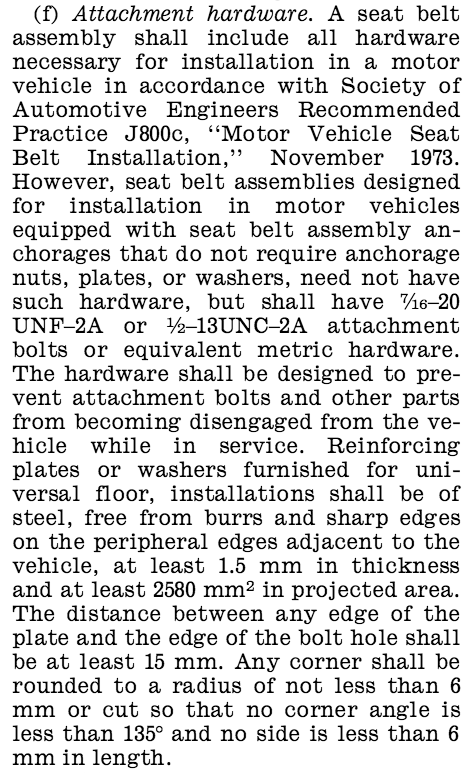

My rear seat platform is complete with the exception of bolting it in. I was held up because of a missing bolt. Basically, there's a total of six bolts to secure the rear seat brackets and four bolts for the seatbelts. To secure the platform, I'm using three of the mounting points for the rear seats and will plug the remaining unused holes with bolts. Unfortunately, I lost one of the 12mm bolts that secured the middle seatbelts. What's weird is that a replacement bolt from the hardware store wouldn't thread despite it being the same size: 12mm x 1.25 fine thread. Anyway, I had to go to the dealership today to get a replacement bolt. The parts guy was kind enough to give them to me for free, because I took the time to open up the Flippac and show him. Awesome!

Alright...here's the final steps.

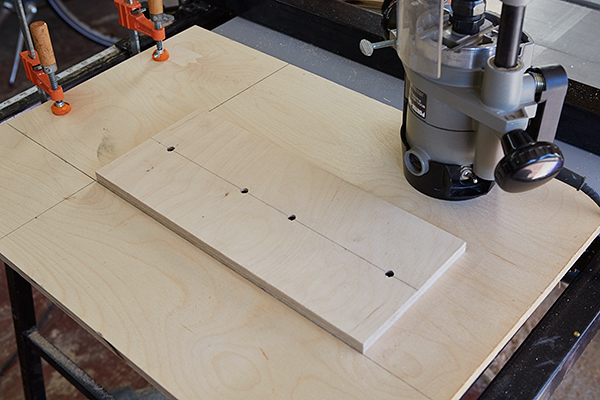

I wanted access holes to utilize the storage compartments underneath the platform. So I began by cutting a piece of plywood 6" x 14", which is the size of panel that I wanted. This was secured to another piece of plywood that will then become a template to use with a router.

With a 3/8" guide bushing and a 1/4" router bit, I followed the pattern, and the template was complete.

The template will be used on the platform to cut out the access compartment holes while simultaneously making the panels. While doing so, the panel needs to be temporarily secured from underneath. Otherwise the panel instantly floats when you complete the cut, and this is a good way to ruin it. I used scrap plywood.

I made the template in such a way that I can align it with the edges of the platform, which places the cutouts exactly where I want them.

I used the same guide bushing and router bit to cut out the panel.

After the first cutout, I flipped the template, re-positioned it, and cut out the second panel.

I then cut two finger holes in the panels to be able to remove them.

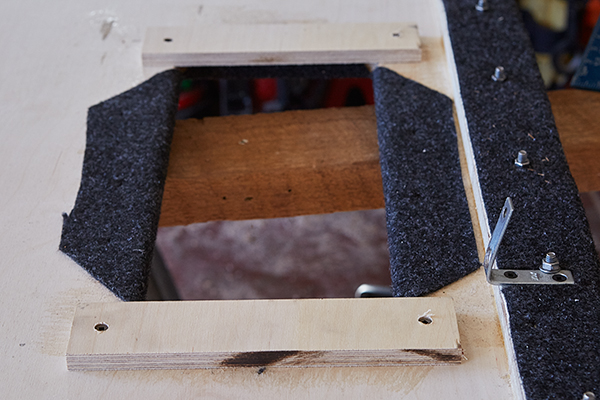

The next step was to cover the platform and panels with carpet. I used a very thin

carpet that is typically used for speaker cabinets and road cases. I purchased what I needed from

www.diyroadcases.com. I used

3M Hi-Tack 76 spray adhesive as well as 1/4" crown x 5/8" staples.

To prevent the panels from falling all the way through, I attached small strips of plywood on the bottom.

The front L-Track was simply bolted with hardware that I left standing proud on the underside. I don't think this will be a problem with anything hitting or catching them. Also note that I used Loc-Tite on all of these bolts.

The rear L-Track was bolted all the way through as well, but I recessed the nut using a forstner bit and cut off the extra length. This was necessary so that the platform sat on itself instead of the bolts. This didn't need to be pretty.

And here it is finally in the vehicle. I'll take another picture later with it in action.