Under hood LED strip lighing - Installation

INSTALLATION

Now that all the parts and supplies were in order, it was time to install the lighting.

The first thing I did was to cut a length of LED strip. I simply held it up in place under the hood, marked and cut. If you look at the following picture, I've indicated the correct locations to cut. You'll notice that there are three LEDs between each cut line. Therefore, you have great flexibility in how long you want the strip to be. However, if you were to cut in locations other than where I've indicated, then you'll end up with a few dark LEDs.

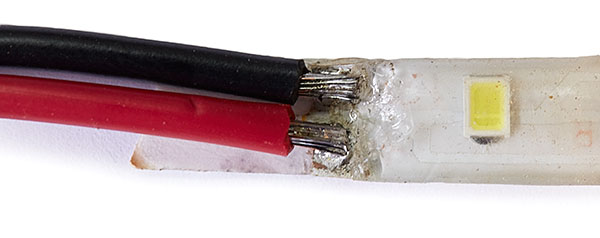

When purchasing the LED strip in a reel, one end will have short lengths of wire already attached. I removed these and soldered on my own. I removed the white protective tubing first and then cut off the wires.

To fully remove the wires and access the solder points, I used a utility knife to remove the clear spongy weatherproofing and used a soldering iron to remove the stock wiring.

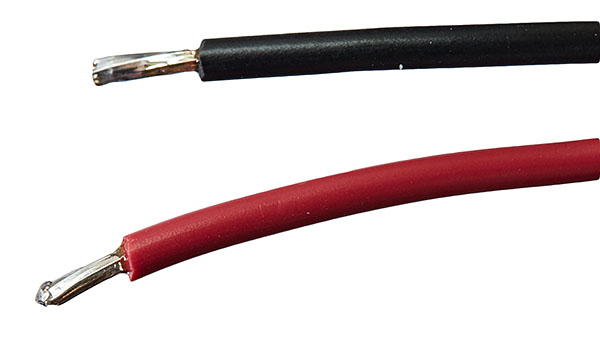

Next, I cut two lengths of wire. I eye-balled the length and gave myself some extra. The LED strip will be attached at the top of the hood, so I needed wire to span the length of the hood down to the hood hinge and then forward to the front of the vehicle. About eight feet of each wire gave me plenty to work with.

I stripped one end of each wire about 1/4" and tinned with solder.

I soldered the wires to the connection points on the LED strip. Make sure you pay attention so that the wires are soldered to the correct points. There is a small positive '+' sign that tells you which pad to solder the power to. If you do this backwards, the lights will not illuminate.

After soldering on the wires, I cut some braided sleeving and slid it up over the wiring all the way up to the LED strip. I then cut a 2" piece of adhesive-lined heat shrink tubing and slid this over the sleeving. This needed to cover the end of the sleeving, exposed wiring, and part of the LED strip. Finally, I used a heat gun to shrink and seal in place.

Next, I cut a short piece of 3M double sided tape and attached to the underside of the LED strip at this connection point. Although the LED strip has an adhesive back and I'll be using cable tie mounts for the wiring, I wanted an additional attachment point directly at the wire connection. This will help to minimize any vibration, which might weaken the connection.

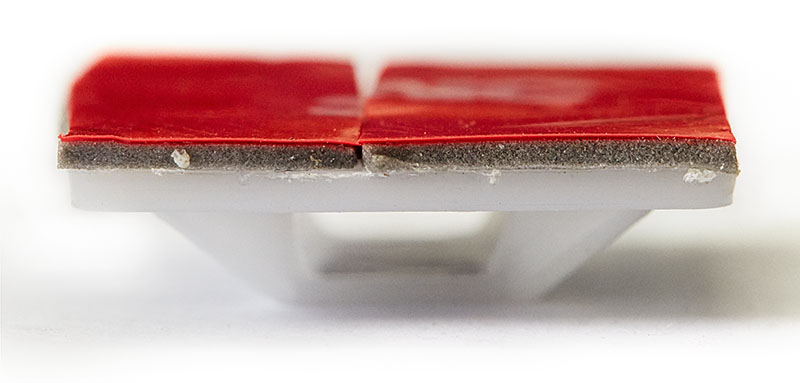

My experience with cable tie mounts is that the adhesive is not very strong. Therefore, I removed the sticky adhesive that came with the mounts and added my own using the 3M double sided tape. I ended up using four cable tie mounts so this isn't very tedious.

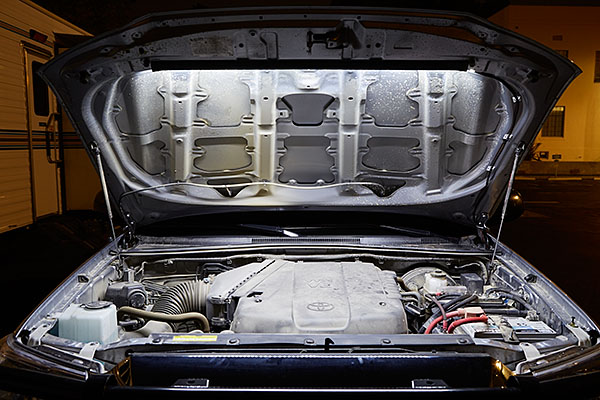

Next, I attached the flexible LED strip. Of course, I needed to make sure that the location where I was placing it was perfectly clean. I started with a degreaser to remove any dirt and grime. Then I wiped down the area with denatured alcohol. As you can see in the following picture, I didn't need to clean the entire hood, only the area necessary.

