Well time for another long overdue update, this time I have a good excuse though

My wife and I had out first child, a healthy baby boy named Ethan. I took a month off of work, and I've managed to sneak some garage time in when the wife and baby are napping throughout the day.

I finished up work on the floors with the same lizardskin coating under the passenger compartment floor boards, as well as painting the frame where I am finished welding. The body is set back down on the frame and the truck is back to being a roller.

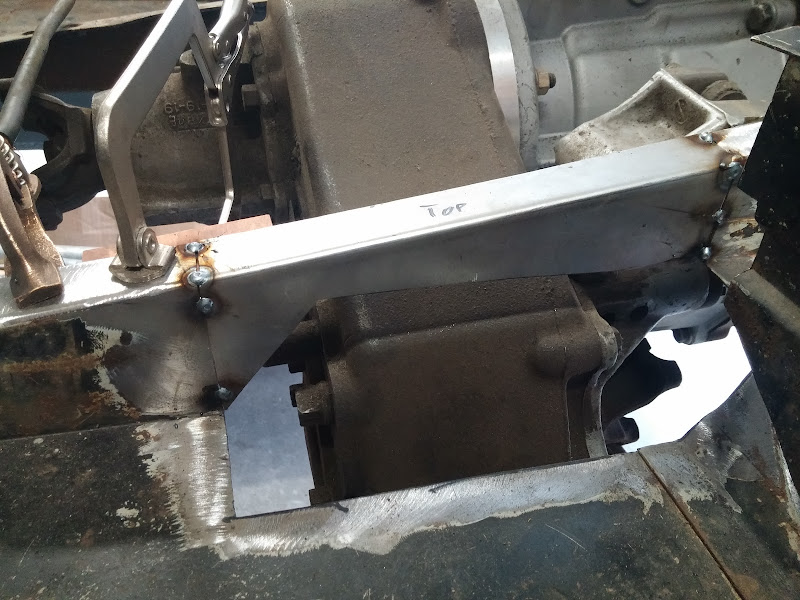

To finish off the floors I needed to fill in this gap I cut out to clear the transfer case.

Played with cardboard until I had a shape that I was happy with, then transferred the design to metal and used my buddy's brake at his house to make the bends.

First piece tacked in

The second (more complicated) piece didn't work out exactly like I planned, I didn't account for the metal shrinkage at the bend quite right, so I wounp up modifying it a bit but I'm still happy with how it came out. I still need to finish weld this in and grind it down smooth.

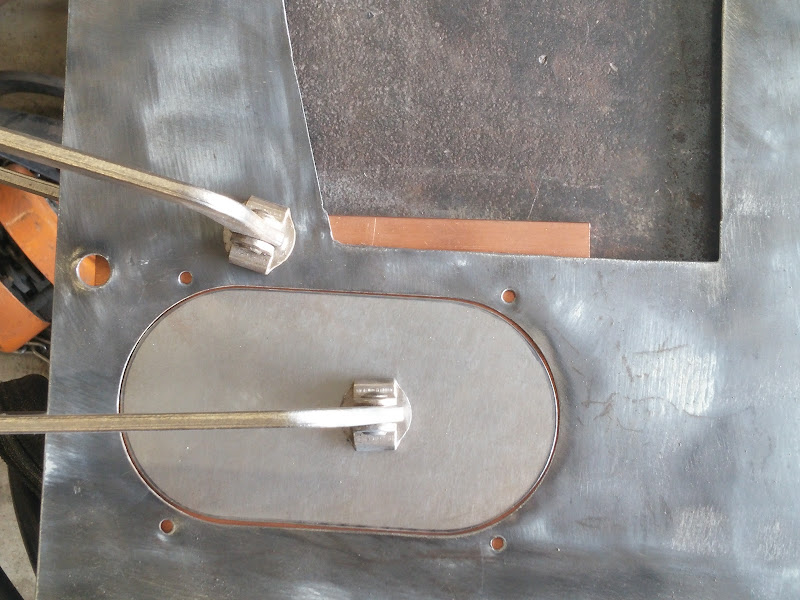

Next I cleaned up the transmission tunnel cover, opened up the shifter hole to fit the NV4500 shifter tower, and welded up the stock transfer case shifter hole. The transmission shifter is roughly in the same place as the stock one, but the t-case shifters will be quite a bit further back. I am still working out exact placement and will have to cut a new hole once I get that sorted out.

No more transfer case shifter hole. You can see i used a big piece of copper as a backer, really makes work like this pretty easy. I tig welded up the patch panel, makes for less weld to grind down after the fact.

Found a nice big Hurst shifter boot that covers the transmission shift tower, and the rest of the transmission and t-case fit nicely under the cover so I didn't have to modify it too much more.

To finalize t-case shifter location I wanted the seats to at least be mocked up into place. The seats I'm using are from a TJ Rubicon unlimited, and have a nice fold forward feature that should make getting into the back seat easier, so I wanted to keep the bases intact. This means cutting out the stock seat bases, and making some quickie mock up bases to let me play with height and position.

I'm going to cut out the bulkhead behind the seats, but I think with the seat flipped forward access won't be too bad, and I also can use the area behind/under the seat for storage.

Next steps - build some transfer case shifters & finish the floor mods, then pull the drivetrain for finish welding of more brackets on the frame, some firewall modification needed to clear the exhaust manifold, and pull the axles to finish weld the suspension brackets and re-gear. Then I'll actually be dropping the drivetrain back in for the (maybe) last time, and start plumbing and wiring.

Still in the garage, but getting close. 4 years now so far.