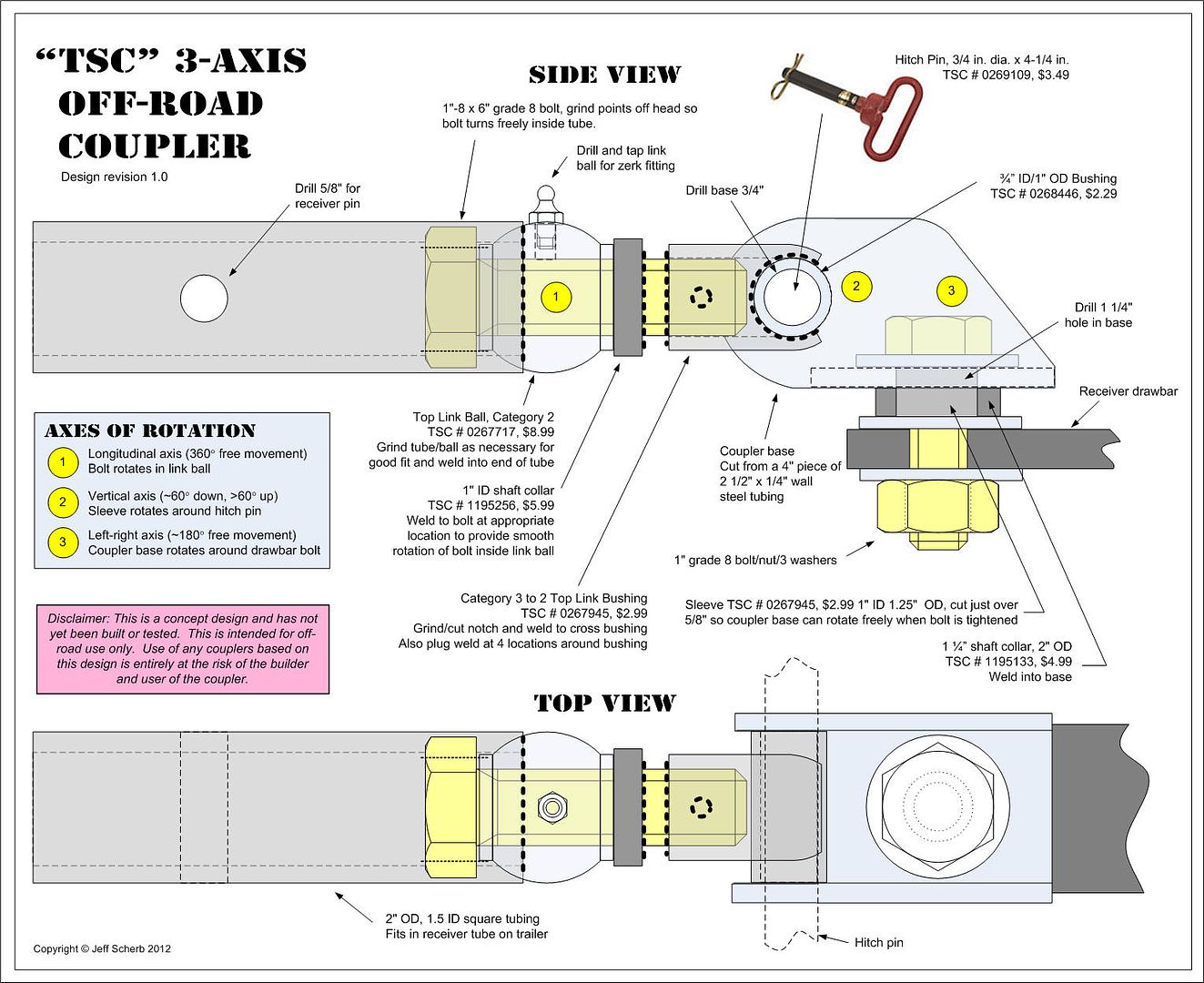

In keeping with the budget theme of this project, I've been thinking about an economical way to DIY-build a 3-axis off-road coupler. I built the HF trailer frame with a receiver on the tongue so it would be possible to easily swap couplers, and ever since then I've been working on a 3-axis design in the background.

The 3-axis couplers that are commercially available are in the $200 range. Kilby's Max Coupler is a particularly nice one, it sells for $225. Another high-angle option would be a pintle/lunette eye combination, according to Tractor Supply prices for that setup would run about $125.

My first goal for a DIY-design was that the cost of the parts should be less than $50. That doesn't include a receiver ball mount to go into the vehicle reciever, or a receiver tube to mount on the front of the trailer. Neither of those are included in the $225 price of the Kilby coupler, so I figure it's fair not to include them in the price goal.

My second goal was that all of the parts should be easily obtainable, and no fabrication work should be required that couldn't be accomplished with a drill, a hacksaw, an angle grinder and a welder.

I'm calling the design I've come up with the "TSC" 3-Axis Coupler, because pretty much all of the parts can be gotten off-the-shelf at Tractor Supply. Most of the parts are in their "3 Point Hitch Parts" section of parts for farm tractor implement hitches. I figure if these parts are strong enough to drag plows through fields, they should be able to haul our 2000-lb. or less trailers along the trail

.

All of the TSC parts can be purchased for less than $40, which leaves $10 to find a roughly 4" long scrap of 2 1/2" square x 1/4" wall tubing and about 8" of 2" square x 1/4" wall tubing.

Here's a drawing showing the basic idea:

Some fabrication experience would be very for this project because of the cutting and modification of some of the TSC parts, and competent welding skills will obviously be required for safety.

I plan to build one of these to test, but I won't be able to get to it for about two weeks because of some other commitments and work on another project that I want to get done first.