jscherb

Expedition Leader

Very cool! Nice to have someone to work with. It's both motivating, and fun.

A lot of times I prefer to help friends work on their stuff to working on my own, just for that reason.

Looking forward to seeing how they come out and go together.

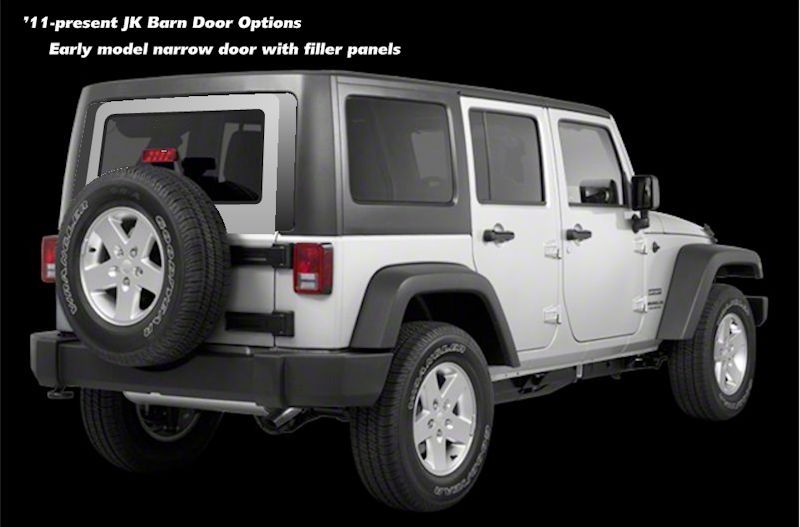

Thanks. It's been fun working with Tom - he's joined up with me on this project because he wants to learn fiberglass, and because he wants a barn door on his JK. He'll get both out of this project. He's learned fast and does great work - he did the outer skin mold last night without any help from me, and it turned out great.

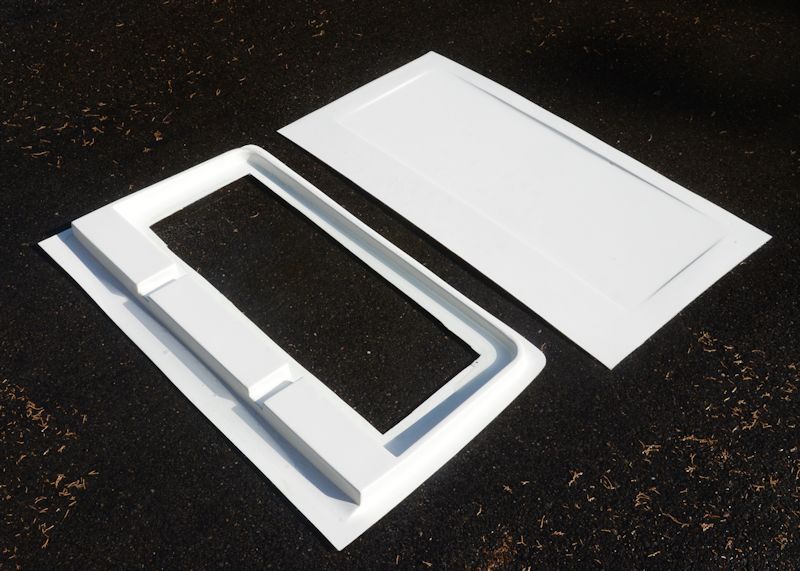

I'm in the process of molding the first set of parts right now (without Tom, he's got a day job unfortunately). They'll be finished this afternoon and then they'll cure overnight and I'll pop them out of the molds tomorrow morning. I'll post photos of the parts tomorrow as soon as I pop them out of the molds.