Stoffregen Motorsports

Explorer

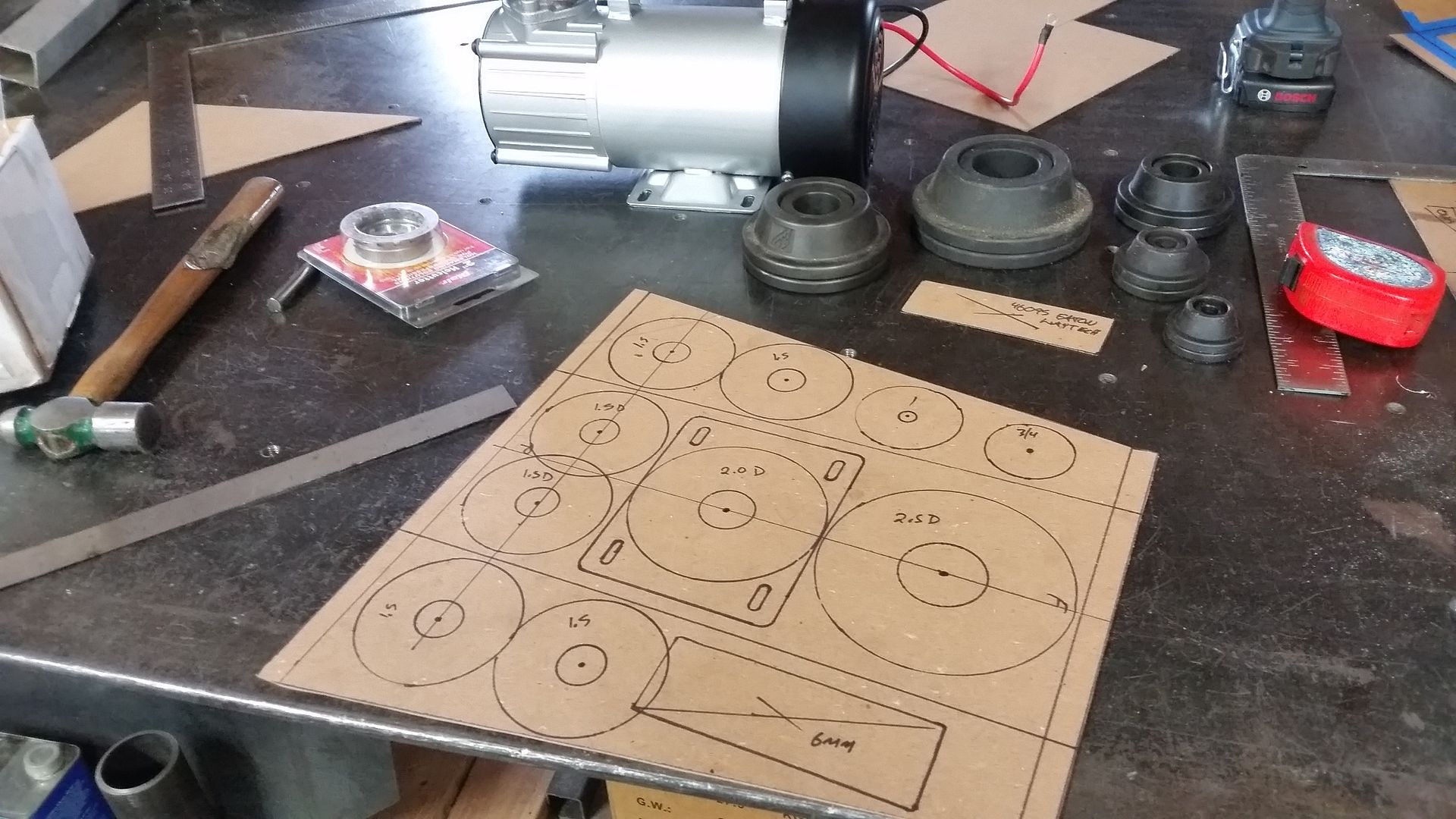

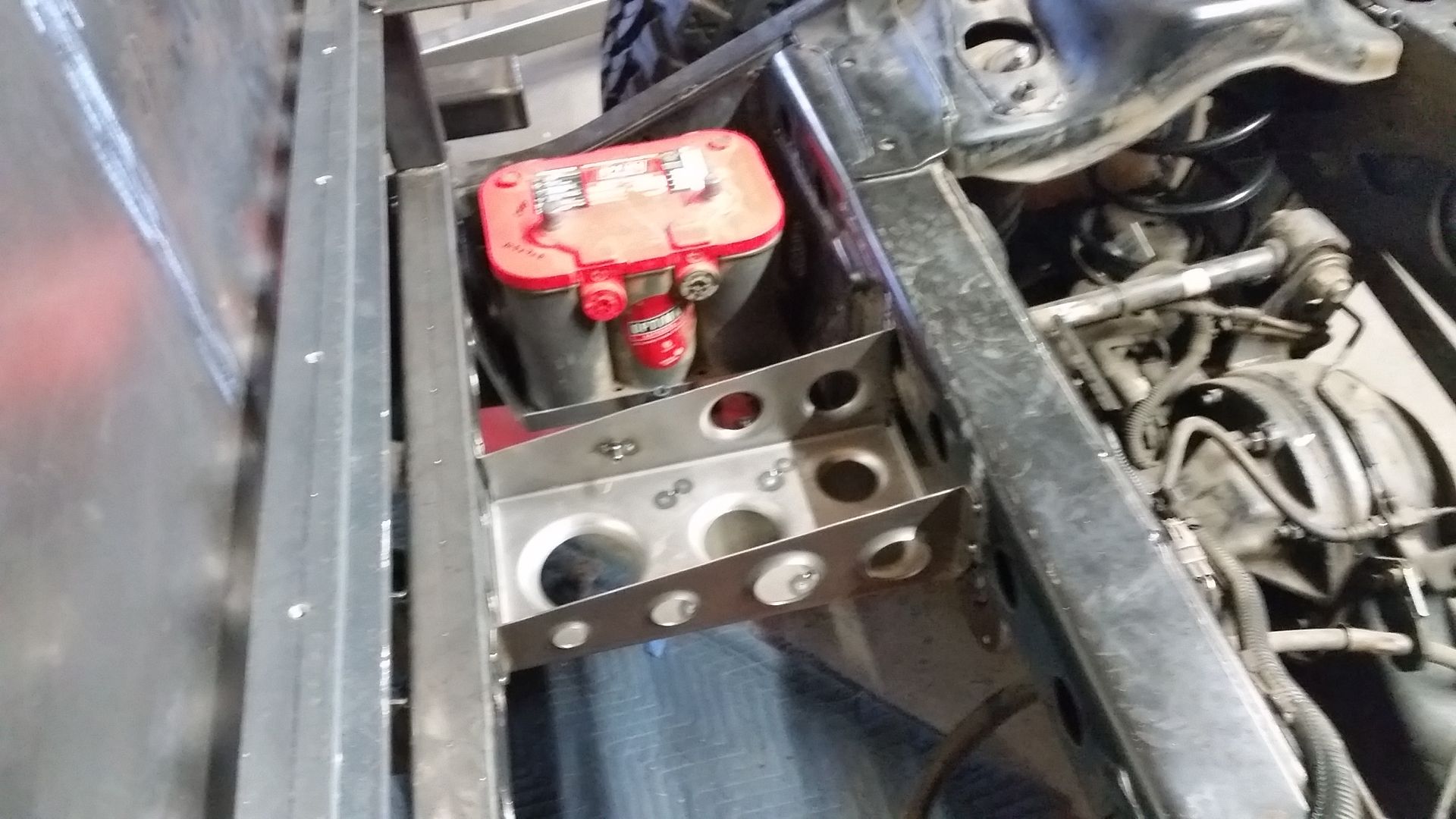

Well thought out details...

Get your tickets to THE BIG THING 2026!

Incredible work. As far as tag location, i ask where are you mounting spare tire? In bed? Swing away?

Sent from my SM-T810 using Tapatalk

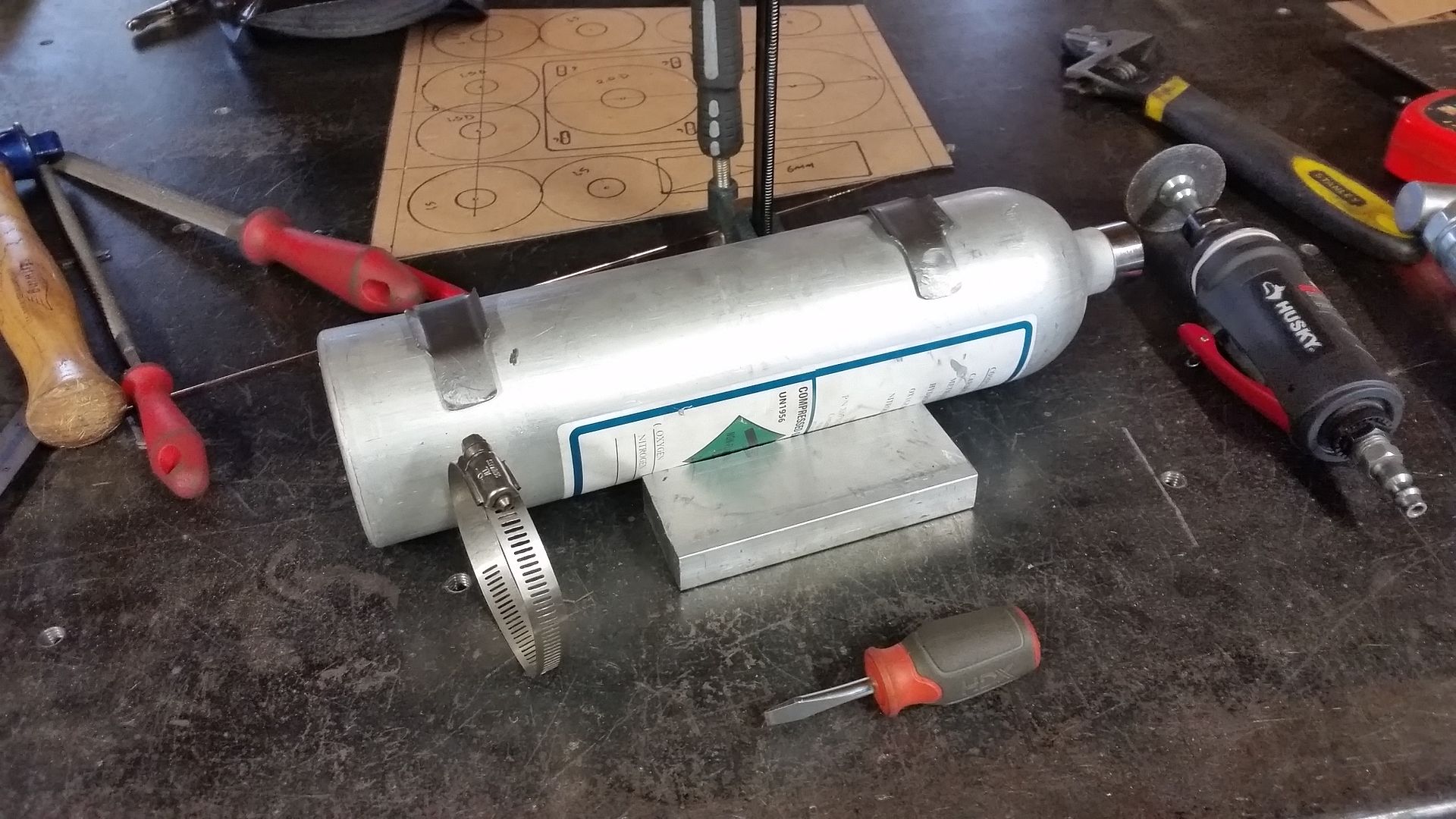

The fuel consumption is naturally large, like this large and medium-sized devic

Maybe he was suggesting jerry can holders on the rear bumper. Extra fuel...?