Motor Mounts Part 2

How can something as simple as motor mounts take two days to fab!?!

I started out by adding a top gusset to the motor mounts. This was to provide front to back stability to the mount. Because of the design of the main mounting plates, I had to bend the little tongue over and fit it. It was a pain, but worth it in the end.

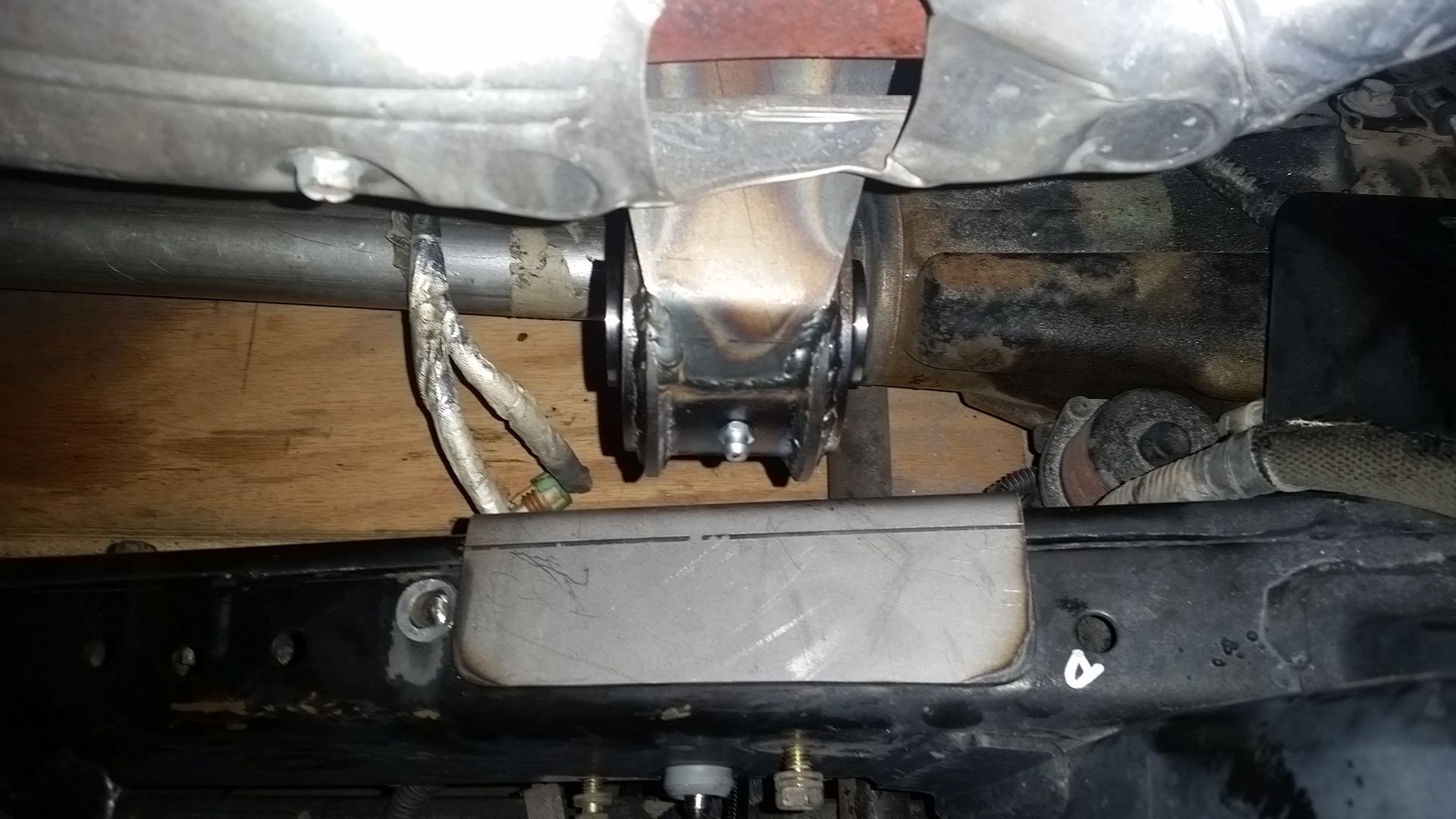

The engine side of the mounts are now done....I think....

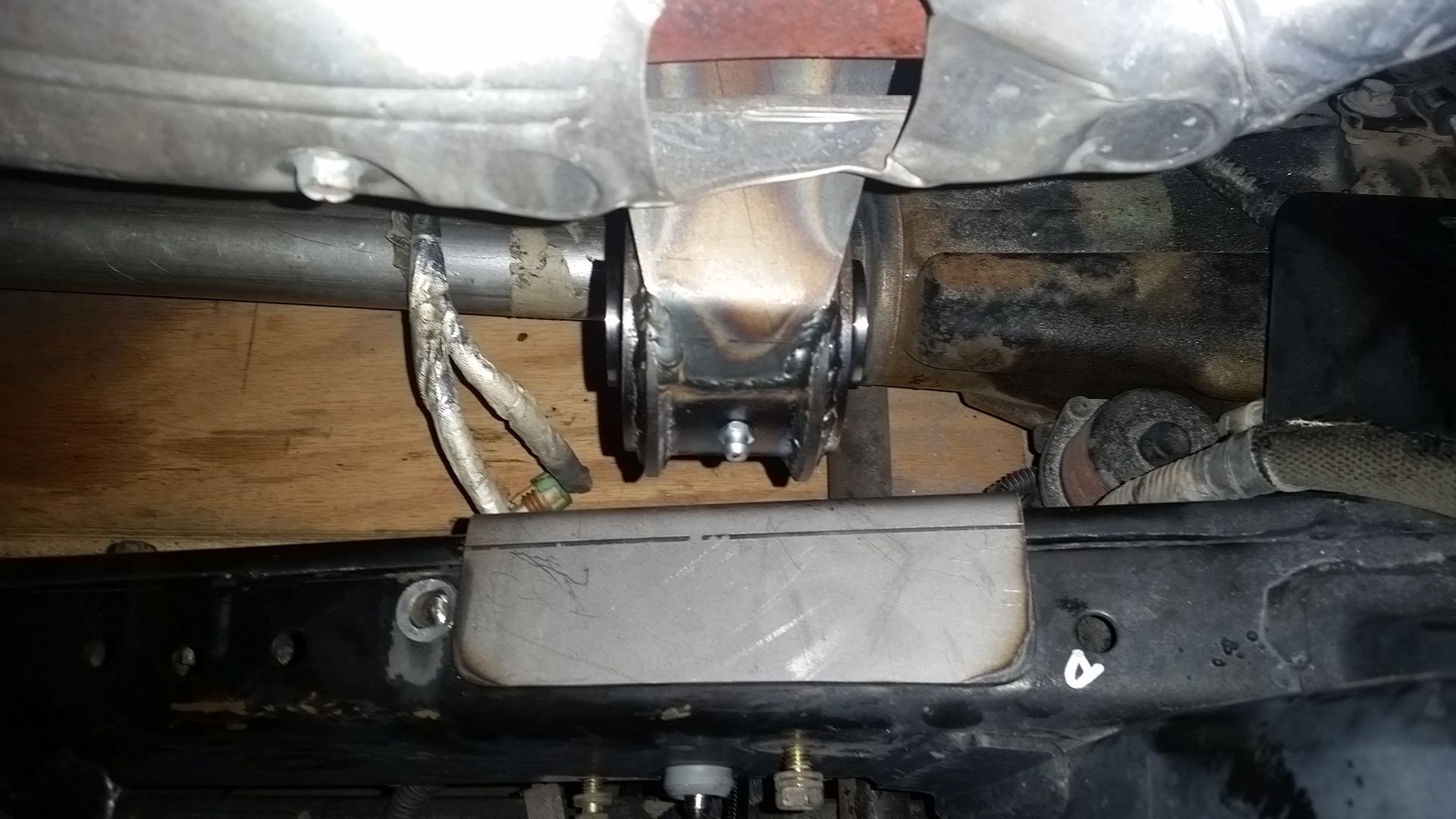

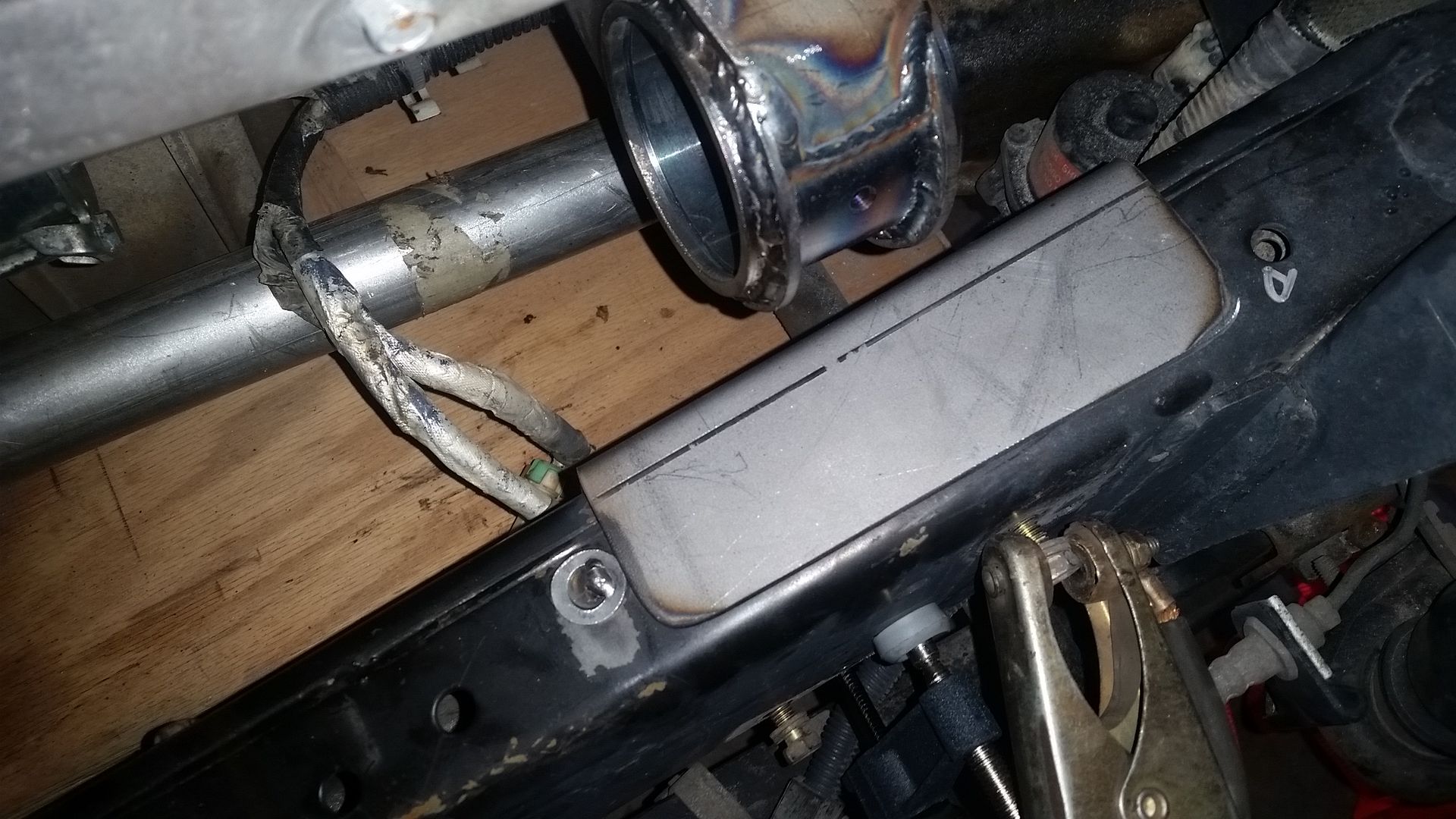

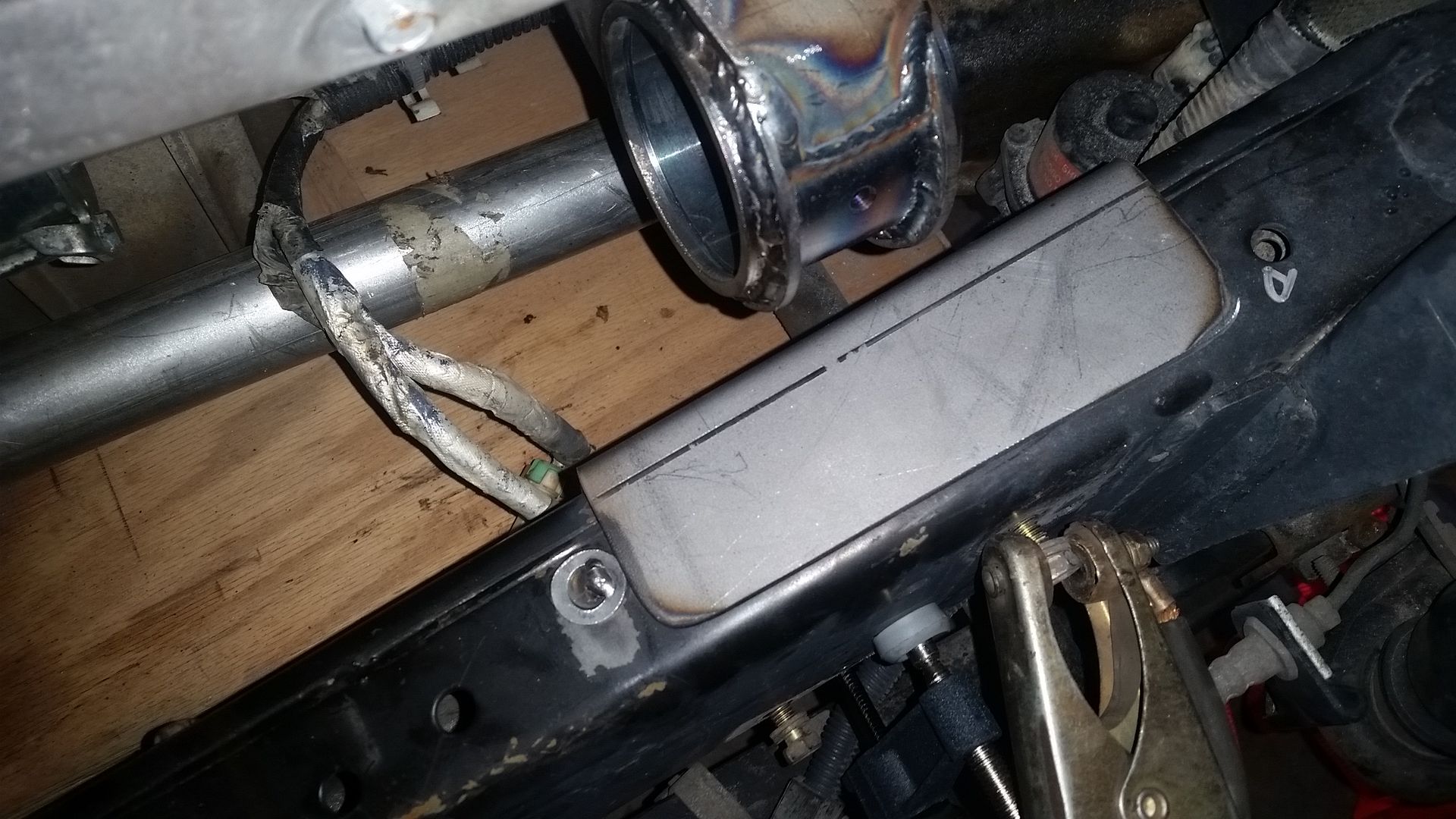

Once the engine side mounts where assembled, I started construction of the frame side. I decided to use a frame pad where the mounts on the frame will be. This allows the mating parts to be fabricated and tack welded in place to the frame pad with everything assembled. Then I can pull the frame pad out with the tacked in place mounts for final welding.

Tip of the day. If you make these frame pads, bend a 90 flange in the top if you have room. This gives you a nice repeatable reference point for the vertical position. The inside is also hard against the frame. The only other direction it can move is fore/aft along the frame.

If you tack weld a washer to the frame, you end up with a nice simple reference point for that direction. This means you can remove and replace the part and not lose the position on the frame. It will hold up to a light hit, or if you need to clean the frame with a scotch-bright pad or wire wheel.

My favorite tool of the day. This is one of those 12" diameter disc sanders from Harbor Freight. For what it cost, FANTASTIC. It is so nice to be able to have a decent platen to square up parts and it also makes fast work of rounding off corners. Highly recommended.

Once I had the engine side bolted in place and the frame pads located, it was time to start connecting the frame to the engine FINALLY!

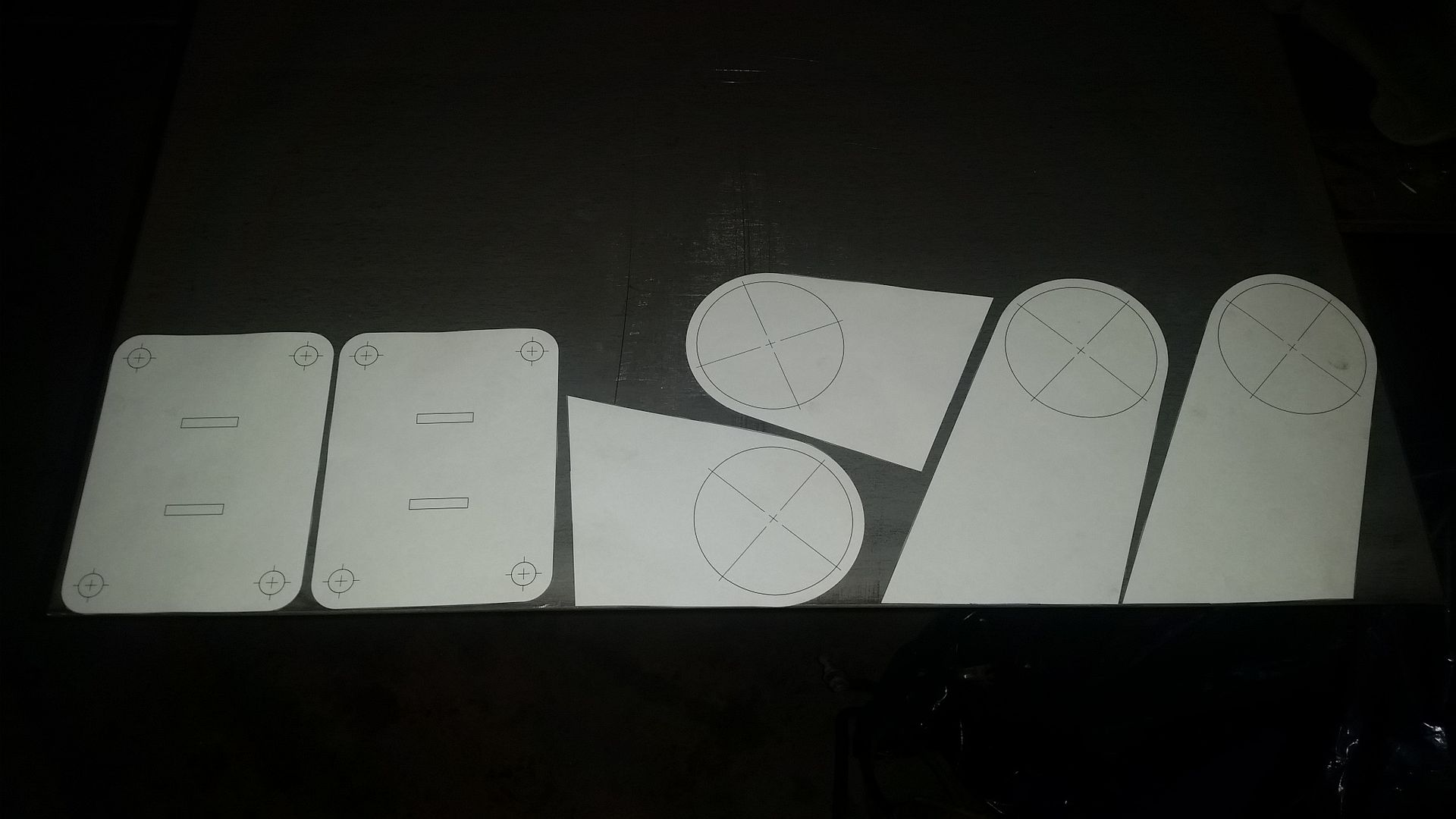

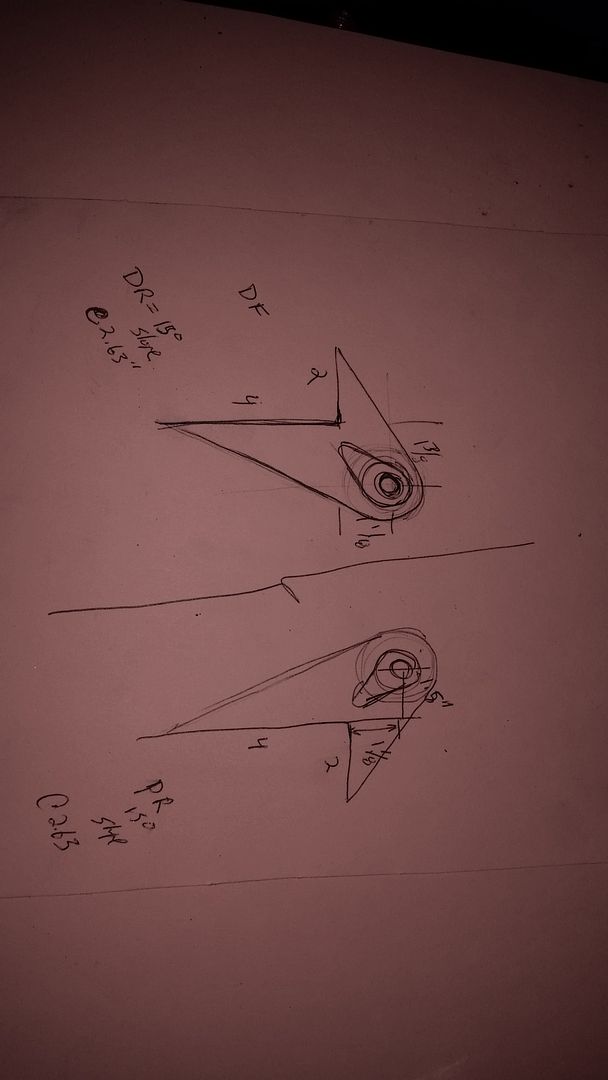

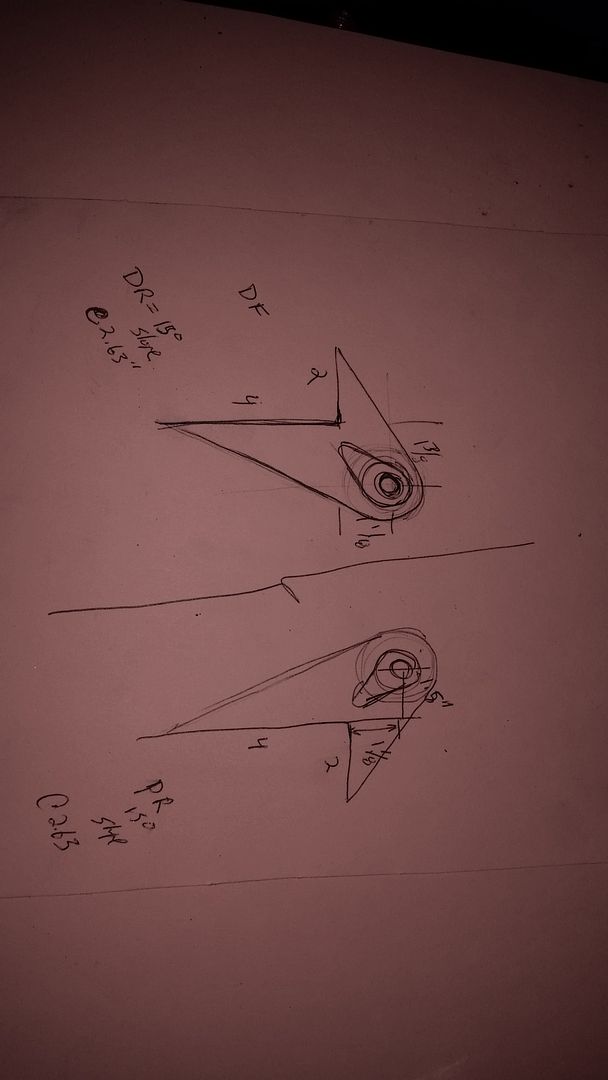

This was much lower tech than the computer. I took some rough measurements. Then made some quick poster board mockups to dial in the position of everything. Once I got within about 1/16" I moved over to foam board.

This is where I stopped for the night. I have one more tweak to the frame side mounting patterns that can be done when I turn them into metal. Overall I am pretty happy with how simple and symmetrical the frame side mounts turned out. I think the mounts where within 1/16-1/8" of being the same.

Once these are in metal I will install them, tack weld in place, remove the frame side mounts, final weld them, add gussets, clean the frame where the pad will be welded, and then final weld the frame pads into place. I guess there will have to be a part 3 for motor mounts....gees....little time suckers!