Oman4x4

Laurie Bridger

Today's update... all the frame and suspension work is sandblasted and off for coating... can't wait to take pictures of it re-assembled and sitting on it's wheels.

The body is also being prepped for paint... but we have one last body modification to finish up - a little enhancement to the hood. The vents are from a 2014 Mustang GT and we plan to recess them so they sit flush exactly as they would on the Mustang, so the plan is to make a series of templates that will show the area to cut out and the area to recess. First template will be a rough-cut to relieve the tension on the metal, then there will be another template for the final cut marks to ensure the clips all bite properly.

The vents are from a 2014 Mustang GT and we plan to recess them so they sit flush exactly as they would on the Mustang, so the plan is to make a series of templates that will show the area to cut out and the area to recess. First template will be a rough-cut to relieve the tension on the metal, then there will be another template for the final cut marks to ensure the clips all bite properly.

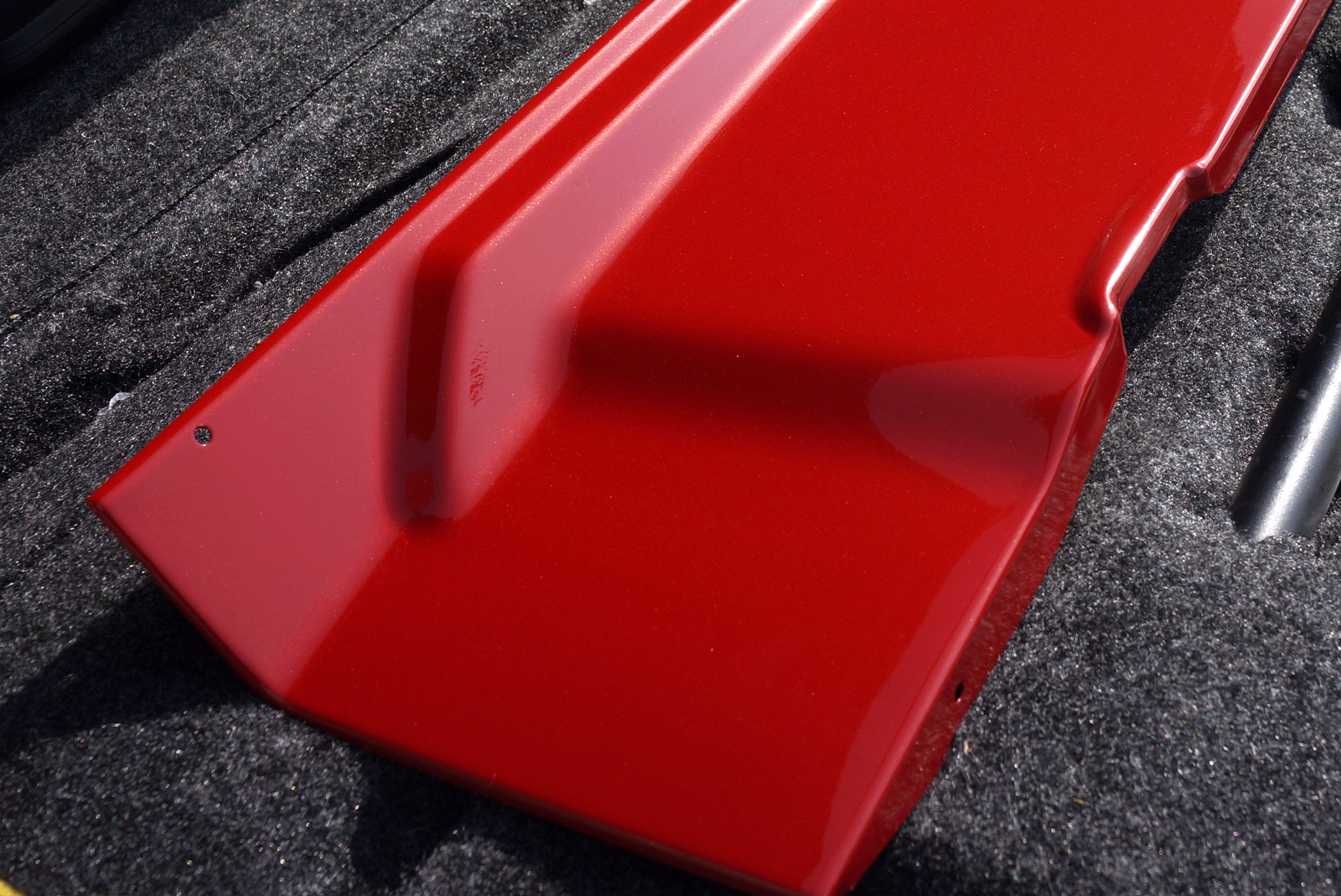

Some pics of the process so far:

The hood and approximate position of the vents:

