat bottom plates, and bolt through from the side. I wanted more than just 2 bolts per side, especially with a sparte tire carrier planned for this bumper. I did some figuring of angles, and sheered up the vertical brackets and put them in place

I used the RC Car tire foams to keep them snug against the side of the frame so I didnt have to drill them and bolt them in for now

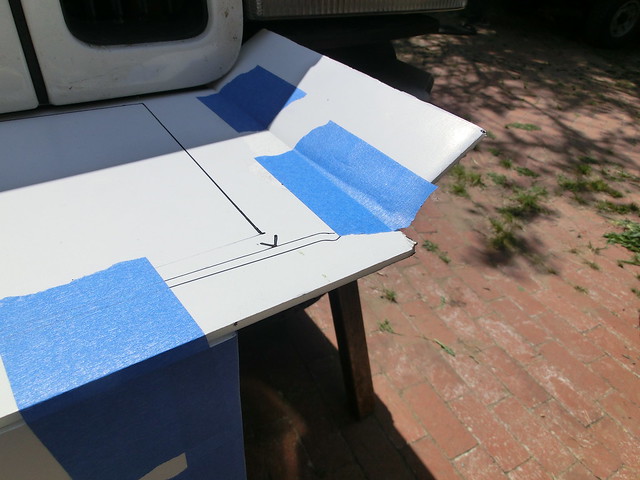

At last, I was to the fun part, a blank canvas, time to get creative!