-

Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barn Door for JK factory hardtops

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

How about a pic with the top on from the front angle to show off that new roof line to windshield interface?

The top is off the Jeep now, when I get back to working on it I can take more photos. It'll probably be a while before I get back to it though, I'm on an off-road trip in Colorado for the next 10 days, and when I get back I've got a couple of other projects that will have to take priority over the JK Safari Cab, like the JK Cargo Slide system I've been asked to design and prototype. But FWIW, the top of the windshield flows smoothly into the curve of the roof, not unlike how the roofline on the Jeep Africa concept looks.

What are you making a new sPod interface? Think that market is already covered.

I'm not doing my microprocessor-controlled accessory system as a product for the market - I'm doing it for my own personal use only. And what I'm doing will have more capabilities than sPod-like systems - I plan to interface it to the JK's CAN-bus and OBD-II system so it can work well with other systems on the Jeep. I'm also building custom programming features that products like the sPod don't have, like a keypad interface, and it'll have a 2-line alphanumeric display for status reporting on both CAN-bus/OBD-II controlled items and my own accessories. Think of it as a combination of an sPod and a ScanGauge II, plus a few things.

Kmrtnsn

Explorer

I'm working with two different companies right now that are interested in bringing the StoreGate to market. Cost estimates for doing the plastic shell are done, now the company is working on estimates for completing both styles - the locking door/table style and the cargo net style. That company has "first dibs" on it, if they don't go ahead with it, it seems likely the other company will.

Goog to hear Jscherb! Thanks!

jscherb

Expedition Leader

I've been in Colorado for the past two weeks, exploring trails in my LJ Safari. I spent the last two days in Silverton, where the local Jeep rental/tour place has several old Suburbans with the center of the roof cut out for better mountain views; they've got a snap-on canvas cover for the roof when the vehicle isn't doing a tour. It's not the best tailored piece of canvas ever, but it works...

Something like that is in my plan for the JK Safari Cab, although a bit better tailored. The Safari Cab already has a large opening in the roof and a frame all the way around:

I'm thinking something more like a truck tonneau cover than the canvas on the Suburban above.

Something like that is in my plan for the JK Safari Cab, although a bit better tailored. The Safari Cab already has a large opening in the roof and a frame all the way around:

I'm thinking something more like a truck tonneau cover than the canvas on the Suburban above.

Mass_Mopar

Don't Litter

Looking good!

