OverlandZJ

Expedition Leader

Thanks John! How's yours coming? ~ James

HA!... you know the situation. But i need to get it road worthy before September.

Again, very impressed with what you did here. :drool:

Thanks John! How's yours coming? ~ James

Yeah white... original right?

I decided to paint the top half of the Jeep white to match it, so white it is. I was gonna do desert tan, but figured white would be better in the long run.

I am working on an elevator for the entry into the tent on those types of nights...

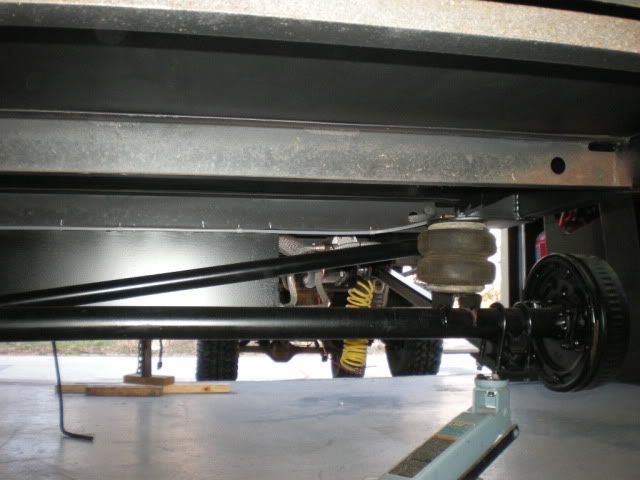

I decided to go ahead and build a custom suspension for it. I used my solid axle that I narrowed, and made a trailing arm set-up with a panhard bar. I used 1.5 (.25 wall) square tubing for the arms, and 1.5 round DOM for the panhard bar. Greaseable poly joints on the arms, and the trackbar/panhard, and everything is in double shear.