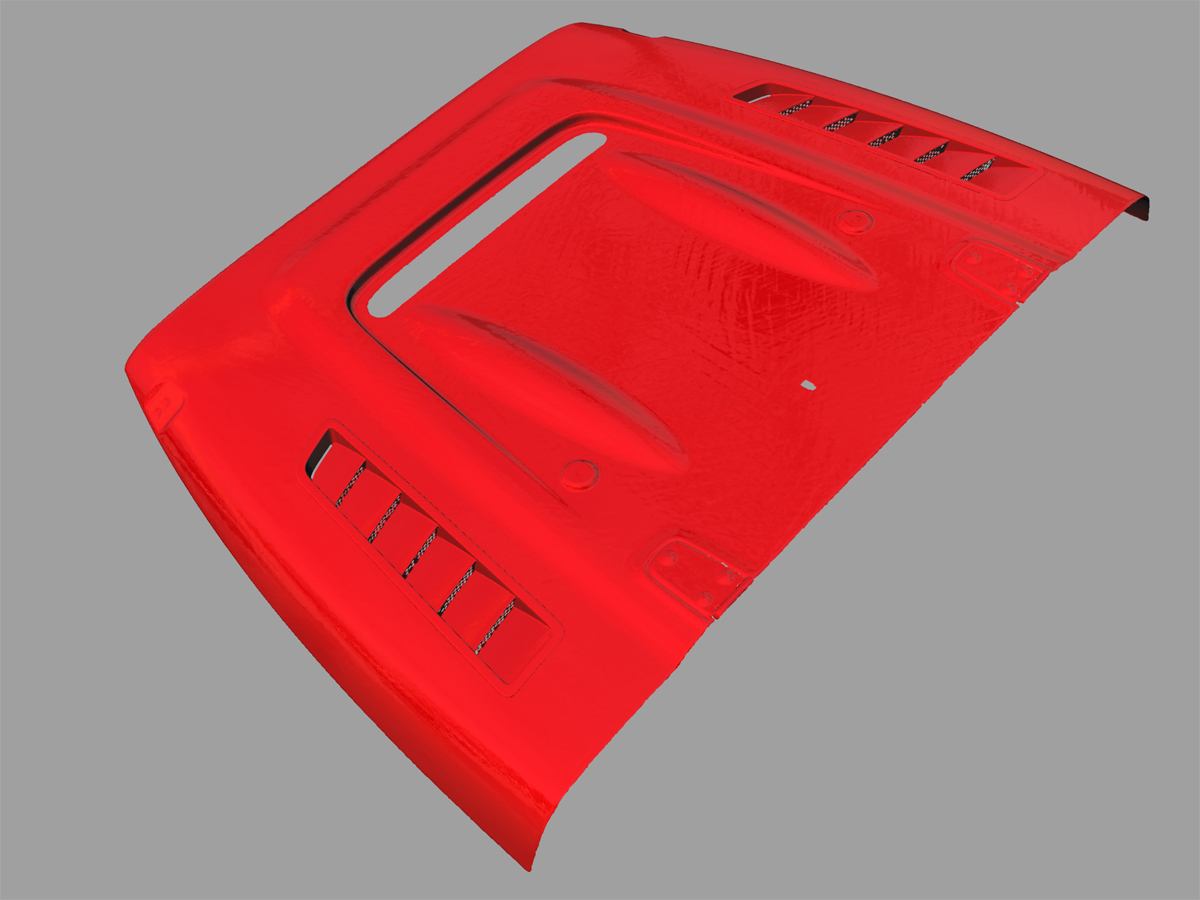

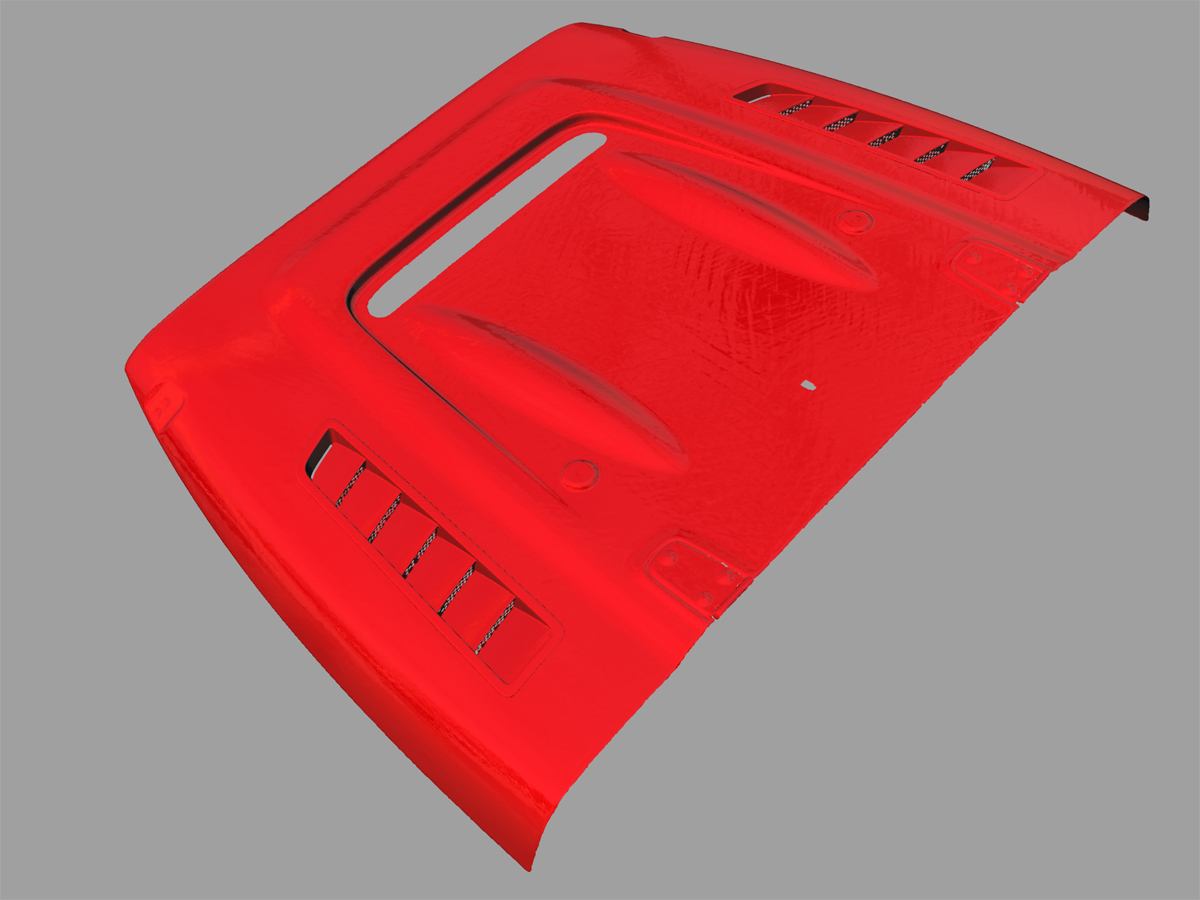

3D scan of the hood and the vents

Vents in place on the hood... time to start making the templates...

The body is also being prepped for paint... but we have one last body modification to finish up - a little enhancement to the hood.

Some pics of the process so far:

The hood and approximate position of the vents:

3D scan of the hood and the vents

Vents in place on the hood... time to start making the templates...

Last edited: