I'm building the side drawer unit today. I'll post some construction photos along the way, hopefully they'll help anyone thinking of building their own.

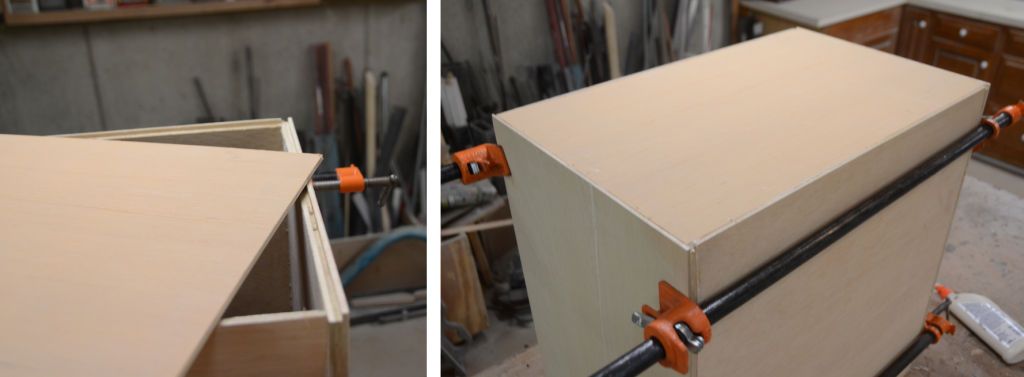

Here's the case assembled, clamped and waiting for the glue to dry, it's sitting face-down on the workbench. The sides, top and bottom are made from inexpensive 1/2" Sande plywood from Home Depot. The back is 1/4" plywood, I used flooring underlay plywood because I had a piece on hand and it's inexpensive. The case is the same height and depth as the enclosure I made yesterday and just wide enough to take up the rest of the available width in the back of the Jeep.

For a stronger front edge, I glued oak to the end grain of the plywood.

The cabinet is assembled with biscuit joints. Biscuits allow glue joints with no other fastners other than the biscuits, they're very strong and align the parts perfectly.

The rear panel sets in a rabbet on the back edge of the panels. It's glued in place and secured with a few brad nails. I made the rabbets on the table saw, which means they run off the ends of the panel, leaving a small void at each corner. To fill the voids I glued a small block of wood in each void, they'll be trimmed flush after the glue dries. The voids at the corner are visible in the photo below; the blocks glued in place are visible in the first photo in this post. The other way to cut the rabbets is with a rabbetting bit in the router, avoiding the corners, but I didn't have an appropriate side rabbeting bit on hand so I used the table saw.

I plan for the cabinet to sit flush against the kitchen enclosure I built the other day. Because there are bolts holding the enclosure to the kitchen base, I put clearance holes for the bolt heads in the side of the cabinet.

When the glue dries I'll test fit it in the Jeep and then I'll begin construction of the drawers.