After this, I attached four cable tie down mounts spaced evenly down the hood from the LED strip towards the hinge.

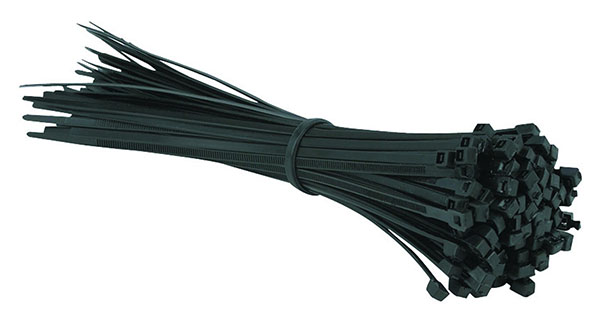

I used 4" zip ties to secure the wiring to the cable tie down mounts.

I used one heavy duty zip tie at the hinge.

Next, I navigated the wiring under the grill and into the engine compartment. There was no need to remove the screw that attaches it to the body. There is ample space under it to slide the wiring through.

This is how it looked at this point.

My vehicle has a Bussmann RTMR installed as a secondary fuse/relay block. This allows me to add electrical accessories to the vehicle without using the OEM fuse block. If you don't have one of these, then your wiring will be slightly different. But this is very easy to do. Use an appropriate connector to attach the red wire to your battery with an in-line fuse. The black wire will attach to the bottom of the pin switch, as you'll see in a moment. Finally, connect an optional ground wire from the pin switch to a suitable ground.

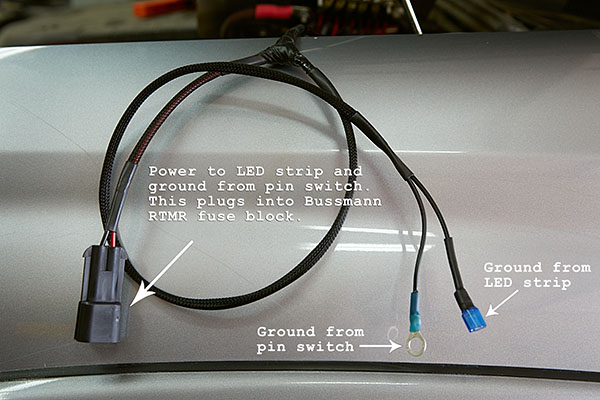

Anyway, I cut the wiring to length and attached my connectors, which are outlined in the following picture. I used a Metri-pack connector to connect to the Bussmann RTMR.

Now it was time to install the pin switch and complete the wiring. The easiest location for the pin switch in my 2015 Toyota Tacoma that didn't require any drilling was to use the headlight mounting bolt on the driver side. So I began by removing this bolt.

Once removed, you'll see a plastic threaded clip underneath.

I removed this clip with a pair of needle nose pliers. I just had to squeeze the bottom, push it up, and then wiggle it out from between the body and headlight mount.

Finally, I dropped the pin switch down into the hole, but didn't secure it just yet.

Although I've recommended installing an additional ground from the pin switch to a better grounding point, this isn't required. Many people use the direct contact of the pin switch mounting bolt to the body of the vehicle as their ground. So if you're not installing an additional ground wire, you can secure the pin switch in place now with the lock washer and nut.

Otherwise, I first slipped the ring terminal from the additional ground wire onto the pin switch from the bottom. Then I tightened everything up with the lock washer and nut. The other end of this wire terminates ground within the Bussmann RTMR. Yours might connect directly to the battery, for example.

Last, I installed the ground wire from the LED strip to the spade terminal on the bottom.

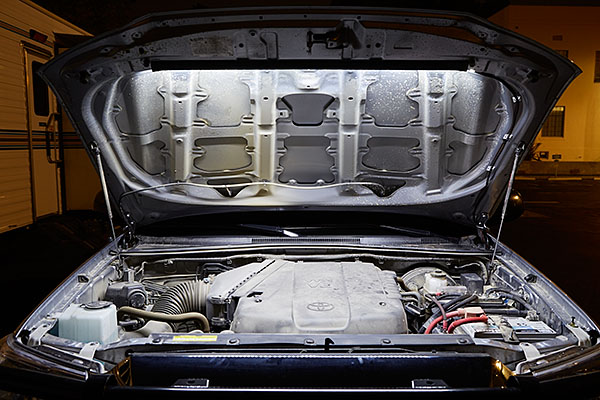

The installation was complete, so I reconnected my negative battery cable to finalize everything. I was immediately greeted with a wash of light in my engine bay. Awesome!