jscherb

Expedition Leader

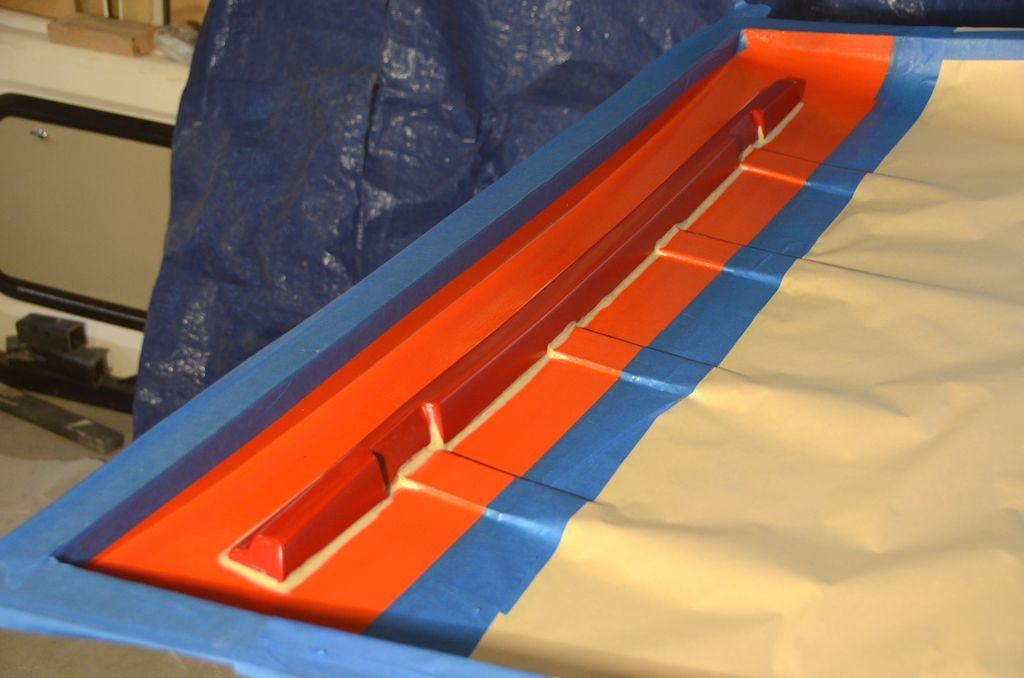

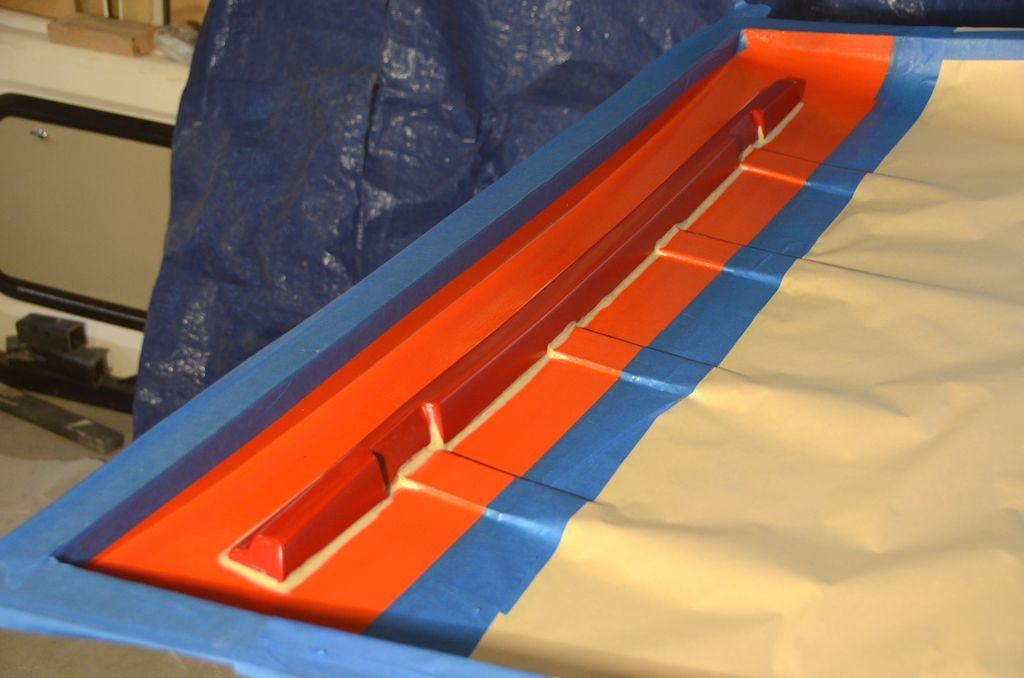

I haven't been able to make any progress on the JK Safari Cab for the past month due to other projects like the cargo slide, travel, etc. Today I'm back on it - I'm making the mold for the last required fiberglass part - the windshield header. This part will get bonded into the inside of the roof, and will be where the latches mount to secure the roof to the windshield.

I've made a wooden master for the part (the red part), and it's held into the roof mold with double-sided tape. The reason it's in the roof mold is so I can form a flange on the part that exactly matches the contour of the roof. Modeling clay is used to form a nice fillet between the master part and what will become its mounting flange.

In the photo above it's waxed and had the mold release sprayed on it, as soon as the mold release dries I'll begin the fiberglass work.

Today I'll make the mold, and tomorrow I'll use the resulting mold to make the header.

I'm also scheduled to have a call today with a company that's interested in the Safari Cab.

I've made a wooden master for the part (the red part), and it's held into the roof mold with double-sided tape. The reason it's in the roof mold is so I can form a flange on the part that exactly matches the contour of the roof. Modeling clay is used to form a nice fillet between the master part and what will become its mounting flange.

In the photo above it's waxed and had the mold release sprayed on it, as soon as the mold release dries I'll begin the fiberglass work.

Today I'll make the mold, and tomorrow I'll use the resulting mold to make the header.

I'm also scheduled to have a call today with a company that's interested in the Safari Cab.

Comanche Scott

Expedition Leader

Keeping my fingers crossed. I would really like to see this and the barndoor come to fruition! :beer:

Comanche Scott

Expedition Leader

Just thought of something. I picked up a liner for the soft top. I *think* it is a Bestop piece. Anyway, It's a double thick material with a matting in the middle. Supposedly for sound/heat reduction. Might be a neat thing to do with your "soft roof" concept.

jscherb

Expedition Leader

Looks amazing. Hoping the Safari Cab makes it to production for a JKU sometime soon, I would buy today.

Keeping my fingers crossed. I would really like to see this and the barndoor come to fruition! :beer:

There are two companies that currently seem to have interest in the top, there was a third but I haven't heard from them in a while. It was an interesting call with the one company yesterday, they want to work on a very tight timeframe for an upcoming show and I don't know if that timeframe works for me with all of my other commitments. They also want a second version in time for that show that would require some new fiberglass work. I'll continue talking to them but I don't know if it'll work out given the schedule they're shooting for. I didn't discuss the idea of the barn door being a separate product with the company yesterday, based on what I know about them I suspect they would only be interested in selling complete hardtops.

jscherb

Expedition Leader

Yesterday I made the mold for the hardtop windshield header; today I used that mold to make the header itself. Clockwise from top left:

- The mold as it looked when I finished yesterday, the fiberglass layup is complete and it was left on the master parts overnight to cure.

- This is what the mold looked like when I popped it off the master this morning. It is shown right after I trimmed the rough edges of the fiberglass off; they're dangerous so trimming them off right away is important. I haven't washed the mold release off yet.

- The mold shot with white gelcoat as the first step in making the header

- The fiberglass layup of the header is finished. I'll let this cure overnight and pop the header out of the mold tomorrow morning. I've embedded metal plates in the fiberglass to serve as nut plates for attaching the latches.

- The mold as it looked when I finished yesterday, the fiberglass layup is complete and it was left on the master parts overnight to cure.

- This is what the mold looked like when I popped it off the master this morning. It is shown right after I trimmed the rough edges of the fiberglass off; they're dangerous so trimming them off right away is important. I haven't washed the mold release off yet.

- The mold shot with white gelcoat as the first step in making the header

- The fiberglass layup of the header is finished. I'll let this cure overnight and pop the header out of the mold tomorrow morning. I've embedded metal plates in the fiberglass to serve as nut plates for attaching the latches.

Last edited:

Comanche Scott

Expedition Leader

Well I certainly understand your trepidation with such a time line. This is supposed to be fun, after all.

If there is interest today, and the number of JKs keeps growing, there will be interest when you are ready.

If there is interest today, and the number of JKs keeps growing, there will be interest when you are ready.

jscherb

Expedition Leader

Here's the header just out of the mold, and after a preliminary trim and washing off the mold release. It'll get trimmed a bit more as it's fitted into the roof.

This was the last required piece I needed to mold before final assembly of the JK Safari Cab roof can be done, so as soon as I get some time I'll begin final assembly.

This was the last required piece I needed to mold before final assembly of the JK Safari Cab roof can be done, so as soon as I get some time I'll begin final assembly.

jscherb

Expedition Leader

Early in this thread I posted some pictures of a tailgate storage compartmnt/trail table I had designed and build a few prototypes of, I call it the StoreGate. I've been testing a prototype in the JK for a while.

When open, the door serves as a trail table.

Thursday I met with a company about it and they've signed up to manufacture it and bring it to market. Probably will take a few months to get into production. I think their plan is to show at least a preproduction version at the SEMA show in the beginning of November.

I've also had one installed in my LJ for quite a while. I don't need a table in the LJ so that one has a cargo net instead of the table. I think the company plans to offer the StoreGate both ways - with a door/table or with a net.

When open, the door serves as a trail table.

Thursday I met with a company about it and they've signed up to manufacture it and bring it to market. Probably will take a few months to get into production. I think their plan is to show at least a preproduction version at the SEMA show in the beginning of November.

I've also had one installed in my LJ for quite a while. I don't need a table in the LJ so that one has a cargo net instead of the table. I think the company plans to offer the StoreGate both ways - with a door/table or with a net.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 2

- Views

- 2K

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 2K